2014 O T4 T6 T351 Aerospace Aluminum Sheet Plate

What is 2014 grade aluminium?

2014 aluminum plate is a high-strength, precipitation-hardened alloy belonging to the 2000 series aluminum alloys. It is renowned for its excellent machining characteristics and high-temperature performance, making it widely used in industries where strength and durability are crucial, particularly in aerospace, military, and automotive applications.

Due to the relatively poor corrosion resistance of 2014 aluminum, this alloy is often provided in a clad form (surface covered with pure aluminum) or undergoes surface treatments (such as painting) to prevent corrosion.

2014 aluminum alloy (2014A) contains 3.9% to 5% copper, offering excellent strength and good machinability. Due to its high strength, 2014 aluminum alloy is widely used in aircraft structures, military vehicles, bridges, weapons manufacturing, and other structural components requiring high strength and hardness.

2014 aluminum plate is the second most popular alloy in this series and is mainly processed through extrusion and forging techniques. This alloy also has good machinability, making it suitable for manufacturing molds, heavy machinery parts, wheels, truck frames, and suspension system components. The standard specifications for 2014 aluminum alloy include ASTM B209 and UNS A92014.

Although 2014 aluminum alloy has good machinability, its cold formability and weldability are relatively poor after full heat treatment.

Specifications of Haomei Aluminium Alloy 2014 aerospace sheet plate

Haomei Aluminum offers a variety of sizes and tempers (including T6, T651, or T652 temper) of 2014A aluminum plate in stock. Customized sizes of 2014 aluminum forged products, plates, and more can be supplied according to your specifications. Our forging processes include open-die forging, ring rolling, and more.

2014 Aluminum Temper

| Alloy Temper | Characteristics | Applications | Surface |

| 2014 O | Softened by full annealing for maximum formability | Sheet, plate, and parts requiring high formability | Bare or Clad |

| 2014 T3 | Solution heat-treated and cold worked for increased strength | Aircraft wing spars, structural components | Bare or Clad |

| 2014 T4 | Solution heat-treated and naturally aged for moderate strength | Aerospace parts, high-strength components | Bare or Clad |

| 2014 T6 | Solution heat-treated and artificially aged for high strength | Aerospace structures, heavy-duty components | Bare or Clad |

| 2014 T81 | Cold worked, solution heat-treated, and aged for high strength | Aircraft components under high stress | Bare or Clad |

| 2014 T351 | Solution heat-treated and stress-relieved by stretching | Aerospace components requiring high strength and stability | Bare or Clad |

| 2014 T851 | Solution heat-treated, stress-relieved by stretching, and aged | High-performance aerospace components | Bare or Clad |

| 2014 T74 | Solution heat-treated, stabilized, and aged | Aerospace applications requiring long-term stress resistance | Bare or Clad |

2014 Aluminum Standard Specifications

- ASTM B209

- ASTM B210

- ASTM B211

- ASTM B221

- ASTM B241

- ASTM B247

- ASTM BB241

- DIN 3.1255

- MIL T-15089

- QQ A-200/2

- QQ A-225/4

- QQ A-250/4

- QQ A-367

- SAE J454

- UNS A92014

2014 Aluminum Product Forms

| Product | Image | Description |

| 2014 Aluminum Forgings |

|

2014 aluminum forgings are typically used in high-stress applications due to their excellent strength and fatigue resistance. These forgings are produced through a controlled process that involves shaping the aluminum at high temperatures, making them ideal for critical components in aerospace and military industries. They exhibit a good combination of strength, machinability, and resistance to corrosion. |

| 2014 Aluminum Round Bar |

|

2014 aluminum round bars are highly regarded for their excellent machinability and strength. These bars are commonly used in aerospace, automotive, and structural applications where high-performance strength is required. They offer superior resistance to stress and are ideal for manufacturing components that must withstand intense operational environments. |

| 2014 Aluminum Flat Bar |

|

2014 aluminum flat bars are used in applications requiring moderate strength and formability. The flat bar shape makes it a versatile choice for fabricating a variety of structural and mechanical components. It is commonly used in aerospace, automotive, and other high-strength industries, offering good machinability and a high strength-to-weight ratio. |

| 2014 Aluminum Rectangular Bar |

|

2014 aluminum rectangular bars are often chosen for structural applications where strength and durability are crucial. Their shape allows for easy installation and precision machining, making them suitable for industries such as aerospace, military, and heavy equipment manufacturing. These bars are known for their high strength and corrosion resistance. |

