2219 T851 Aluminum

What is 2219 T851 Material?

2219-T851 is a high-performance aluminum alloy that has been specially heat-treated, suitable for demanding aerospace, military, and industrial applications, particularly in environments that require high strength and excellent corrosion resistance.

The 2219-T851 aluminum alloy is based on an aluminum-copper alloy system, and it undergoes a precise heat treatment process to enhance its mechanical properties.

2219 aluminum is a member of the 2xxx series, which is known for its high strength and excellent fracture toughness. In the T851 condition, the material undergoes solution heat treatment, cold working, followed by stress relief (typically through stretching) to enhance strength and dimensional stability. This makes it especially valuable in demanding aerospace applications.

- Lower corrosion resistance: Compared to 5xxx/6xxx alloys; requires protective coatings.

- Cost: Due to special processing, the cost is higher than that of standard alloys.

Features of 2219 T851 Aluminum

- High strength: 2219-T851 aluminum alloy has excellent strength, particularly suitable for high-strength, low-weight structural applications in aircraft and spacecraft.

- Good corrosion resistance: 2219 aluminum alloy has good corrosion resistance, making it ideal for use in harsh environments such as marine climates and outer space.

- Good weldability: Despite its high strength, 2219 aluminum alloy also has good weldability, making it suitable for manufacturing large welded components in aerospace.

- High-temperature resistance: Due to its higher copper content, 2219 aluminum alloy has good stability at high temperatures, making it suitable for use in high-temperature environments, such as liquid fuel rocket engine parts.

- Stress corrosion resistance: Good, especially under T8xx temper conditions.

- Machinability: Moderate; requires hard carbide tools for best results.

- Fatigue resistance: Maintains structural stability under repeated loads, suitable for dynamic stress environments.

- Processability: Exhibits good machinability, weldability, and formability, making it easy to process for further applications.

2219 T851 Aluminum Supplied Forms

Aluminum Alloy 2219 is available in a full range of sheet, plate, bar, wire and forgings.

| Product Name | Description |

| 2219 T851 Rolled Plate | A flat plate made from aluminum alloy 2219 in the T851 temper, suitable for applications requiring high strength, excellent fracture toughness, and corrosion resistance, especially in aerospace and military structural components. |

| Aluminium Alloy 2219 T851 Bar | Solid round or square bars made from 2219 aluminum alloy with high strength, commonly used for high-stress structural components in aerospace applications. |

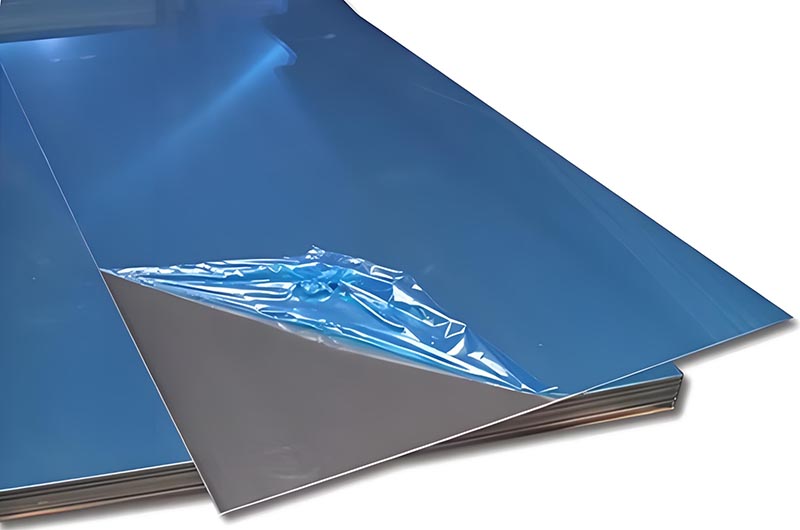

| Aluminium 2219 T851 Sheet / Plate (Bare) | Flat, thin sheets or plates of 2219 aluminum alloy in the T851 temper, with no protective coating, typically used in aerospace, military, and high-performance applications for structural integrity and strength. |

| 2219 T851 Drawn, Seamless Tubing | Seamless tubing made from 2219 aluminum alloy, with high strength and toughness, suitable for applications where strength and fatigue resistance are critical, such as fuel tanks and aerospace structures. |

| 2219 T851 Clad Sheet Plate | A sheet of 2219 aluminum alloy clad with a layer of aluminum alloy to enhance corrosion resistance, commonly used in aerospace applications to improve durability and resistance to environmental factors. |

| 2219 T851 Hand Forgings | Hand-forged products made from 2219 T851 aluminum, typically used for custom applications requiring high strength and specific shapes, such as aircraft components and other structural parts. |

| 2219 T851 Alclad Sheet | A sheet of 2219 T851 aluminum with a thin aluminum alloy cladding to improve corrosion resistance, commonly used in aerospace and military applications, emphasizing strength and corrosion resistance. |

| Aluminium Alloy 2219 T851 Extrusions | Shapes or profiles extruded from 2219 T851 aluminum alloy, allowing for the creation of custom profiles in the aerospace and military industries, with excellent strength and fatigue resistance. |

| Aluminum Flat Rolled Plate 2219 T851 Hot Rolled Mill Finish | Flat rolled plate or sheet of 2219 aluminum alloy, T851 temper, produced by hot rolling with a rough mill finish, typically used for structural aerospace and other high-performance applications. |

2219 T851 Aluminum Plate Standards and Specifications

- AMS 4117: Aerospace material specification for 2219-T851 plate/sheet.

