2219 Extruded Aluminum Profile for Aerospace

2219 aerospace aluminum profiles are a type of high-strength aluminum alloy primarily used in the aerospace field. Its main components include aluminum, copper, manganese, silicon, magnesium, and iron. The relatively high copper content gives it excellent strength and toughness.

Haomei Aluminum produces aerospace-grade aluminum extruded profiles according to specifications such as AMS 4153, ASTM-B221, UNS A92014, and QQ-A-200/2. 2219 Extruded Aluminum Profiles can be customized in size and specifications, with high quality and competitive prices.

Characteristics of 2219 Aerospace Aluminum Profiles

1. High Strength

2219 aluminum alloy is a high-strength aluminum alloy with superior tensile strength and yield strength, suitable for bearing heavy loads and high-stress aerospace applications.

2. Excellent Heat Resistance

The 2219 alloy maintains strength and stability at elevated temperatures, making it suitable for aerospace engines and other high-temperature environments.

3. Good Fatigue Performance

The 2219 aluminum alloy exhibits good fatigue strength under repeated loading conditions, extending the service life of aerospace components.

4. Moderate Corrosion Resistance

Although the corrosion resistance of 2219 is somewhat inferior to that of other aluminum alloys (such as 7075), it still possesses adequate corrosion resistance under specific conditions, making it suitable for use in certain harsh environments.

5. Weldability

The weldability of 2219 aluminum alloy is relatively good, especially when suitable welding techniques are used, ensuring the strength of the joints.

6. Good Machinability

The 2219 alloy can be processed through various methods such as extrusion, cold drawing, and milling, meeting the requirements for complex shapes and high precision.

7. Low Density

As an aluminum alloy, 2219 has a relatively low density, helping to reduce the weight of aircraft and improve fuel efficiency.

2219 Aluminum Extrusion Specifications

Currently offering to the following specifications:

AMS-4162, AMS-4163

ASTM-B221

Designer Specifications: BMS7-118, DMS-2077

Haomei Popular 2219 Aluminum Alloy Profiles

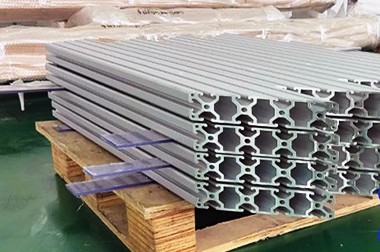

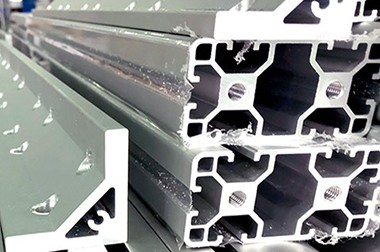

2219 Extruded Aluminum Profile

Characteristics

- Strong Formability: The 2219 aluminum alloy can be extruded into various shapes, such as round, square, rectangular, hexagonal, and custom profiles, accommodating different design needs.

- High Strength: 2219 aluminum alloy has high strength and heat resistance, making it suitable for structural components that bear significant loads.

- Good Weldability: Although the weldability of 2219 alloy is generally average, using appropriate welding methods (like TIG welding) can achieve strength and durability in aerospace applications.

- Corrosion Resistance: Compared to other aluminum alloys, 2219 has good corrosion resistance, making it suitable for use in harsh environments.

Aerospace Applications

- Aircraft Structural Components: 2219 extruded aluminum profiles are commonly used in the fuselage, wing beams, wing structures, and tail components of aircraft.

- Fuel Tanks and Storage Containers: Due to its high strength and corrosion resistance, it is suitable for manufacturing aerospace fuel tanks.

- Support Structures: Using 2219 profiles in aircraft support frames and other load-bearing structures enhances overall strength and safety.

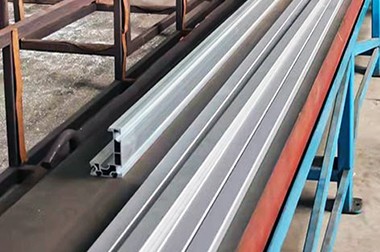

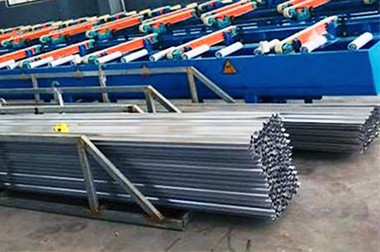

2219 Cold-Stretched Aluminum Profiles

Characteristics

- Precision Machining: The cold stretching process produces high-precision profiles with a smooth surface and stable dimensions.