| 2014 Aluminum Rolled Rings |

|

2014 aluminum rolled rings are used in high-performance applications that demand strength, toughness, and wear resistance. The rolling process shapes aluminum into ring-like forms, which are often utilized in aircraft, aerospace, and military sectors for components such as seals, flanges, and bushings. They provide excellent durability under mechanical stress. |

| 2014 Aluminum Forged Rings |

|

2014 aluminum forged rings are produced through a process that involves compressing aluminum billets into ring shapes under high pressure. These rings are typically used in heavy-duty applications such as aerospace engines, automotive parts, and military equipment, providing exceptional strength, resistance to fatigue, and high-performance reliability. |

| 2014 Aluminum Disc |

|

2014 aluminum discs are primarily used for manufacturing parts that require a circular shape and high strength, such as in aerospace, military, and manufacturing applications. These discs are highly machinable, offering good wear resistance and a high strength-to-weight ratio, making them suitable for critical components subject to high stress. |

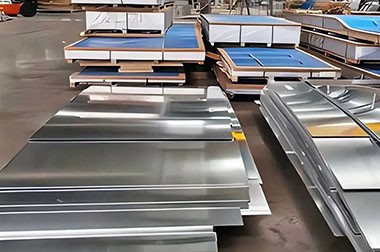

| 2014 Aluminum Sheet |

|

2014 aluminum sheets are lightweight, yet they offer impressive strength and formability. These sheets are widely used in the aerospace industry for parts that require both strength and ease of fabrication. They offer excellent weldability and corrosion resistance, making them ideal for structural components in challenging environments. |

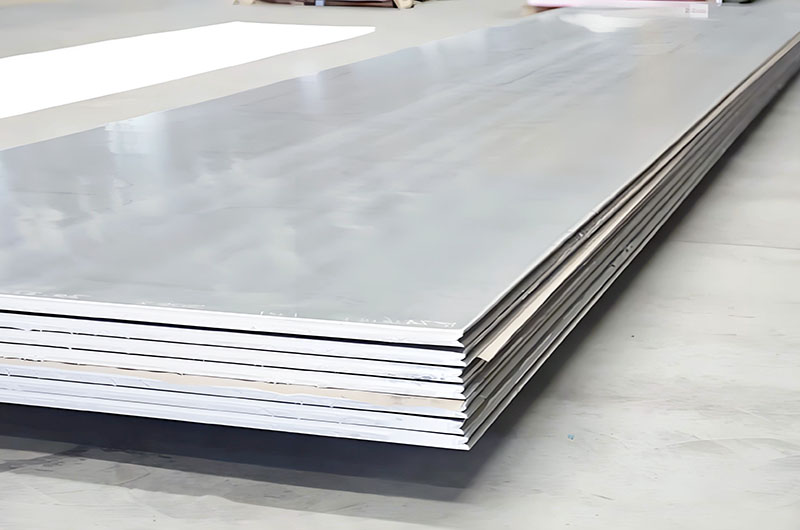

| 2014 Aluminum Plate |

|

2014 aluminum plates are known for their exceptional strength and are typically used in heavy-duty applications such as aerospace structures, military equipment, and transportation industries. They are available in thicker gauges and provide excellent machinability, making them suitable for creating high-stress components that require long-term durability. |

| 2014 Aluminum Extrusion |

|

2014 aluminum extrusions are highly versatile and are used in a wide range of applications, especially in the aerospace and automotive sectors. These extrusions allow for the creation of complex shapes while maintaining high strength and low weight. They offer good formability and can be tailored to specific application requirements. |

| 2014 Aluminum Extrusion Angles |

|

2014 aluminum extrusion angles are widely used in structural and framing applications, especially in industries like aerospace and construction. These angles are lightweight yet strong, providing excellent resistance to corrosion and fatigue. The extrusion process ensures precise shapes that meet the exact needs of various engineering designs. |

Characteristics of 2014 Aerospace Aluminum Plate

- High strength-to-weight ratio: 2014 aluminum is ideal for aerospace/structural applications.

- Heat treatable: Can be strengthened through T6 (solution heat treatment + artificial aging) or T651 (stress relief).

- Weldability: Poor; prone to cracking (use TIG/MIG with filler 4043/4145).

