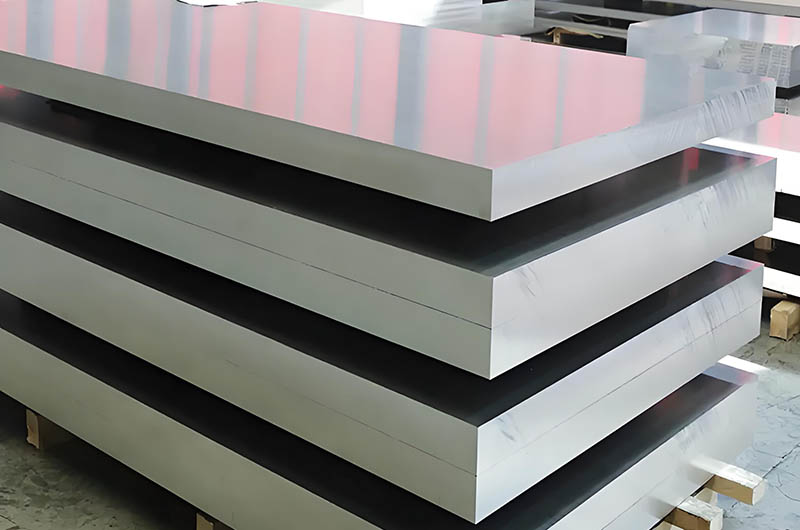

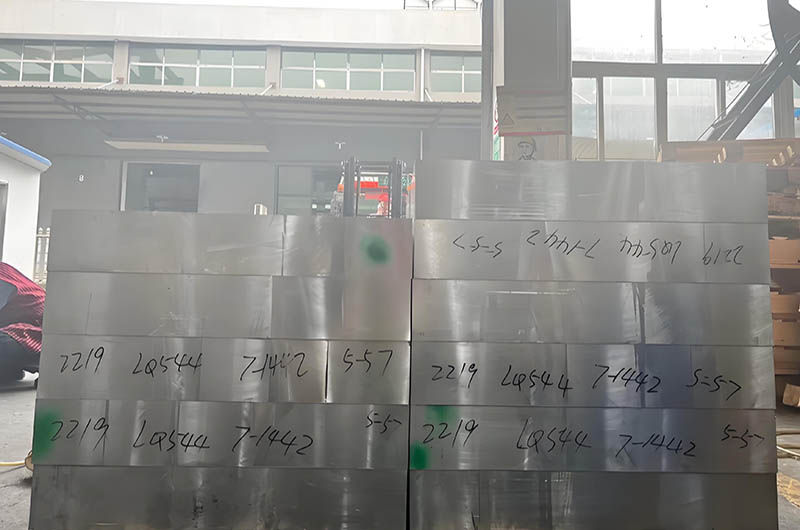

2219 T6 Aluminum

2219-T6 aluminum is a high-strength aluminum alloy, particularly suitable for aerospace and other high-stress, weight-critical applications.

- Series: Part of the 2xxx series (aluminum-copper alloy).

- Condition: T6 indicates that it has undergone solution heat treatment and artificial aging, optimizing strength and hardness.

2219-T6 Aluminum Alloy is a high-strength, age-hardened alloy in the aluminum-copper (2xxx) series. In the T6 condition, the alloy undergoes solution heat treatment followed by artificial aging to optimize its strength while maintaining reasonable ductility.

2219 T6 Aluminum Alloy Properties

- Weldability: Superior among 2xxx alloys; the strength after welding is about 60% (commonly used in fuel tanks and structural components).

- Corrosion Resistance: Moderate; 2219 T6 Aluminum Alloy generally requires coatings (anodizing, aluminum plating) or painting, especially in harsh environments.

- Low-Temperature Performance: Maintains performance at low temperatures, suitable for low-temperature storage (e.g., liquid oxygen tanks).

- Machinability: Good in annealed condition; due to high hardness, machining in T6 condition is more difficult.

2219 T6 Aluminum Alloy Standards and Specifications

- AMS: 4190 (Aerospace Material Specification).

- ASTM: B209 (Aluminum Sheet/Plate Standard Specification).

- SAE: J454 (Chemical Composition Standard).

2219 T6 Aluminum Alloy Composition

2219 aluminum alloy belongs to the aluminum-copper series, with high strength and good corrosion resistance, particularly suitable for high-temperature environments. It is commonly used in aerospace and industrial structures where high-temperature resistance, corrosion resistance, and good mechanical properties are required.

The basic composition of this alloy includes copper as the main alloying element, along with small amounts of manganese, silicon, and magnesium.

| Elements | Composition(%) |

| Si | ≤0.2 |

| Fe | ≤0.3 |

| Cu | 5.80-6.80 |

| Mn | 0.20-0.40 |

| Mg | ≤0.02 |

| Zn | ≤0.1 |

| Ti | 0.02-0.10 |

| V | 0.05-0.15 |

| Zn | 0.10-0.25 |

| Others | Each: 0.05 |

| Total: 0.15 | |

| Al | Bal |

T6 Temper 2219 Aluminum Heat Treatment Process

- Solution Heat Treatment: In the T6 condition, 2219 aluminum alloy is first heated to the solution temperature (usually between 495°C and 520°C) to completely dissolve the solute elements in the alloy, forming a homogeneous solid solution.

- Artificial Aging: Then, artificial aging is performed at a lower temperature (approximately 190°C to 210°C) to precipitate the solid solution in the alloy and enhance its strength. This process controls the size and distribution of the precipitate phase by adjusting the time and temperature to maximize strength.

