7475 T7351 Aluminum Plate Sheet

7475 T7351 aluminum plate refers to a specific grade of aluminum alloy that has undergone a particular heat treatment process, indicated by the "T7351" temper designation.

- Series: Part of the 7xxx series (aluminum-zinc-magnesium-copper alloys), known for its high strength.

- Composition: Main alloying elements are zinc (~5.6–6.4%), magnesium (~2.1–2.5%), copper (~1.2–1.9%), and chromium (~0.18–0.25%).

- Properties: Compared to similar alloys like 7075, it has enhanced fracture toughness and stress corrosion cracking (SCC) resistance due to stricter control of impurities (such as iron and silicon).

The T7351 condition of 7475 aluminum alloy is a high-strength, heat-treatable alloy primarily used in aerospace applications. This condition is achieved through specific heat treatment processes to enhance the alloy's mechanical properties.

T7: Solution heat treatment followed by aging (artificial aging) to stabilize the properties.

351:

- 3: Stress relief through mechanical stretching (1-3% permanent deformation).

- 51: Indicates stress relief of flat products (plates, thin plates) through stretching.

Advantages: Improves stress corrosion cracking (SCC) resistance and dimensional stability for machined parts.

7475 T7351 aluminum plate is a precision engineering material designed for applications requiring high strength, durability, and reliability. With the proper heat treatment and finishing to meet specific operational requirements, its properties make it a valuable component across various industries.

7475-T7351 aluminum alloy is a high-strength aluminum alloy, which belongs to the T7351 temper of the 7475 series. Its manufacturing process involves a series of complex heat treatment steps designed to optimize its properties, especially in terms of stress corrosion resistance.

7475 aluminum alloy is an aluminum alloy with zinc as the primary alloying element, typically containing magnesium, copper, chromium, and other elements. Its chemical composition provides high strength, making it suitable for applications requiring high strength and corrosion resistance, such as in aerospace. The T7351 temper of 7475 aluminum is enhanced through precise heat treatment to improve its stress corrosion resistance.

7475-T7351 aluminum alloy has various designations:

UNS A97475; ISO AlZn5.5MgCu(A); Aluminium 7475-T7351; AA7475-T7351; Al7475-T7351

T7351 7475 Aluminum Heat Treatment Process

The T7351 temper of 7475 aluminum is achieved through a series of heat treatment and mechanical processing steps. First, the aluminum alloy undergoes solution heat treatment to increase its strength. Next, a stress relieving process is performed, involving the stretching of the metal to reduce internal stresses and improve material stability. Finally, artificial aging is applied to further enhance the alloy's mechanical properties and stress corrosion resistance.

- Solution Heat Treatment: This process involves heating the 7475 aluminum alloy to a specific temperature, allowing the alloying elements to dissolve into the matrix, resulting in a uniform composition distribution.

- Stress Relieving: This step applies a certain degree of stretching to the 7475 aluminum alloy to remove internal stresses formed during casting or forging. It helps improve the alloy's subsequent processing performance and reduces deformation during use.

- Artificial Aging: This step involves controlling temperature and time to trigger precipitation reactions within the metal, stabilizing its properties. The degree and duration of aging will affect the alloy's final strength and corrosion resistance. In the T7351 temper, the aging process is specially designed to enhance stress corrosion resistance.

7475 T7351 Properties

- Fatigue Resistance: Excellent, suitable for cyclic load applications.

- Corrosion Resistance: Better SCC resistance compared to T6 temper; anodizing or coating is recommended for harsh environments.

- Strength: The strength of 7475-T7351 aluminum alloy is lower than other 7475 alloys but still offers satisfactory strength and stiffness, suitable for a variety of structural applications. Its yield strength and tensile strength perform well in meeting specific engineering requirements.

- Toughness: Compared to other high-strength aluminum alloys, 7475-T7351 may have slightly lower toughness, but with appropriate treatment, its toughness is sufficient for most applications.