- Sensitivity: Prone to stress corrosion cracking in thick sections; avoid unprotected use in marine environments.

- High mechanical strength: 2014 aluminum alloy possesses excellent strength properties, maintaining stable performance under high loads. It is widely used in aircraft structural parts and fuselage frames, where high tensile and yield strength are required to meet stringent engineering demands.

- Excellent fatigue resistance: 2014 alloy has good fatigue performance, capable of withstanding prolonged cyclic loads without fatigue failure. This characteristic is crucial for aircraft, which endure repeated stress during flight, helping extend the service life of structural components.

- Superior machinability: 2014 aluminum alloy exhibits good performance during machining and can be effectively shaped using common machining methods such as cutting, milling, and welding. This makes it efficient for manufacturing complex shapes and precision components while ensuring excellent surface quality.

- Requires protective coating to prevent corrosion: While 2014 aluminum alloy has high strength and good machinability, its corrosion resistance is relatively poor. In humid environments or corrosive media, aluminum alloys are prone to oxidation and corrosion. Therefore, it is usually necessary to apply protective coatings (such as anodizing, spraying, or painting) to enhance its corrosion resistance, ensuring reliability and durability in harsh environments.

Chemical composition of 2014A aerospace aluminum alloy

| Element | Composition(%) |

| Si | 0.15-0.9 |

| Fe | 0.7 |

| Cu | 3.9-5.0 |

| Mn | 0.40-1.2 |

| Mg | 0.20-0.8 |

| Ti | 0.15 |

| Cr | 0.10 |

| Zn | 0.25 |

| Other (Each) | 0.0-0.05 |

| Aluminium (Al) | Balance |

Mechanical properties of 2014 aerospace high quality sheet plate

| Material | Temper | Thickness (mm) | Tensile strength min (N/mm2) | Yield Strength min (N/mm2) | Elongation in 50 mm | ||||

| 0.5 mm | 0.8 mm | 1.3 mm | 2.6 mm | 3.0 mm | |||||

| Alloy 2014 Sheet | T4 Bare | 0.2-6.0 | 400 | 225 | 13 | 14 | 14 | 14 | 14 |

| Alloy 2014 Sheet | T6 Bare | 0.2-6.0 | 440 | 380 | 6 | 6 | 7 | 7 | 8 |

| Alloy 2014 Sheet | T4 Clad | 0.2-1.6 | 385 | 240 | 13 | 14 | 14 | - | - |

| Alloy 2014 Sheet | T4 Clad | 1.6-6.0 | 395 | 245 | - | - | - | 14 | 14 |

| Alloy 2014 Sheet | T6 Clad | 0.2-1.6 | 420 | 345 | 7 | 7 | 8 | - | - |

| Alloy 2014 Sheet | T6 Clad | 1.6-6.0 | 420 | 355 | - | - | - | 9 | 9 |

Popular Aerospace Aluminum Plate 2014

2014 T4 Aluminum Sheet Plate

2014 T4 aluminum alloy is a heat-treated alloy with good strength and hardness, typically aged at room temperature. Its ductility is relatively low, making it suitable for applications requiring high strength.

Aerospace Application: In the aerospace industry, 2014 T4 aluminum alloy is commonly used to manufacture structural components such as wing and fuselage frames, as its combination of strength and toughness is ideal for environments subjected to high loads and stresses.

2014 T351 Aluminum Sheet Plate

2014 T351 aluminum alloy is a heat-treated and cold-worked aluminum plate, offering higher strength and good machinability. The T351 temper typically means the alloy has been stretched after heat treatment to improve its mechanical properties.

Aerospace Application: In aerospace, 2014 T351 aluminum alloy is often used in manufacturing structural components such as fuselages, wing spars, and other load-bearing parts due to its superior tensile strength and fatigue resistance.

2014 T851 Aluminum Sheet Plate

2014 T851 aluminum alloy is heat-treated and stretched, offering extremely high strength and excellent fatigue resistance. The T851 temper generally provides better stability and uniformity.

Aerospace Application: 2014 T851 aluminum alloy is widely used in high-performance structural components in the aerospace industry, such as aircraft wings and fuselage components, especially in environments where high pressure and high temperatures are encountered.

2014 T6 Alum Alclad

2014 T6 aluminum alloy is heat-treated to enhance its strength and surface-coated with aluminum (Alclad) for better corrosion resistance. The T6 temper indicates that the aluminum alloy has undergone full aging treatment.