2219 T6 Aluminum Alloy Applications

| Field | Application |

| Aerospace | Due to its excellent strength, fracture toughness, and high-temperature stability, 2219-T6 is widely used in aerospace applications such as external fuel tanks, fuselage/wing structures, and other high-stress, high-temperature environments. Examples include fuel tanks, structural components of spacecraft (such as the Space Shuttle and International Space Station), and other high-stress, high-temperature applications. |

| Industrial | In the industrial sector, 2219-T6 aluminum alloy is widely used in the manufacture of high-stress welded structures and low-temperature containers. Due to its excellent welding properties and strong low-temperature performance, 2219-T6 is suitable for structures that must endure high stress, such as pressure vessels, pipelines, and other industrial equipment in the oil and gas industry. Furthermore, the low-temperature toughness of 2219-T6 ensures its stability in low-temperature environments, making it an ideal material for liquefied gas storage containers and low-temperature pipelines, ensuring safety and durability in harsh conditions. |

2219 T6 Aluminum Welding and Machining Performance

- Weldability: Due to its high copper content, 2219-T6 aluminum has poor weldability. Hot cracking may occur during welding, so special care must be taken to use the appropriate welding methods and alloys to reduce the brittleness of the heat-affected zone during welding.

- Machinability: After solution heat treatment and artificial aging, 2219-T6 aluminum alloy has high hardness, which means it requires harder tools for machining. Cutting and drilling may require higher cutting forces.

2219 T6 Aluminum Corrosion Resistance

Corrosion Resistance: Although 2219-T6 aluminum has high strength, its corrosion resistance is lower compared to other aluminum alloys (such as 7050 or 6061 aluminum), particularly in chloride environments. Therefore, additional corrosion protection measures such as coatings or anodizing treatments should be considered in applications.

Corrosion Considerations:

While 2219 alloy has good mechanical properties, its inherent corrosion resistance is lower than some other aluminum alloys. To address this issue, it is often clad with pure aluminum or treated with protective coatings to extend its lifespan in corrosive environments.

2219-T6 Aluminum Alloy is a high-performance material where strength, toughness, and thermal stability are crucial. Its controlled chemical composition and precise heat treatment process produce a material that meets the demanding requirements of aerospace and other advanced engineering applications.

2219 T6 Aluminum Alloy vs Other Alloys

| Comparison | Detailed Description |

| Compared to 2024-T6 | 2219 T6 Aluminum Alloy has superior weldability and thermal stability compared to 2024 T6. Although 2024 T6 excels in riveted structures, suitable for applications requiring high strength and pressure, such as aircraft structures, it has poor weldability and may experience cracking during welding. In contrast, 2219 T6 performs better during welding, capable of withstanding stresses in high-temperature environments, and has stronger thermal stability, making it more suitable for structures requiring high-temperature welding. |

| Compared to the 7xxx Series | 2219 T6 Aluminum Alloy has lower strength compared to the 7xxx series (such as 7075), but offers better corrosion resistance and weldability. The 7075 series alloys have very high strength, making them ideal for high-strength aerospace components, but their corrosion resistance is poor, and they are difficult to weld. In contrast, 2219 T6, while slightly lower in strength than 7075, has better corrosion resistance, especially in humid or marine environments. Additionally, 2219 T6 has stronger welding properties, making it suitable for applications requiring higher welding process demands. |

2219 T6 Aluminum Alloy Processing and Manufacturing

- Heat Treatment: In the T6 condition, 2219 undergoes solution heat treatment (heating to dissolve alloying elements), followed by quenching and artificial aging. This process promotes the precipitation of strengthening phases, achieving high mechanical properties.

- Forming and Processing: Although 2219-T6 is typically not cast, it is usually processed through forging, extrusion, and machining. Its excellent weldability (with appropriate precautions) makes it the material of choice for applications where joining is critical.

- Weldability: Due to its high copper content, 2219-T6 has poor weldability. Thermal cracking may occur during welding, so special care must be taken with appropriate welding methods and alloys to reduce brittleness in the heat-affected zone during welding.

- Machinability: After solution heat treatment and artificial aging, 2219-T6 aluminum alloy has a high hardness, meaning it requires harder tools for machining. Cutting and drilling may require greater cutting forces.

2219 T62 Aluminum Advantages and Limitations

2219 T62 Aluminum Advantages

- High tensile strength and yield strength, suitable for environments with high stress and high load.

- Excellent high-temperature resistance, ideal for high-temperature operating environments.

- Good fatigue resistance, suitable for use in repetitive stress environments.

2219-T6 is a high-strength, weldable aluminum-copper alloy, highly regarded in the aerospace industry for its thermal stability and low-temperature performance. While it requires corrosion protection, its balanced performance makes it indispensable in critical structural applications.

2219 T62 Aluminum Limitations

- Due to its low ductility, it is not suitable for applications that require large deformations or complex shaping.

- Poor weldability, requiring additional process control.

- Relatively low corrosion resistance, suitable for use in low-corrosion environments.

- Requires corrosion protection.

- Lower fatigue strength compared to 7xxx alloys.

- Higher cost due to its specialized use in aerospace.

2219-T6 aluminum, as a high-strength aluminum alloy, is particularly suitable for applications in high-load, high-stress, and high-temperature environments, such as structural components and engine parts in the aerospace industry. However, its low ductility makes it unsuitable for applications that require complex shapes or large deformations.

2219 T6 Aluminum Mechanical Properties

| Property | 2219-T6 Aluminum |

| Elastic (Young's, Tensile) Modulus, GPa | 72 |

| Elongation at Break, % | 5.4 |

| Fatigue Strength, MPa | 110 |

| Poisson's Ratio | 0.33 |

| Shear Modulus, GPa | 27 |

| Shear Strength, MPa | 250 |

| Tensile Strength: Ultimate (UTS), MPa | 420 |

| Tensile Strength: Yield (Proof), MPa | 280 |