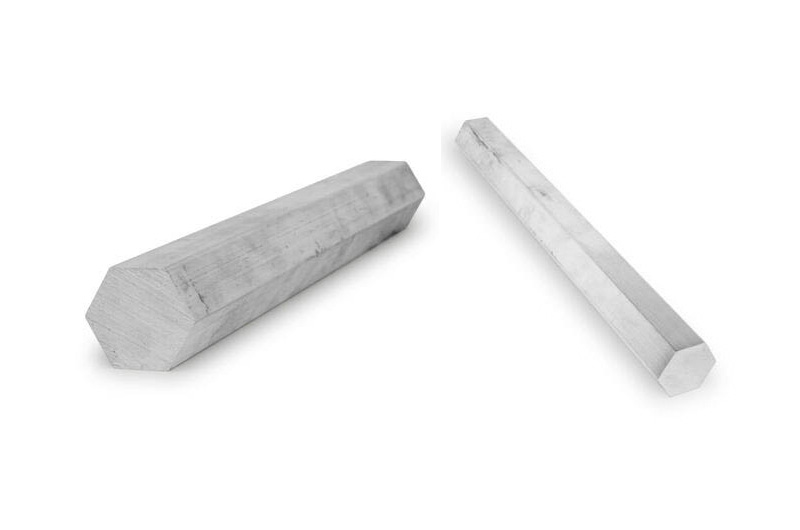

2011 Aluminum Hex Bar

2011 Aluminum Hex Bar is a widely used aluminum alloy product for the manufacturing of precision mechanical parts. It has a range of excellent machining properties and physical characteristics, making it an ideal material for high-precision machining.

2011 aluminum alloy belongs to the aluminum-copper alloy series and is commonly used in applications that require high strength and good machinability. It has excellent cutting performance and precise machining capabilities, making it ideal for manufacturing precision parts.

2011 Aluminum Hex Bar is an aluminum alloy with excellent machinability and moderate strength, making it particularly suitable for mechanical parts that require precision machining and high surface quality. Its non-magnetic nature and heat treatable characteristics make it widely used across various industries, especially in precision machinery and automation equipment.

2011 Aluminum Hex Bar Features

- High Machinability: 2011 aluminum alloy offers excellent machinability, being one of the easiest aluminum alloys to machine. Its cutting characteristics make it particularly suitable for automatic lathes, CNC machining, and other precision applications.

- Easy to Finish: In addition to standard machining, 2011 aluminum alloy is also highly suitable for precision operations such as turning, milling, and drilling.

- Non-Magnetic: 2011 aluminum alloy is a non-magnetic material, making it ideal for applications that require the avoidance of magnetic interference, such as electronic devices and medical equipment.

- Heat Treatable: Although it is typically supplied in T3 condition, 2011 aluminum alloy can still undergo heat treatment to improve its hardness and strength, meeting the requirements of various applications.

- High Strength: While it is slightly lower in strength compared to 7075 aluminum alloy, it still possesses sufficient strength for many mechanical and structural applications.

Popular 2011 Aluminum Hex Bar

- The T3 condition of 2011 aluminum alloy undergoes cold working and natural aging hardening, enhancing its strength and machinability, making it suitable for precision parts that require a balance of strength and machinability.

- The cold-worked surface forms a smooth appearance during the machining process, reducing surface roughness. This is suitable for applications where appearance is critical and also helps improve machining precision and wear resistance.

Hex 2011-T3 Aluminum

The T3 condition is a common delivery state for 2011 aluminum alloy, indicating that the alloy has undergone cold working followed by natural aging. Aluminum alloy in T3 condition exhibits higher strength and good machinability, making it suitable for many applications requiring a balance of strength and machinability.

| Feature | Description |

| Cold Working and Aging Treatment | Hex 2011-T3 Aluminum undergoes cold working (such as extrusion or stretching) followed by natural aging treatment, enhancing its strength and hardness. |

| Enhanced Strength | Hex 2011-T3 Aluminum typically has a tensile strength ranging from 310-400 MPa in the T3 condition, with increased hardness, meeting the strength requirements of lightweight structural components. |

| Good Machinability | Hex 2011-T3 Aluminum retains good machinability in the T3 condition, making it suitable for turning, milling, drilling, and other precision machining processes. |

| Versatility | Hex 2011-T3 Aluminum is suitable for applications in aerospace, precision machinery, automotive, and electronic components, offering good toughness and corrosion resistance. |

| Applications | Hex 2011-T3 Aluminum is commonly used in high-precision mechanical parts, structural supports, electronic devices, aerospace, and other fields. |

