2024 Aerospace Aluminum Forging

What are 2024 Aluminum Forgings?

2024 aluminum alloy is one of the most popular high-strength materials in the forging industry. Known for its excellent fatigue resistance, high strength-to-weight ratio, and superior machinability, 2024 aluminum is ideal for applications requiring durability and reliability.

In the aerospace industry, 2024 aluminum forgings are crucial structural materials due to their lightweight and high-strength characteristics. Aircraft manufacturers widely use 2024 aluminum alloy, particularly in key components such as fuselage frames, wing ribs, and landing gear. These parts must have good strength and rigidity to withstand various forces and pressures during flight.

The aerospace sector also chooses forged 2024 aluminum alloy for its outstanding fatigue resistance, especially in structural components that must endure repeated loads.

Haomei Aluminum provides aerospace-grade 2024 aluminum forgings that meet the stringent standards required for aviation applications. Our 2024 aluminum forgings are produced with precision, ensuring they meet the demanding requirements of various industries.

Chemical Composition Of Aluminium Alloys 2024

| Element | Weight% |

| Al | 93.50 |

| Cu | 4.4 |

| Mn | 0.6 |

| Mg | 1.5 |

Mechanical Properties Of Aluminium Alloy 2024

| Properties | Conditions | ||

| T (°C) | Treatment | ||

| Density (×1000 kg/m3) | 2.77 | 25 | |

| Poisson's Ratio | 0.33 | 25 | |

| Elastic Modulus (GPa) | 70-80 | 25 | |

| Tensile Strength (Mpa) | 185 | 25 | O more |

| Yield Strength (Mpa) | 76 | ||

| Elongation (%) | 20 | ||

| Reduction in Area (%) | |||

| Hardness (HB500) | 47 | 25 | O more |

| Shear Strength (MPa) | 125 | 25 | O more |

| Fatigue Strength (MPa) | 90 | 25 | O more |

2024 Aerospace Aluminum Forging Applications

In the aerospace industry, 2024 aluminum forgings have become critical components due to their lightweight and high-strength properties. Aircraft manufacturers rely on 2024 aluminum to construct structural components such as fuselage frames, wing ribs, and landing gear. The material's excellent fatigue resistance ensures that aircraft can withstand the stresses of flight operations, providing safety and reliability.

- 1. In fuselage frame design, 2024 aluminum alloy offers engineers a lighter structural solution with its superior high-strength characteristics. This design not only effectively reduces the overall weight of the aircraft but also significantly improves fuel efficiency. Implementing lightweight designs allows aircraft to greatly decrease aerodynamic drag during flight, resulting in longer ranges and greater payload capacities. This is crucial for the economy and practicality of modern aircraft.

- 2. In the application of wing ribs, 2024 aluminum alloy provides the necessary support to ensure stability and strength of the wings under various flight conditions. Its outstanding material properties allow the wings to perform well in both high and low temperature conditions, which is vital for the safety of the aircraft in different climates and flying environments. Additionally, 2024 aluminum alloy has excellent welding and machining capabilities, enabling engineers to create complex geometries that meet the increasingly stringent structural requirements of modern aircraft design. This flexibility allows for more innovative aircraft designs to meet diverse mission and usage needs.

- 3. In the design of landing gear systems, the high strength and toughness of 2024 aluminum alloy are key factors in ensuring safe landings. Landing gear must endure significant impact forces during touchdown, which places high demands on material performance. With its exceptional physical properties, 2024 aluminum alloy can effectively absorb impact forces, reducing damage to the airframe and ensuring the safety of passengers and crew. Moreover, the lightweight design of the landing gear can also improve overall aircraft performance and reduce energy consumption during landing, further enhancing the economic benefits of the aircraft.

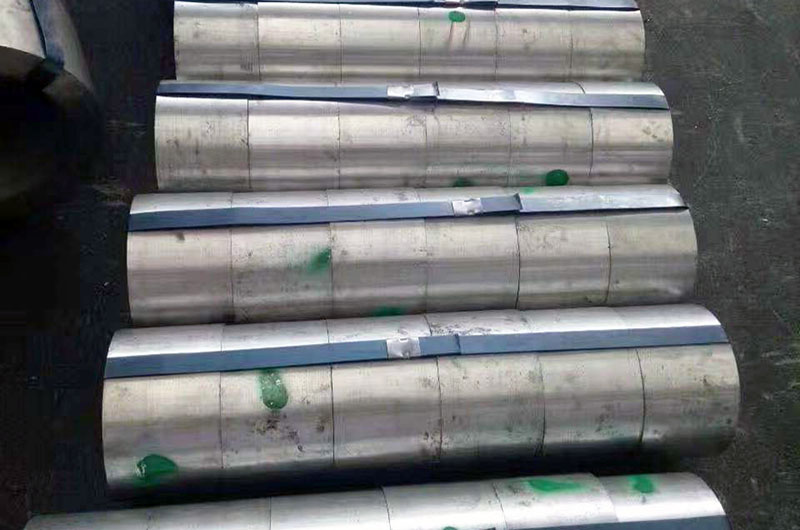

Forged 2024 aluminum alloy forms

| Aluminium Alloy 2024 Forged Fittings | Aluminium Alloy 2024 Forged Round Bars |

