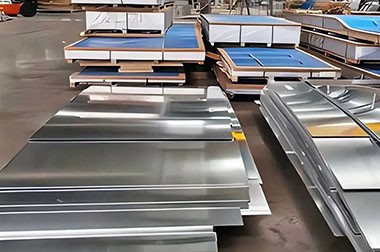

2004A Aerospace Aluminum Alclad Sheet Plate

2004 Aerospace Aluminum Alclad Plate is known for its excellent strength-to-weight ratio and good machinability. It typically exhibits high fatigue resistance and is commonly used in aerospace structures and components where weight reduction is critical. The aluminum cladding provides enhanced corrosion resistance, making it suitable for environments such as aircraft skins.

The 2024 aluminum plate is coated with a thin layer of pure aluminum to enhance its corrosion resistance and other properties, making it suitable for aerospace applications.

Cladding material: The outer layer is typically made of pure aluminum (usually 1100 or similar materials), which has excellent corrosion resistance.

Characteristics of 2004 Aerospace Aluminum Alclad Plate

- 1. Corrosion Resistance: The cladding protects the underlying alloy from environmental factors (such as moisture and salt) that could lead to corrosion.

- 2. Strength-to-Weight Ratio: Aerospace aluminum alloys are known for their high strength-to-weight ratio, which is crucial for improving fuel efficiency and performance in aerospace applications.

- 3. Formability: Aluminum clad plates can be easily formed into complex shapes, making them suitable for various components in aircraft.

- 4. Weldability: Depending on the alloy used, aluminum clad plates can exhibit good weldability, but care must be taken during welding to avoid issues related to the cladding layer.

Specifications of Haomei Aluminium alloy 2004 aerospace sheet plate

| Property | Details |

| Alloy | 2004 |

| Material Temper | F |

| Standards | AMS 4208, AMS 4209 |

| Thickness | 0.5 mm to 100 mm |

| Length | Customized (from a few centimeters to tens of meters) |

Manufacturing Process of 2004 Aerospace Aluminum Alclad Plate

- 1. Rolling: The base alloy is rolled to the desired thickness. The rolling process may involve hot working and cold working techniques.

- 2. Cladding: The cladding layer is applied using processes such as hot rolling or diffusion bonding. This ensures a strong bond between the cladding layer and the base alloy.

- 3. Heat Treatment: Certain alloys may undergo heat treatment to enhance their mechanical properties.

- 4. Finishing: The final product may undergo various finishing processes, such as anodizing or painting, to further enhance corrosion resistance and aesthetics.

Advantages of 2004 Aluminum Alclad Plate

- High strength-to-weight ratio, suitable for high-performance applications.

- Good machinability, making it suitable for various manufacturing processes.

Machinability of 2004 Aluminum Alclad Plate

- Welding: Caution is required when welding 2004 alloy, as welding is generally not recommended due to the potential reduction in strength.

- Forming: Can be processed through heat treatment, cold working, and other methods, making it suitable for manufacturing complex-shaped components.

Applications of 2004 Aerospace Aluminum Alclad Plate

1. Aerospace

Aircraft Structures: Used for fuselage skins, wings, and other critical components, emphasizing strength and lightweight design.

Spacecraft: Used in satellites and other aerospace vehicles that require high-performance lightweight materials.

2. Marine Applications

Due to its corrosion resistance, it is suitable for marine environments, especially for components exposed to saltwater.

3. Automotive and Transportation

Aluminum clad plates are used as lightweight structural components in high-performance vehicles to improve fuel efficiency and performance.

4. Military Applications

Used in aircraft wings, fuselage structures, and rocket components, where high strength and lightweight design are required.

5. Sports Equipment

Used in the manufacturing of high-performance sports equipment and motorcycle frames, enhancing performance and durability.

Chemical composition of Haomei 2004A aerospace aluminum alloy

| Element | Composition(%) |

| Si | 0.2 |

| Fe | 0.2 |

| Cu | 5.5-6.5 |

| Mn | 0.1 |

| Mg | 0.5 |

| Ti | 0.05 |

| Zr | 0.3-0.5 |

| Zn | 0.1 |

| Other (Each) | 0.0-0.05 |

| Aluminium (Al) | Balance |