Aerospace Application: In the aerospace field, 2014 T6 Alclad aluminum alloy is commonly used to manufacture external structural components such as fuselage skins and wing surfaces due to its excellent strength, corrosion resistance, and lightweight properties, making it ideal for high-performance aircraft designs.

Comparison of 2014 Aluminum with Other Alloys

- Compared to 2024: Similar strength; 2014 offers better machinability.

- Compared to 7075: Lower strength than zinc-based 7075 but better toughness.

- Compared to 6061: Lower corrosion resistance but higher strength.

The table below provides a detailed comparison of the performance differences between 2014 aluminum alloy and 2024, 7075, and 6061 aluminum alloys:

| Comparison Item | 2014 vs 2024 | 2014 vs 7075 | 2014 vs 6061 |

| Strength | The strength of 2014 aluminum alloy is similar to that of 2024 aluminum alloy, both being high-strength alloys suitable for aerospace applications. | The strength of 2014 aluminum alloy is lower than that of 7075 aluminum alloy, which has higher yield and tensile strength due to its zinc composition. | The strength of 2014 aluminum alloy is higher than that of 6061 aluminum alloy, making it suitable for high-stress structural components. |

| Machinability | 2014 aluminum alloy has better machinability than 2024 aluminum alloy, allowing for finer machining and cutting, making it suitable for manufacturing complex structures. | 2014 aluminum alloy has good machinability, whereas 7075 aluminum alloy is harder and thus more difficult to machine. | The machinability of 2014 aluminum alloy is slightly lower than that of 6061, but it still allows for good cutting and machining processes. |

| Corrosion Resistance | Both 2014 and 2024 aluminum alloys have poor corrosion resistance and require protective coatings or anodizing treatments. | The corrosion resistance of 2014 aluminum alloy is better than that of 7075 aluminum alloy, but it still requires additional protective measures to resist corrosion. | The corrosion resistance of 2014 aluminum alloy is far lower than that of 6061 aluminum alloy, which contains magnesium and silicon for improved corrosion resistance. |

| Toughness | The toughness of 2014 and 2024 aluminum alloys is similar, both being relatively low-toughness materials that are prone to cracking under high-stress conditions. | 2014 aluminum alloy has better toughness than 7075 aluminum alloy, making it advantageous in applications requiring some degree of deformation capability. | 2014 aluminum alloy has lower toughness than 6061 aluminum alloy, as 6061 provides better ductility and impact resistance. |

| Main Applications | Both 2014 and 2024 aluminum alloys are widely used in aircraft structural components, aerospace engine parts, and automotive components requiring high strength. | 2014 aluminum alloy is suitable for applications requiring high strength but not as extreme as 7075, such as aerospace components and mold manufacturing. | 2014 aluminum alloy is used in high-strength load-bearing structures, whereas 6061, due to its balanced properties, is commonly used in construction, marine applications, and general machinery manufacturing. |

2014 aluminum plate excels in high-strength and lightweight applications, particularly in the aerospace and defense industries. Through protective treatment, its limitations in corrosion resistance can be mitigated, making it a strategic choice where mechanical performance is crucial.

Applications of 2014 Aerospace Aluminum Plate

Aerospace: Due to its excellent strength-to-weight ratio, 2014 aluminum plate is widely used in aircraft structural components, fuselage, wing beams, and other areas.

- Aerospace structural components

- Aircraft fuselage and wings

- Aerospace engine components

- High-load mechanical components

| Application Area | Specific Applications | Advantages |

| Aerospace Structures | 2014 aluminum alloy is widely used in the aerospace industry due to its excellent strength-to-weight ratio, making it suitable for load-bearing structural components. | Excellent strength-to-weight ratio, suitable for applications that endure high stress and loads. |

| Aircraft Fuselage and Wings | 2014 aluminum alloy is used in aircraft fuselage frames, wing spars, and wing skins. It is primarily used for load-bearing parts of aircraft to ensure performance and safety. | High strength and fatigue resistance, suitable for aerospace structures, providing necessary strength while reducing weight. |

| Aerospace Engine Components | 2014 aluminum alloy is used in manufacturing key aerospace engine components, such as compressor blades and turbine casings, designed for high-temperature and high-stress environments. | High strength, heat resistance, and excellent fatigue resistance, making it ideal for engine components under high-load and high-temperature conditions. |

| High-Load Mechanical Parts | Used for critical load-bearing components such as landing gear, engine mounts, and structural supports, designed to endure heavy loads and impacts. | High strength and superior fatigue resistance, suitable for high-load and high-impact applications. |

Due to its excellent mechanical properties, 2014 aluminum plate is also used in:

- Automotive and truck manufacturing: Used for frames, suspension components, and high-strength machinery parts.