7475 T7351 Fatigue Resistance

7475 T7351 aluminum alloy has exceptional fatigue resistance, making it suitable for applications subjected to long-term cyclic loads. The alloy’s microstructure and performance after specific heat treatment (T7351 condition) enable it to maintain excellent fatigue resistance under repeated loading conditions. Especially in high-demand fields like aerospace, 7475 T7351 can effectively resist alternating loads and vibrations during flight, helping to extend the service life of structural components and reduce damage caused by fatigue.

7475 T7351 Corrosion Resistance

7475 T7351 aluminum alloy exhibits superior resistance to stress corrosion cracking (SCC) compared to T6 temper. This makes 7475 T7351 more durable in harsh environmental conditions, especially in humid or salt-laden environments. To further enhance its corrosion resistance, it is recommended to apply anodizing or coating protection to the surface of structural components made from this alloy. These surface treatments help prevent corrosion, extend service life, and maintain structural integrity, particularly for components exposed to severe climatic conditions in marine or aerospace applications.

7475 T7351 Standards and Certifications

- AMS: AMS 4204 (sheet) and AMS 4205 (thin sheet).

- ASTM: B209 (Standard Specification for Aluminum and Aluminum Alloy Sheet and Plate).

- Military: MIL-DTL-46027 (for armor plate applications).

The product forms that Haomei Aluminum 7475 T7351 can provide

| Product Form | Image | Description |

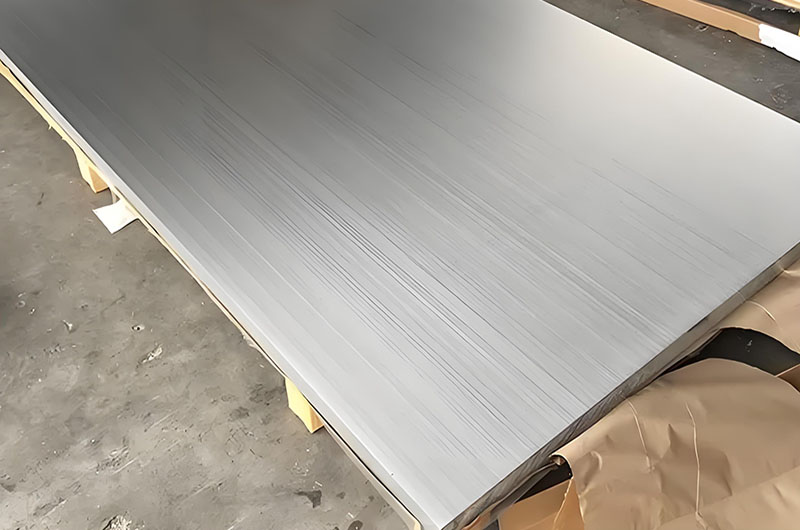

| Aluminum Sheet 7475 T7351 |

|

7475 T7351 aluminum sheet is a high-strength alloy commonly used in aerospace applications. Its excellent mechanical properties make it perform well in environments subjected to high stress and fatigue, suitable for large area cover components like aircraft fuselage skins and control surfaces. Due to its high strength, good corrosion resistance, and high-temperature resistance, 7475 T7351 aluminum sheet is widely used in aerospace structural parts that require high strength and reliability. |

| 7475 T7351 Rolled Plate |

|

7475 T7351 rolled plate has extremely high strength and fatigue resistance, widely used in critical aerospace structural components. It is commonly used in the manufacture of aircraft fuselage frames, wing beams, and other parts in high-stress areas. The rolling process makes its surface smoother, facilitating further processing and the forming of complex shapes, while offering good uniformity and thickness stability, making it suitable for parts that bear high loads. |

