2124 Aerospace Aluminum Sheet Plate

What is 2124 aluminum?

2124 aluminum is a high-strength alloy, belonging to the 2000 series (Al-Cu), known for its excellent strength-to-weight ratio and fatigue resistance. It is particularly suitable for aerospace and military applications, where the integrity of structures under stress is critical.

2124 aluminum alloy is a high-strength, heat-treatable alloy primarily used in aerospace applications. It is a higher-purity version of 2024 aluminum alloy, specifically developed for high-temperature environments.

After heat treatment, 2124 alloy exhibits high strength and hardness, making it suitable for manufacturing aircraft structures, spacecraft components, and other applications requiring high strength and low weight.

2124 aluminum alloy is typically supplied in the T851 temper, and 2124-T851 aluminum plate has significantly higher fracture toughness than 2024-T851, making it suitable for applications that require higher short transverse ductility, high strength, and excellent machinability. This alloy also has excellent exfoliation corrosion resistance, with fatigue performance similar to 2024-T851. It is widely used in high-performance structural components in the aerospace industry.

Characteristics of 2124 Aerospace Aluminum Plate

- High Strength: Compared to other aluminum alloys, 2124 offers excellent strength, making it suitable for structures that must withstand large loads. It maintains performance even at high temperatures (up to ~150°C).

- Corrosion Resistance: The corrosion resistance of 2124 aluminum is lower than that of the 6000/7000 series. While the corrosion resistance of aluminum-copper alloys is relatively poor, proper surface treatments can enhance its corrosion resistance. Coating or anodizing is often required.

- Fatigue Resistance: 2124 aluminum alloy is highly suitable for cyclic loading, which is critical in aerospace applications.

- Machinability: After appropriate heat treatment, 2124 aluminum offers good machinability and can undergo various machining processes.

- Heat Treatment: 2124 aluminum typically requires heat treatment to achieve optimal performance, with common processes including quenching and aging.

Specification of 2124 aerospace grade aluminum plate

| Temper | O, H112, T3, T4, T6, T351, T851, etc. |

| Thickness | 0.5mm-300mm |

| Width | 500-2650mm |

| Length | 500-12000mm |

| Standard | GB/T3880, GJB1541, GJB2662, ASTMB209, EN485, QQ-A-250/29, AMS 4101, etc. |

Popular 2124 Aluminum

| Product | Product Image | Description |

| Aluminum Sheet Plate 2124 T851 |

|

2124 T851 alloy plate is commonly used in the manufacture of aircraft structures, particularly in parts requiring high strength and excellent machinability. These applications include wing spars, fuselage frames, landing gear structures, and more, and it is widely used in aerospace applications where high-temperature and fatigue resistance are essential. |

| Aircraft Structures AA2124 T351 Aluminum Plate |

|

AA2124 alloy in the T351 temper has a high yield strength and good corrosion resistance, making it suitable for manufacturing structural components that need to withstand high pressure and stress. Compared to other common aluminum alloys, AA2124 T351 has better short transverse ductility, making it ideal for applications that require complex machining. |

Chemical composition of 2124 aerospace grade aluminium plate

| Element | Composition(%) |

| Si | 0.2 |

| Fe | 0.3 |

| Cu | 3.8-4.9 |

| Mn | 0.3-0.9 |

| Mg | 1.2-1.8 |

| Cr | 0.10 |

| Zn | 0.25 |

| Ti | 0.15 |

| Other | 0.2 |

| Al | Remainder |

Advantages of 2124 Aluminum

- High strength-to-weight ratio

- Good machinability

- Excellent corrosion resistance

Limitations of 2124 Aluminum

- Relatively high cost

- Difficult to machine, especially after heat treatment

2124 Aluminum Typical Mechanical Properties

| Thickness | Tensile Strength | Yield Strength | Elongation |

| In. | KSI | KSI | % |

| 1.001-2.00 | 66 | 57 | 5 |

| 5.001-6.00 | 63 | 54 | 4 |

2124 Aluminum Physical properties

| Coefficient of thermal expansion from 20 to 100°C | 22.9 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 23.8 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 24.7 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from -50 to 20°C | 21.1 K⁻¹10⁻⁶ |

| Density | 2.78 g/cm³ |

| Modulus of elasticity | 73 GPa |

| Shear modulus | 27 GPa |

| Specific heat | 882 J/(kg·K) |

| Thermal conductivity max. | 190 W/m*K |

| Thermal conductivity min. | 150 W/m*K |

Applications of 2124 Aircraft Aluminum Plate

Due to its high strength and resistance to stress corrosion cracking, 2124 aluminum is commonly used in aerospace structures, including aircraft wings, fuselage, and other critical components.