| Aluminium Alloy 2024 Forged Hex Bars | Aluminium Alloy AISI 2024 Forged Elbow |

| AISI 2024 Aluminium Alloy Forged Flanges | Aluminium Alloy 2024 Forged Stubends |

| Aluminium Alloy UNS A92024 Forged Caps | Aluminium Alloy UNS A92024 Forged Fasteners |

| Aluminium Alloy AISI 2024 Forged Billets | Aluminium Alloy AISI 2024 Forged Reducer |

| Aluminium Alloy UNS A92024 Forged Tee | Aluminium Alloy 2024 Forged Pipes |

| Aluminium Alloy 2024 Forged Tubes | Aluminium Alloy UNS A92024 Forged Circles |

| Aluminium Alloy 2024 Forged Square Bars | Aluminium Alloy 2024 Forged Valves |

| Aluminium Alloy AISI 2024 Forged Flat Bars | Aluminium Alloy UNS A92024 Forged Shafts |

| Aluminium Alloy 2024 Forged Rings | Aluminium Alloy 2024 Forged Discs |

| Aluminium Alloy AISI 2024 Forged Blocks | Aluminium Alloy UNS A92024 Forged Extrusions |

| Aluminium Alloy 2024 Forged Custom Shapes | Aluminium Alloy AISI 2024 Forged Machined Parts |

Popular Aerospace Aluminum Forgings from Haomei

Haomei Aluminum offers alloys including 2014, 2024, 2124, 2219, 2618, 2619, 3003, 5083, 6061, 7049, 7050, 7075, 7079, 7149, 7150, and 7175 tempers, available upon request, compliant with all AMS, ASTM, Boeing commercial, and Boeing military specifications.

| TYPE | SPECIFICATIONS |

| 2014 | AMS4133, 4134, 4314, AMS-A-22771 |

| 2024 | AMS-QQ-A-367 |

| 2219 | AMS4143, 4144, AMS-QQ-A-367, AMS-A-22771 |

| 2618 | AMS4132, AMS-QQ-A-367, AMS-A-22771 |

| 6061 | AMS4127, 4146, AMS-QQ-A-367, AMS-A-22771 |

| 7049 | AMS4111, AMS-QQ-A-367, AMS-A-22771 |

| 7050 | AMS4107, 4108, AMS-A-22771 |

| 7075 | AMS4126, 4131, 4141, 4147, AMS-QQ-A-367 |

| 7079 | AMS-QQ-A-367 |

| 7150 | AMS-A-22771 |

| 7175 | AMS4148, 4149, 4179, AMS-A-22771 |

2024 Aerospace Aluminum Forging FAQs

1. What is the operating temperature range for 2024 aluminum?

The operational upper-temperature range for 2024 aluminum alloy is not directly known, as it depends on the type of temper you are working with and the industrial applications.

2. Is 2024 aluminum good for welding?

No, 2024 aluminum can suffer from microcracking, leading to loss of structural integrity. As a result, it is not good for welding

3. How strong is 2024 aluminum?

2024 aluminum has a tensile strength of 290 – 450 MPa (42, 100 – 65, 300 psi).

4. What are the common trade names of 2024 aluminum?

Common trade names for aluminum 2024 include:

UNS A82024, UNS A82024, UNS A92024

Al2024-O, Al2024-T4, Al2024-T3

AA2024-T3,

Alclad 2024-T3, Alclad 2024-T4/T351, Alclad 2024-T851, and Alclad 2024-O

You may also be interested in the following

-

2024 T4 Aircraft Aluminum Sheet Plate for Fuselage Skins

The 2024-T4 aluminum alloy used for the fuselage skin features high strength, good formability, and excellent plate shape and surface quality.

-

7150 7055 2024 Aluminum for Aircraft Wing Panel

7150, 7055, 2024 have high strength, high toughness, corrosion resistance and other properties, suitable for manufacturing wing skin wall panels, wing ribs and webs and other structural parts.

-

7055 2024 Aluminum Plate for Aircraft Seats

7055 and 2024 aluminum alloy profiles are commonly used materials for manufacturing aircraft seats and are widely used due to their excellent performance.

-

2024 Aerospace Aluminum for Engine Cowl Skins

2024 high-strength aluminum is used for engine cowling skins because of its strength-to-weight ratio and high-temperature resistance, providing protection and optimal airflow.

-

2024 7075 Aerospace Aluminum for Door Components

2024 and 7075 high-strength aluminum alloys are used in aircraft door components to ensure durability, deformation resistance, and safety.

-

2024, 7075, and 7475 Aerospace Aluminum for Wing Skins

2024, 7075, and 7475 combinations exhibit excellent strength and fatigue resistance, making them suitable for wing skins to withstand deformation under stress.

-

2024 7075 Aerospace Aluminum for Fuselage Frames

2024, 7075, and 7475 aluminum alloys are essential materials in aerospace engineering, particularly for fuselage frames. Their unique properties enable engineers to select the most appropriate alloy based on specific requirements for strength, weight, corrosion resistance, and fatigue performance.

-

2024 7050 7075 Aerospace Aluminum for Horizontal Tail Fittings

Alloys 2024, 7050, and 7075 provide the necessary strength and stiffness for horizontal tail components of aircraft, ensuring reliable control surface performance.