- ASTM B209: Standard specification for aluminum alloy rolled products.

- MIL-A-8923: Military specification for aerospace applications.

- AMS-QQ-A-250/30 (for bare plate/sheet)

- AMS 4094 (for clad plate/sheet)

- ASTM and other international standards ensure the material meets quality, dimensional, and performance requirements.

2219 T851 Aluminum Chemical Composition Limits

| Weight% | Al | Si | Fe | Cu | Mn | Mg | Zn | Ti | Others | V | Zn |

| Alloy 2219 | Bal | 0.20 max | 0.30 max | 5.80-6.80 | 0.20-0.40 | 0.02 max | 0.10 max | 0.02-0.10 | 0.050 each 0.15 total | 0.05-0.15 | 0.10-0.25 |

2219 T851 Aluminum Typical Mechanical Properties

Aluminium Alloy 2219 - Bar / Extrusions

| Material | Temper | Direction | Tensile Strength ksi | Yield Strength ksi | Elongation in 2" (%) |

| Alloy 2219 (AMS 4162) | T8511 | L | 58 | 42 | 6 |

| Alloy 2219 (AMS 4162) | T8511 | LT | 56 | 39 | 4 |

Aluminium 2219 - Sheet / Plater (Bare)

| Material | Temper | Thickness | Tensile Strength ksi | Yield Strength ksi | Elongation in 2" (%) |

| Alloy 2219 (QQ-A-250/30) | 0 | 0.020"-2.00 | 32 max | 16 max | 12 |

| Alloy 2219 (QQ-A-250/30) | T351 | 0.250" - 2.00" | 46 | 28 | 10 |

| Alloy 2219 (QQ-A-250/30) | T851 | 0.250" - 2.00" | 62 | 46 | 7-8 |

Aluminium 2219 - Sheet / Plater (Clad) Temper T81 / T851

| Material | Temper | Thickness | Tensile Strength ksi | Yield Strength ksi | Elongation in 2" (%) |

| Alloy 2219 (AMS 4094) | T81/ T851 | 0.020"-0.039" | 49 | 37 | 6 |

| Alloy 2219 (AMS 4094) | T81/ T851 | 0.039"-0.099" | 55 | 41 | 7 |

| Alloy 2219 (AMS 4094) | T81/ T851 | 0.099"-0.249" | 58 | 43 | 7 |

| 2219 (AMS 4094) | T81/ T851 | 0.245"-0.499" | 58 | 42 | 8 |

Aluminum 2219-T851 Material Data Sheet

| Physical Properties | Metric | English | Comments |

| Density | 2.84 g/cc | 0.103 lb/in³ | AA; Typical |

| Mechanical Properties | |||

| Hardness, Brinell | 130 | 130 | 500 kg load with 10 mm ball |

| Hardness, Knoop | 163 | 163 | Converted from Brinell Hardness Value |

| Hardness, Rockwell A | 49.5 | 49.5 | Converted from Brinell Hardness Value |

| Hardness, Rockwell B | 80 | 80 | Converted from Brinell Hardness Value |

| Hardness, Vickers | 149 | 149 | Converted from Brinell Hardness Value |

| Ultimate Tensile Strength | 455 MPa | 66000 psi | AA; Typical |

| Tensile Yield Strength | 352 MPa | 51000 psi | AA; Typical |

| Elongation at Break | 10 % | 10 % | AA; Typical; 1/16 in. (1.6 mm) Thickness |

| Modulus of Elasticity | 73.1 GPa | 10600 ksi | AA; Typical; Average of tension and compression. Compression modulus is about 2% greater than tensile modulus. |

| Poisson's Ratio | 0.33 | 0.33 | Estimated from trends in similar Al alloys. |

| Fatigue Strength | 103 MPa | 15000 psi | AA; 500,000,000 cycles completely reversed stress; RR Moore machine/specimen |

| Shear Modulus | 27 GPa | 3920 ksi | Estimated from similar Al alloys. |

| Shear Strength | 285 MPa | 41300 psi | |

| Electrical Properties | |||

| Electrical Resistivity | 5.7e-006 ohm-cm | 5.7e-006 ohm-cm | |

| Thermal Properties | |||

| CTE, linear 68°F | 22.3 µm/m-°C | 12.4 µin/in-°F | AA; Typical; Average over 68-212°F range. |

| CTE, linear 250°C | 24.1 µm/m-°C | 13.4 µin/in-°F | Estimated from trends in similar Al alloys. 20-300°C. |