2124 aluminum plate is primarily used for aircraft structural components, wings, fuselage, and other load-bearing parts.

1. Aircraft Structural Components

2124 aluminum alloy is commonly used in the manufacturing of primary structural components for aircraft, such as frames, support beams, and other load-bearing structures. These parts need to withstand high loads and fatigue, making the strength and rigidity of 2124 aluminum alloy an ideal choice.

2. Wings

Wings are critical components of an aircraft, and 2124 aluminum alloy is often used in the primary load-bearing structures of wings, such as wing beams and ribs. Its high strength and fatigue resistance allow wings to effectively bear aerodynamic loads during flight.

3. Fuselage

In the design of aircraft fuselage, 2124 aluminum alloy is used to manufacture important load-bearing components, such as cross beams and longitudinal beams. These parts need to provide sufficient strength and stability to ensure the overall structural integrity of the aircraft.

4. Other Load-Bearing Components

In addition to wings and fuselage, 2124 aluminum alloy is also used in other load-bearing components, such as landing gear brackets, connectors, and other structural elements. These parts must withstand significant impacts and loads during flight and landing.

5. Military and Aerospace Applications

In military aviation and aerospace applications, 2124 aluminum alloy is widely used due to its excellent performance, particularly in components requiring high strength and low weight.

Haomei 2124 Aluminum Available Forms

2124 aluminum alloy is primarily available in plate form, suitable for applications requiring high strength and resistance to stress corrosion cracking.

| Product Form | Image | Description | Temper | Common Applications |

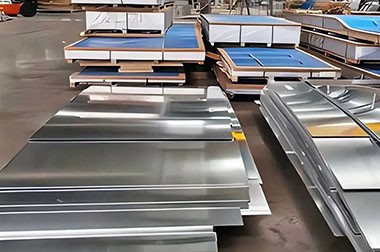

| 2124 Aluminum Plate |

|

2124 Aluminum Plate is the most widely available form, particularly in thicker sections, ranging from 0.25 inches (6.35 mm) to over 6 inches (152 mm), with standard widths up to 150 inches. | T851 (solution heat-treated, stress-relieved, aged) | Fuselage frames, wing skins, bulkheads, military armor components |

| 2124 Aluminum Sheet |

|

2124 Aluminum Sheet is a thinner alternative to plate, typically less than 0.25 inches (6.35 mm) thick, and is available in T3 or T851 temper. | T3 (solution heat-treated, cold-worked) or T851 | Aircraft skin panels, lightweight structural liners |

| 2124 Aluminum Bar and Rod |

|

2124 Aluminum Bar & Rod comes in solid forms, including round, rectangular, or hexagonal bars, with diameters ranging from 0.5 to 12 inches (12.7 to 305 mm), available in T851 or custom tempers. | T851 or custom tempers | Machined components, fasteners, high-stress fittings in aerospace and military applications |

| 2124 Aluminum Forgings |

|

2124 Aluminum Forgings are produced through closed-die or open-die forging processes, creating complex shapes and enhancing grain structure, ideal for high-load-bearing components. | T851 or other custom tempers | Landing gear components, engine mounts |

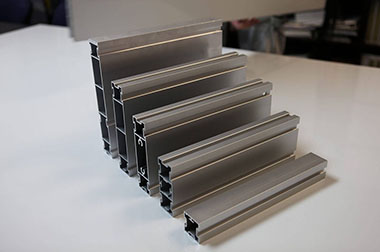

| 2124 Aluminum Extrusions |

|

2124 Aluminum Extrusions, though less common due to high strength and forming challenges, are available in shapes like channels, angles, or custom profiles, typically in T851 or T6 temper. | T851 or T6 | Specialized aerospace or defense applications requiring tailored profiles for structural components |

| 2124 Aluminum Custom Machined Parts |

|

2124 Aluminum Custom Machined Parts are supplied as near-net-shape parts, precisely machined to customer specifications with high tolerances, ideal for high-performance applications. | T851 or custom tempers | Critical aerospace and defense applications where precision and performance are crucial |

- Plate: AMS 4202, ASTM B209.