Aluminum Hex 2011-T3 Cold Finish

Cold finish refers to the smooth surface formed through cold working processes such as extrusion or rolling, without any additional heat treatment or surface treatment.

| Feature | Description |

| Smooth Surface | Aluminum Hex 2011-T3 Cold Finish has a smooth surface formed during the cold working process, reducing surface roughness, making it suitable for applications requiring high aesthetic quality. |

| No Additional Surface Treatment Needed | The cold finish surface of Aluminum Hex 2011-T3 naturally achieves a smooth effect, usually eliminating the need for additional surface treatments such as anodizing, painting, etc., thus saving costs. |

| Enhanced Machining Precision | Aluminum Hex 2011-T3 Cold Finish makes the surface finer, helping to improve machining accuracy, suitable for CNC machining, precision parts manufacturing, and other high-precision machining. |

| Wear Resistance | The smooth surface of Aluminum Hex 2011-T3 Cold Finish offers certain wear resistance, making it suitable for parts that experience high friction and frequent motion. |

| Applicable Fields | Aluminum Hex 2011-T3 Cold Finish is suitable for fields requiring good surface quality and precision, such as precision machinery, automotive parts, automation equipment, and electronic components. |

| Processing Method | Aluminum Hex 2011-T3 Cold Finish obtains its surface through cold working processes such as extrusion, rolling, and stretching, without involving high-temperature treatment, maintaining the original physical properties and chemical composition. |

2011 Aluminum Hex Bar Applications

- Precision Mechanical Parts: Due to its excellent machinability and non-magnetic properties, 2011 aluminum hex bar is widely used in the production of high-precision mechanical components, such as drive shafts, gears, bolts, and nuts.

- Automation Equipment: In automated production equipment, 2011 aluminum hex bars are commonly used to manufacture moving parts and supporting structures.

- Aerospace: Although not as strong as 7075 aluminum alloy, its light weight and machinability make it suitable for non-load-bearing components in the aerospace field.

- Electronic Components: Due to its non-magnetic properties, 2011 aluminum alloy is also commonly used in the manufacture of enclosures, connectors, and other electronic components.

- Automotive Parts: 2011 aluminum alloy is used in certain lightweight components in the automotive industry, such as engine components and brackets.

| Application Area | Detailed Description |

| Precision Mechanical Parts | 2011 Aluminum Hex Bar, due to its excellent machinability and non-magnetic properties, is widely used in the production of high-precision mechanical components. With its good strength and outstanding machinability, 2011 Aluminum Hex Bar is particularly suitable for manufacturing precision mechanical parts such as drive shafts, gears, bolts, and nuts. During the machining process, it easily meets complex machining requirements, fulfilling industrial applications with high precision and durability demands. |

| Automation Equipment | In automation production equipment, 2011 Aluminum Hex Bar is commonly used for manufacturing moving parts and support structures. Due to its good machinability and relatively light weight, 2011 Aluminum Hex Bar effectively reduces friction and load in mechanical motion, improving equipment efficiency and accuracy. It is suitable for components such as shafts, supports, and rails in various automation equipment, helping to enhance the performance and reliability of automated production lines. |

| Aerospace | Although 2011 Aluminum Hex Bar has lower strength compared to 7075 aluminum alloy, its excellent light weight and machinability make it widely used in non-load-bearing parts in the aerospace field. 2011 Aluminum Hex Bar is typically used to manufacture external parts of aircraft, cabin components, and other non-structural components in aerospace. Its outstanding machinability makes the production of these parts more efficient, while reducing overall weight, contributing to improved fuel efficiency and operational performance of aircraft. |

| Electronic Components | Due to its non-magnetic properties and excellent machinability, 2011 Aluminum Hex Bar is also commonly used to manufacture enclosures, connectors, and other precision parts for electronic components. 2011 Aluminum Hex Bar is widely used in the electronics industry, especially for manufacturing enclosures and connection components that require magnetic shielding. Its good thermal conductivity and corrosion resistance make it an ideal material choice for electronic devices, particularly in high-precision and high-reliability applications. |

| Automotive Parts | In the automotive field, 2011 Aluminum Hex Bar is mainly used to manufacture lightweight components, such as engine parts, brackets, and other structural components. The high machinability and lightweight characteristics of 2011 Aluminum Hex Bar make it an ideal choice for some key components in the automotive industry. By using this aluminum alloy, automobile manufacturers can effectively reduce vehicle weight, improve fuel efficiency, while maintaining sufficient strength and durability to meet the high standards of automotive components. |

2011 Aluminum Hex Bar Sizes and Specifications

Full Size and Custom Cutting: 2011 Aluminum Hex Bar is typically available in standard full-length sizes, or custom-cut lengths can be provided according to customer requirements to suit different machining needs.