- Increased Strength: During the cold stretching process, the grain structure of the aluminum alloy is optimized, enhancing its strength and hardness.

- Good Formability: The 2219 aluminum alloy can achieve complex cross-sectional shapes through cold stretching, suitable for various engineering design requirements.

- Lightweight: Compared to other materials, 2219 cold-stretched profiles maintain a lightweight, making them suitable for aerospace applications.

Aerospace Applications

- Slim Structural Components: Cold-stretched profiles are commonly used to manufacture slender parts of aircraft, such as control rods, connectors, and brackets.

- High-Strength Connectors: Due to their excellent strength and stability, they are suitable for high-load connection points both internally and externally in aircraft.

- Ducts and Pipelines: Used in aerospace systems for liquid and gas ducts, providing a lightweight and high-strength solution.

2219 aluminum profile chemical composition

| Chemical composition limits | |

| Weight% | Alloy 2219 |

| Si | ≤0.2 |

| Fe | ≤0.3 |

| Cu | 5.80-6.80 |

| Mn | 0.20-0.40 |

| Mg | ≤0.02 |

| Zn | ≤0.1 |

| Ti | 0.02-0.10 |

| V | 0.05-0.15 |

| Zn | 0.10-0.25 |

| Others | Each: 0.05 |

| Total: 0.15 | |

| Al | Bal |

Physical properties of AMS 2219 aerospace extruded aluminum profiles

| physical properties | AMS 2219 extruded aluminum profiles |

| density | 2.77 g/cm3 |

| melting point | 585-650°C |

| Thermal expansion coefficient | 23.8 µm/m°C |

| Thermal conductivity | 129 W/mK |

Mechanical properties of 2219 AMS 4163 2219-T3511 aerospace extruded aluminum profiles

| Mechanical behavior | AMS 4163 2219-T3511 Extruded Aluminum Profiles |

| 0.2% yield strength | 290 MPa |

| ultimate tensile strength | 470 MPa |

| elongation at break | 10% |

| hardness | 95 HRB |

Mechanical properties of 2219 AMS 4162 2219-T8511 aerospace extruded aluminum profiles

| Mechanical behavior | AMS 4162 2219-T8511 Extruded Aluminum Profiles |

| 0.2% yield strength | 290 MPa |

| ultimate tensile strength | 470 MPa |

| elongation at break | 10% |

| hardness | 95 HRB |

2000 Series Aluminum Alloy Profile

| Aluminum Alloy Products | Applications |

| 2014 Aluminum Alloy Extruded Profiles | 2014 aluminum alloy can be applied in situations requiring high strength, high hardness, and high temperature resistance. It can be used as aerospace materials, forgings, thick plates, extruded materials, wheels, structural components, spacecraft parts, first-stage fuel tanks of multistage rockets, truck frames, and suspension components. |

| 2219 Aluminum Alloy Extruded Profiles | 2219 aluminum alloy can be used for space shuttle oxidizer tanks, supersonic aircraft skins, and structural components. The operating temperature range for 2219 aluminum alloy is -270 to 300°C, featuring good weldability and high fracture toughness. In the T8 condition, this alloy exhibits good stress corrosion cracking resistance. |

| 2618 Aluminum Alloy Extruded Profiles | 2618 aluminum alloy can be used to manufacture forged parts and impact-forged components, as well as pistons and aircraft engine parts. |

| 2A50 Aluminum Alloy Extruded Profiles | 2A50 aluminum alloy is used to manufacture complex-shaped parts with high strength. |

| 2A70F Aluminum Alloy Extruded Profiles | 2A70F aluminum alloy is used to manufacture aircraft skins, aircraft engines, pistons, guide wheels, and discs. |

You may also be interested in the following

-

2124 2219 Aerospace Aluminum for Engine Support Structure

Alloys 2124 and 2219 are used in engine support structures due to their high strength and excellent fatigue resistance, providing durability under extreme conditions.