| 7475 T7351 Aluminum Forgings |

|

7475 T7351 aluminum forgings are typically used for manufacturing aerospace components that require high strength and impact resistance, such as engine parts, landing gear, and connectors. The forging process optimizes the internal structure of the 7475 T7351 aluminum alloy, providing excellent mechanical properties and higher material strength. Forgings can withstand high stress and extreme conditions, making them ideal for critical structural applications. |

| 7475 T7351 Aluminum Tubes |

|

7475 T7351 aluminum tubes are widely used in aerospace and military fields, particularly in piping systems and support structures. Its high strength and corrosion resistance make it suitable for use as hydraulic pipes, fuel pipes, and gas transmission pipes, as well as other components requiring high strength and long service life. Due to its good formability, 7475 T7351 aluminum tube is also commonly used in the manufacture of complex structures, offering lighter weight and excellent durability. |

| 7475 T7351 Aluminum Bars |

|

7475 T7351 aluminum bars are used to manufacture mechanical parts that require high strength and durability, especially in aerospace and military applications. The aluminum bar products are suitable for precision machining, such as connectors, support frames, and load-bearing components. Its high yield strength and good fatigue performance enable it to maintain stable performance under high loads and extended use conditions. |

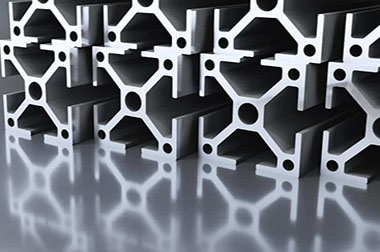

| 7475 T7351 Aluminum Profiles |

|

7475 T7351 aluminum profiles are widely used in aerospace and other high-performance industries. Through extrusion forming, 7475 T7351 aluminum profiles can provide customized cross-sectional shapes, suitable for fuselage frames, support structures, and load-bearing components. Its excellent mechanical properties and low density make it an ideal material for manufacturing complex shapes, able to withstand significant pressure and loads while maintaining a light weight. |

7475 T7351 Aluminum Applications

Due to its excellent strength-to-weight ratio, 7475-T7351 aluminum is widely used in the aerospace industry, including aircraft structural components, fuselage, wing beams, and more. It is also suitable for other high-performance engineering applications, such as high-strength frames and brackets.

- Aerospace Industry: Particularly for aircraft structural components that require relatively lower strength but excellent corrosion resistance, such as wing skins, fuselage frames, and landing gear components.

- Military Applications: Used in the manufacture of various high-performance aerospace and space equipment, especially in applications exposed to highly corrosive environments.

- High-strength Structural Components: Suitable for structural applications in ships, bridges, and other industrial fields.

7475 T7351 Advantages Over Similar Alloys

- Compared to 7075-T651, it has superior fracture toughness.

- Compared to T6 temper, it has better SCC resistance.

- Suitable for aerospace applications that require damage tolerance.

Superior Fracture Toughness Compared to 7075-T651

7475 T7351 aluminum alloy exhibits better fracture toughness than 7075-T651. While 7075-T651 has significant strength advantages, its fracture toughness is relatively weaker, making it prone to crack propagation in high-stress concentration areas. In contrast, 7475 T7351 significantly improves toughness through its unique heat treatment process (T7351 condition), particularly in resisting crack propagation and handling high-impact loads. Therefore, 7475 T7351 performs excellently in high-demand applications requiring enhanced fracture toughness, especially in aerospace, where preventing crack propagation and enhancing structural safety are crucial.

Better SCC Resistance Compared to T6 Temper

7475 T7351 aluminum alloy shows superior stress corrosion cracking (SCC) resistance compared to T6 temper alloys. In environments with high strength and complex loads, SCC is a major issue for aluminum alloys, and T6 temper alloys are prone to crack propagation under stress. By optimizing its alloy composition and heat treatment process, 7475 T7351 enhances its corrosion resistance, particularly in SCC performance. This makes 7475 T7351 more suitable for harsh environmental conditions, such as marine or high-humidity regions, effectively preventing cracks and corrosion damage caused by environmental factors.