- Sheet/Bar: AMS 4035 or custom specifications.

- Certification: Mill Test Report (MTR) meeting chemical, mechanical, and non-destructive testing requirements.

- Surface Treatment: Mill finish, anodizing (e.g., Type II or Type III), or special coatings.

What is the difference between 2024 and 2124 aluminum?

2024 aluminum is commonly used in aircraft structural components, transport vehicles, and other applications requiring high strength.

2124 aluminum, with its superior high-temperature performance and corrosion resistance, is often used in high-performance components in the aerospace field, such as wing beams and fuselage structures.

Haomei Aluminum 2124 plate is available in the following sizes (all dimensions in inches)

Processing and Manufacturing

- Welding: Resistance welding is recommended; arc welding and gas welding are not recommended for 2124 alloy.

- Machinability: Suitable for conventional machining methods.

- Forming: 2124 can undergo limited cold working; severe cold working is not recommended.

Considerations

- Due to its uniform properties across the cross-section, it is very suitable for thicker sections.

- For applications requiring consistent strength in thicker plates, 2024 should be prioritized.

2124 aluminum plate is a cornerstone material for high-performance engineering, balancing strength, durability, and lightweight characteristics in demanding environments.

Why choose Haomei 2124 aerospace grade aluminum plate?

Haomei Aluminum offers a wide range of aluminum aircraft sheet and plate products to meet various aerospace application needs. Our products include a variety of standards such as AMS 4041, AMS 4037, AMS 4035, AMS 4049, AMS 4050, AMS 4048, AMS 4045, AMS 4044, AMS 4027, AMS 4026, AMS 4025, AMS 4347, and AMS 4202. In addition, we supply high-performance aluminum alloys such as 2219, 2124, 7175, 7475, 2024, 7075 T73, and 7075 T76 to meet the needs of customers in the aerospace and aviation industries.

| Grade | Temper | Surface | Specification |

| 2024 |

0, T3, T81, T351, T851 0, T3, T81, T351, T851 0, T3 |

BARE ALCLAD Clad 1 Side |

AMS-QQA250/4, AMS4035, AMS4037 AMS-QQA250/5, AMS4040, AMS4041, BMS7-305, AMS4036-AMS4077 |

| 2124 |

0, T3, T6, T351 T651 |

BARE ALCLAD |

AMS4029, AMS4028 AMS-QQA250/3 |

| 2219 |

0, T3, T81, T37 T87, T351, T851 |

BARE ALCLAD |

AMS-QQA250/30, AMS4031 AMS4095, AMS4096, AMS4094, DMS1719, BMS-7-110 |

| 2124 | T351, T851 | BARE | AMS-QQA250/29, GM2007, MMS-149, FMS-3002 |

| 6061 | 0, T6, T4, T651 | BARE | AMS-QQA250/11, AMS4025, AMS4026, AMS4027 |

| 6013 | T4 | BARE | AMS4347 |

| 7075 |

0, T6, T73, T76 T651, T7351 |

BARE ALCLAD |

AMS-QQA250/12, AMS-QQA250/24, AMS4044, AMS4045, AMS4078, AMS4315, MMS159 AMS-QQA250/13, AMS-QQA250/25, AMS4048, AMS4049, AMS4316, BMS7-302 |

| 7475 |

0, T6, T761, T7351 T7651 0, T61, T761 |

BARE BARE ALCLAD |

DMS2281, AMS4084, AMS4085, AMS4089, AMS4202F MS3004, CMS516-02 DMS2234, AMS4100, AMS4207 |

| 7050 | 0, T7451, T7651 | BARE | AMS4050, AMS4201, MMS1420, DMS2234, BMS7-323, CMS513-01/03 |

You may also be interested in the following

-

2124 2219 Aerospace Aluminum for Engine Support Structure

Alloys 2124 and 2219 are used in engine support structures due to their high strength and excellent fatigue resistance, providing durability under extreme conditions.