- Military and defense: Applied in vehicle armor, structural components, and areas requiring durable materials that can withstand high temperatures and mechanical stress.

- Industrial and mold manufacturing: Due to its excellent machinability and heat-treatable properties, it is suitable for high-stress mechanical parts, hydraulic components, precision parts, and heavy forgings.

- Transportation: Heavy forgings and suspension systems.

2014 Aluminum Plate Temper Designations and Processing

2014 aluminum plate is available in multiple tempers, including:

- O (annealed): Soft and highly ductile.

- T3 and T4: Intermediate conditions that balance strength and formability.

- T6/T651: These are solution heat-treated and artificially aged (T651 also undergoes stress-relief treatment), offering high strength and hardness, making them highly suitable for structural applications.

The manufacturing process typically involves hot rolling, with 2014 aluminum plates produced in thicknesses ranging from a few millimeters to several hundred millimeters. The width also varies, usually up to 2650 mm. The final products can be delivered with various surface finishes (rolled, polished, etc.), often protected with film or paper during transportation.

2014 Aluminum Plate Advantages and Limitations

Advantages of 2014 Aluminum Plate

| Advantage | Description |

| High Strength | 2014 aluminum plate possesses excellent strength characteristics, making it highly suitable for structural applications that require high load-bearing capacity. Due to its primary alloying element being copper, 2014 aluminum plate can achieve extremely high tensile and yield strength after proper heat treatment, making it widely used in aerospace, automotive, and high-stress mechanical components. |

| Machinability | 2014 aluminum plate exhibits excellent machinability, enabling precision machining, turning, milling, and drilling. Compared to other high-strength aluminum alloys, 2014 aluminum plate offers better cutting performance, making it particularly advantageous in industrial manufacturing and mold processing where high-precision components are required. |

| Heat Treatability | 2014 aluminum plate can undergo various heat treatment processes (such as T4, T6, T651, etc.) to adjust its mechanical properties, meeting the needs of different applications. Through appropriate heat treatment, 2014 aluminum plate can achieve a good balance between strength, hardness, and toughness, making it suitable for a wide range of high-performance engineering structures. |

| Lightweight | The density of 2014 aluminum plate is significantly lower than many conventional steel materials while maintaining an excellent strength-to-weight ratio. This property makes it an ideal material for applications that require weight reduction while maintaining high strength, such as aerospace components, racing structures, and high-performance machinery manufacturing, helping to improve fuel efficiency and overall performance. |

Limitations of 2014 Aluminum Plate

- Corrosion Sensitivity: Requires surface treatment or cladding to prevent corrosion.

- Welding Challenges: Prone to cracking during welding and usually requires specialized techniques.

2014 Aluminum Plate Manufacturing and Processing

- Machining: Produces fine chips; use sharp tools.

- Forming: Cold working requires annealing.

- Heat Treatment: Solution treatment (~500°C), quenching, aging (~160°C).

- Surface Treatment: Anodizing (Type II/III available, but with darker coloration), painting, or powder coating.

What is the equivalent of 2014A Aluminium?

| Country/Standard System | Equivalent Aluminum Alloy Name | Standard Number/Naming |

| United States (ASTM / UNS) | 2014 | UNS A92014 |

| Europe (EN) | EN AW-2014A | EN 573-3 |

| Germany (DIN) | AlCu4SiMg | DIN 1725 |

| United Kingdom (BS) | 2014A | BS L168 |

| France (AFNOR) | 2014A | NF A57-702 |

| International (ISO) | AlCu4SiMg | ISO 209-1:1989 |

Haomei Aluminum offers a wide range of aluminum sheet and plate specifications for aircraft. We supply AMS 4041, AMS 4041, AMS 4037, AMS 4035, AMS 4049, AMS 4050, AMS 4048, AMS 4045, AMS 4044, AMS 4027, AMS 4026, AMS 4025, AMS 4347, and AMS 4202. In addition, we also provide other alloys such as 2219, 2124, 7175, 7475, 2024, 7075 T73, and 7075 T76.