| Specific Heat Capacity | 0.864 J/g-°C | 0.207 BTU/lb-°F | |

| Thermal Conductivity | 120 W/m-K | 833 BTU-in/hr-ft²-°F | |

| Melting Point | 543 - 643 °C | 1010 - 1190 °F | AA; Typical range based on typical composition for wrought products 1/4 inch thickness or greater. Eutectic melting is not eliminated by homogenization. |

| Solidus | 543 °C | 1010 °F | AA; Typical |

| Liquidus | 643 °C | 1190 °F | AA; Typical |

| Processing Properties | |||

| Annealing Temperature | 413 °C | 775 °F | |

| Solution Temperature | 535 °C | 995 °F | |

| Aging Temperature | 163 - 191 °C | 325 - 375 °F | from 18 to 36 hr at temperature |

Applications of 2219 T851 Aluminum

| Domain | Application | Description |

| Aerospace | Aircraft fuselage skin, wing structure, fuel tanks, and other critical structural components | 2219 T851 aluminum plate is widely used in aerospace due to its excellent strength, high-temperature performance, and good corrosion resistance. It is especially useful in aircraft fuselage skins and wing structures, providing the necessary strength and lightweight properties to withstand pressure and temperature changes during high-altitude and high-speed flight. The manufacturing of fuel tanks also relies on 2219 aluminum plate, as its corrosion resistance and strength ensure safe and reliable storage and transmission of aviation fuel. In addition, other critical structural components such as landing gear frames and support structures are also made from 2219 T851 aluminum plate to provide the required strength and durability. |

| Military | Armor vehicle parts and missile components | 2219 T851 aluminum plate is used in the military sector to manufacture armor vehicle parts and missile components. The high strength and high-temperature performance of this aluminum plate improve impact resistance in armored vehicle protection structures, while maintaining a lighter weight for enhanced mobility. In missile component manufacturing, 2219 aluminum plate's high-temperature performance ensures stability under extreme thermal stress, guaranteeing reliable performance during missile launch and flight. |

| Industrial | High-stress fasteners and tools | 2219 T851 aluminum plate is used in industrial applications for manufacturing high-stress fasteners and tools. The high strength and rigidity of this aluminum plate make it ideal for fasteners and components that endure heavy loads or high-stress environments. During the manufacturing process, 2219 aluminum plate exhibits excellent resistance to deformation and fatigue, making it suitable for long-term repetitive load-bearing. In tool manufacturing, especially for tools requiring precise cutting and heavy-duty operations, 2219 T851 aluminum plate provides the necessary hardness and durability. |

| High-temperature applications | Strength and reliability under thermal stress are critical | 2219 T851 aluminum plate excels in high-temperature applications, especially in environments subject to thermal stress. It can maintain strength and dimensional stability at high temperatures, making it widely used in aircraft engine parts, rocket components, and other high-temperature operating structural parts. In these applications, the high-temperature strength and thermal fatigue resistance of 2219 aluminum plate allow it to withstand prolonged thermal stress, ensuring the safety and reliability of components under high-temperature conditions. This gives it a longer service life in high-temperature working conditions, especially in aerospace and military fields. |

Heat Treatment Process of 2219-T851 Aluminum

- Solution Heat Treatment: The first step involves heating the 2219 aluminum alloy to a specific temperature (typically between 520°C and 540°C). During this process, the alloying elements (such as copper) fully dissolve into the matrix, forming a uniform solid solution.

- Stress Relieving: To eliminate internal stresses generated during heat treatment, the metal is stretched by a certain amount. The amount of stretching depends on the type of forged product (such as thin sheets, plates, bars, or forgings). Stress relieving helps prevent deformation during subsequent processing.

- Artificial Aging: After completing the solution heat treatment and stress relieving, the material enters the artificial aging phase. This step typically involves heating the aluminum alloy to a lower temperature (about 160°C to 180°C) to promote the formation of precipitate hardening phases, further enhancing the strength and hardness of the aluminum alloy.

2219 T851 Aluminum Plate Processing and Manufacturing

- Form: Supplied in rolled plate form.

- Machinability: 2219-T851 is very suitable for conventional machining, drilling, milling, and turning.

- Weldability: Despite the challenges of welding copper-containing alloys, 2219 maintains good weldability as long as appropriate techniques and post-weld heat treatment are applied.

- Corrosion Considerations: The inherent copper content means this alloy is moderately sensitive to corrosion. To improve its corrosion resistance, it is typically coated with a thin layer of commercial pure aluminum (such as alloy 1050) or protected through surface coatings.

- Formability: Due to moderate formability, complex shapes require annealing.

- Stress Relief: Stretching (1-3% permanent strain) is used to minimize residual stresses.

2219-T851 aluminum plate has a unique combination of weldability, high-temperature performance, and strength, making it an indispensable material in aerospace and defense fields. Its T851 temper ensures stability for precision applications, but corrosion protection and proper processing maintenance are essential.