2219 Aerospace Aluminum Forgings

2219 aerospace aluminum forgings are a high-strength, high-temperature-resistant aluminum alloy widely used in the aerospace field.

2219 aluminum alloy is a high-strength alloy with good machinability and mechanical properties. It is useful in the temperature range of -452°F to 600°F, easy to weld, and exhibits good fracture toughness. In the T8 condition, it is resistant to stress corrosion cracking.

2219 aluminum is commonly used in various aerospace applications, such as high-temperature structural applications including space boosters and fuel tanks. The aerospace industry also benefits from the excellent corrosion resistance of 2219 aluminum forgings, which is crucial for the lifespan and reliability of aircraft components exposed to harsh environmental conditions.

2219 is a heat-treatable aluminum alloy that can be age-hardened and is typically used in high-temperature applications, particularly in aerospace. Heat treatment allows the alloy to achieve high strength but reduces ductility. Attractive characteristics include high resistance to stress corrosion and good fracture toughness.

Haomei Offers a Variety of Standard 2219 Aluminum Forgings

Grades

- AMS4143

- AMS4144

- AMSQQA367

- AMSA22771

Forms of 2219 Aerospace Grade Forgings

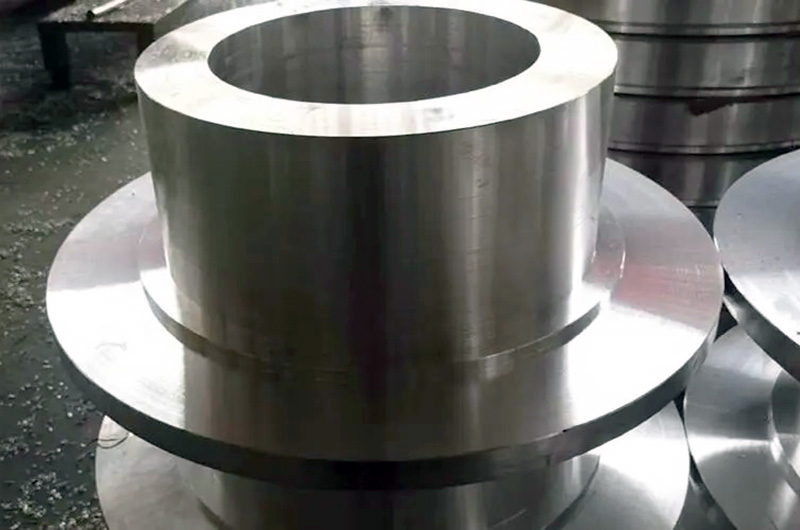

2219 Forgings

Available in various sizes and shapes to meet specific structural requirements, ensuring strength and precision.

2219 Bars

Standard and custom-sized bars are produced for use in manufacturing components and structural parts.

2219 Plates

Offered in different thicknesses, widely used for external structures and interior components of aircraft.

2219 Rings

Suitable for manufacturing bearings, gears, and other ring-shaped parts, ensuring high strength and durability.

2219 Complex Shape Forgings

Designed to meet specific design requirements, producing intricate geometries to optimize performance and reduce weight.

2219 Weldable Components

Forged parts that are suitable for welding, allowing for use in structural assemblies.

These forms ensure that 2219 aluminum alloy can deliver optimal performance across a variety of aerospace applications.

Properties of 2219 Aerospace Aluminum Forgings

- 1. High Strength: The 2219 alloy maintains good strength at high temperatures, allowing it to retain structural integrity under extreme conditions.

- 2. Corrosion Resistance: Compared to other aluminum alloys, 2219 has better corrosion resistance, making it suitable for aerospace environments.

- 3. Good Weldability: Although the weldability of 2219 alloy is not as high as that of some other aluminum alloys, good weld joints can still be achieved with proper treatment.

- 4. Fatigue Resistance: This alloy exhibits good fatigue performance under prolonged cyclic loads, making it suitable for components subjected to dynamic loads.

Advantages of 2219 Aerospace Aluminum Forgings

- 1. Lightweight: Compared to similar steel materials, aluminum forgings are lighter, helping to improve overall efficiency and reduce fuel consumption.

- 2. High Strength: Under the same conditions, the strength provided by 2219 is significantly higher than that of other commonly used aluminum alloys.

- 3. Durability: Excellent corrosion resistance and fatigue strength ensure stable performance over long-term use.

Chemical composition of 2219 aluminum forgings

| Element | AMS 4127 Requirements (wt. %) |

| Si | 0.4-0.8 |

| Fe | 0.7 max |

| Cu | 0.15 max |

| Mn | 0.15 max |

| Mg | 0.8-1.2 |

| Cr | 0.04 max |

| Zn | 0.25 max |

| Ti | 0.15 max |

| Al | balance |

| Other | 0.05 max |

Applications of 2219 Aerospace Aluminum Forgings

2219 aerospace aluminum forgings are widely used in the aerospace field due to their exceptional performance, ensuring the safe and efficient operation of aircraft and spacecraft under extreme conditions.

Aircraft Structural Components

High Strength-to-Weight Ratio: With its excellent strength and lightweight characteristics, 2219 aluminum alloy is an ideal material for aircraft structural frames. This alloy ensures that the aircraft maintains structural stability and safety under high loads while optimizing fuel efficiency.

Rockets and Spacecraft

High-Temperature and High-Stress Resistance: 2219 aluminum alloy exhibits outstanding high-temperature performance and stress resistance, making it suitable for manufacturing critical components of rocket engines, such as nozzles and combustion chambers. These components maintain structural integrity even in extreme environments, ensuring the successful launch and operation of spacecraft.

Fuel Tanks and Storage Tanks

Strength and Corrosion Resistance: Due to the good strength and corrosion resistance of 2219 alloy, it is often used to manufacture fuel tanks and storage tanks for aircraft. These containers effectively resist corrosion and other environmental influences during long-term storage and transportation of fuel, ensuring its safety and stability.

Popular Aerospace Aluminum Forgings from Haomei

Haomei Aluminum offers alloys including 2014, 2024, 2124, 2219, 2618, 2619, 3003, 5083, 6061, 7049, 7050, 7075, 7079, 7149, 7150, and 7175 tempers, available upon request, compliant with all AMS, ASTM, Boeing commercial, and Boeing military specifications.

| TYPE | SPECIFICATIONS |

| 2014 | AMS4133, 4134, 4314, AMS-A-22771 |

| 2024 | AMS-QQ-A-367 |

| 2219 | AMS4143, 4144, AMS-QQ-A-367, AMS-A-22771 |

| 2618 | AMS4132, AMS-QQ-A-367, AMS-A-22771 |

| 6061 | AMS4127, 4146, AMS-QQ-A-367, AMS-A-22771 |

| 7049 | AMS4111, AMS-QQ-A-367, AMS-A-22771 |

| 7050 | AMS4107, 4108, AMS-A-22771 |

| 7075 | AMS4126, 4131, 4141, 4147, AMS-QQ-A-367 |

| 7079 | AMS-QQ-A-367 |

| 7150 | AMS-A-22771 |

| 7175 | AMS4148, 4149, 4179, AMS-A-22771 |

You may also be interested in the following

-

2124 2219 Aerospace Aluminum for Engine Support Structure

Alloys 2124 and 2219 are used in engine support structures due to their high strength and excellent fatigue resistance, providing durability under extreme conditions.