7475 T7351 Aluminum Processing and Welding Properties

7475-T7351 aluminum alloy has good machinability and is suitable for common aluminum alloy processing methods such as extrusion, machining, and forging. However, due to its high-strength characteristics, special attention should be given to tool selection and processing conditions during machining. For welding, because of its high strength and the welding characteristics of aluminum alloys, specific welding techniques may be required to reduce the risk of cracks in the heat-affected zone.

7475 T7351 Aluminum Mechanical Properties

| Property | 7475-T7351 Aluminum |

| Elastic (Young's, Tensile) Modulus, GPa | 70 |

| Elongation at Break, % | 12 |

| Fatigue Strength, MPa | 190 |

| Poisson's Ratio | 0.32 |

| Shear Modulus, GPa | 26 |

| Shear Strength, MPa | 320 |

| Tensile Strength: Ultimate (UTS), MPa | 530 |

| Tensile Strength: Yield (Proof), MPa | 440 |

7475 T7351 Aluminum Thermal Properties

| Property | 7475-T7351 Aluminum |

| Latent Heat of Fusion, J/g | 380 |

| Maximum Temperature: Mechanical, °C | 180 |

| Melting Completion (Liquidus), °C | 640 |

| Melting Onset (Solidus), °C | 480 |

| Specific Heat Capacity, J/kg-K | 870 |

| Thermal Conductivity, W/m-K | 160 |

| Thermal Expansion, µm/m-K | 23 |

7475 T7351 Aluminum Electrical Properties

| Property | 7475-T7351 Aluminum |

| Electrical Conductivity: Equal Volume, % IACS | 42 |

| Electrical Conductivity: Equal Weight (Specific), % IACS | 120 |

7475 T7351 Aluminum Chemical Composition

| Chemical composition of 7475 alloy | |

| Si | 0.10 |

| Fe | 0.12 |

| Cu | 1.20-1.90 |

| Mn | 0.06 |

| Mg | 1.9-2.60 |

| Cr | 0.18-0.25 |

| Ni | - |

| Zn | 5.2-6.20 |

| Ti | 0.06 |

| Al | Remainder |

Hot Selling 7475 T7351 Aluminum Plate Size List

| Description | Thickness (t) |

| 7475-T7351 Aluminum Sheet | 0.5" |

| 7475-T7351 Aluminum Sheet | 0.75" |

| 7475-T7351 Aluminum Sheet | 1" |

| 7475 T7351 AMS4202 Aluminum Sheet | 1" |

| 7475-T7351 Aluminum Sheet | 1.25" |

| 7475-T7351 Aluminum Sheet | 1.5" |

| 7475-T7351 Aluminum Sheet | 1.75" |

| 7475 T7351 Aluminum Sheet | 1.75" |

| 7475-T7351 Aluminum Sheet | 2" |

| 7475-T7351 Aluminum Sheet | 2.25" |

| 7475-T7351 Aluminum Sheet | 2.5" |

| 7475-T7351 Aluminum Sheet | 2.75" |

| 7475-T7351 Aluminum Sheet | 3" |

| 7475-T7351 Aluminum Sheet | 3.25" |

| 7475-T7351 Aluminum Sheet | 3.5" |

| 7475-T7351 Aluminum Sheet | 4" |

Manufacturing Considerations

- Machining: High strength requires hard carbide tools; good machinability with proper techniques.

- Welding: Challenging due to heat cracking; friction stir welding (FSW) or special filler alloys (e.g., 4043) are recommended.

- Forming: Limited cold forming capability; hot forming is preferred.

While 7475-T7351 aluminum offers superior mechanical properties compared to other alloys, its high strength and alloy composition make welding difficult.

7475 T7351 Plate Treatment and Storage

- Store in dry conditions to prevent corrosion.

- Avoid contact with dissimilar metals to prevent galvanic corrosion.