6061 T6 T651 Aircraft Aluminum Plate Sheet

Is 6061 aluminum aircraft grade?

6061 aerospace aluminum plate is a commonly used aluminum alloy material, widely applied in aerospace, automotive, marine, construction, and machinery manufacturing.

What is 6061 aluminum plate?

6061 aluminum plate is a high-strength, good corrosion-resistant, and easy-to-machine aluminum alloy material. It has good heat treatment performance, can withstand significant stress, and exhibits good crack resistance. It is also easy to weld and process. However, the formability of 6061 aluminum plate is relatively poor. This material is commonly used in structural components that require high strength and corrosion resistance, such as frames, aerospace, ships, and automotive parts.

| Performance | Description |

| Welding | Excellent |

| Machining/Grinding | Good |

| Bending/Forming | Poor |

| Wear Resistance | Good |

| Corrosion Resistance | Good |

6061 aluminum alloy performs well in welding and machining, making it suitable for applications requiring high precision and strength. However, its bending and forming properties are relatively poor, so attention should be given to process design and treatment.

Features of 6061 Aircraft Aluminum

- High Strength: 6061 has high tensile and yield strength, suitable for bearing heavy loads.

- Good Corrosion Resistance: Performs excellently in various environments, especially resistant to seawater corrosion.

- Good Weldability: Can be welded using various methods (such as TIG and MIG) while maintaining material properties.

- Machinability: Easy to cut, shape, and process, making it suitable for manufacturing complex components.

Heat Treatment Conditions of 6061 Aircraft Aluminum Plate

- T6: Indicates that the material has undergone heat treatment (quenching and aging) to achieve maximum strength.

- T651: Indicates that stretching has been performed under T6 conditions to eliminate internal stress and improve material uniformity and stability.

Specification of 6061 Aircraft Aluminum Sheet

| Property | Details |

| Temper | O, T4, T6 |

| Specifications | 6061-T6, T651; ASTM B209; AMS-QQ-A-250/11 |

| Finish | Mill Finish, Not Polished, Smooth Surface |

| Available Sizes | 1' x 1', 1' x 2', 1' x 4', 2' x 2', 2' x 4', 4' x 4', 4' x 8', 4' x 10', 4' x 12', 5' x 12', or Custom Sizes and Shapes |

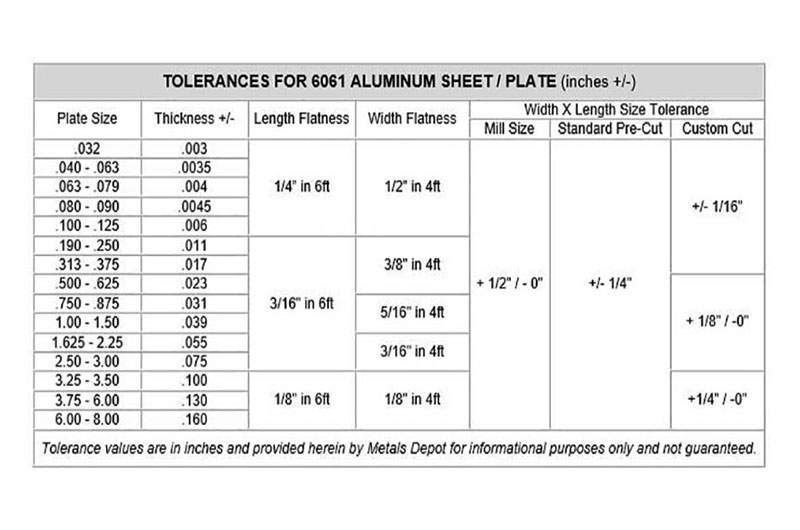

Tolerances for 6061 aluminum sheet/plate

6061 Aircraft Aluminum Chemical Composition

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Zr | Ti | Standard |

| 6061 | 0.40-0.8 | 0.7 | 0.15-0.40 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | - | GB/EN/AMS |

6061 Aircraft Aluminum Mechanical Properties

| Alloy | Temper |

Tensile strength(mm) RM(Mpa) |

Yield strength RP0.2(Mpa) |

Breaking elongation A50% |

Standard |

| 6061 | O | 130-145 | 65-75 | 25-35 | AMS-QQ-A25011 |

| T4 | 240-270 | 160-200 | 20-30 | AMS 4026 | |

| T6 | 320-360 | 260-290 | 15-25 | AMS 4027 |

Haomei Aluminum 6061 Aluminum Sheet Tempers

| Property | 6061-T4 Aluminum | 6061-T6 Aluminum | 6061-T651 Aluminum |

| Heat Treatment | Solution heat-treated and naturally aged | Aluminum 6061-T6 is artificially aged | Artificially aged and permanent set |

| Strength | Lower tensile and yield strength than T6 | Higher tensile and yield strength than T4 | Similar to T6, but with minimized internal stresses |

| Elongation | Higher elongation, increases formability | Lower elongation compared to T4 | Lower elongation compared to T4 |

| Cost | Less expensive than T6 | More expensive than T4 | Similar to T6, but additional processing costs |

| Formability | Better formability due to higher elongation | Lower formability than T4 | Similar to T6, but reduced internal stresses |

| Welding/Joining | Weldable | Weldable | Weldable |

| Anodizing | Can be anodized | Can be anodized | Can be anodized |

| Applications | Aircraft panels, automotive panels, trailer frames, packaging, etc. | Medical assemblies, heat sinks, hydraulic tubing, air coolers, aircraft fittings, electrical fittings | Aircraft and aerospace components, heavy-duty machinery, ramps, stairs, base plates, heavy structures |

Thickness options for Aluminum Sheet\Plate 6061-T6\T651

| Material | Temper | Shape | Thickness (t) |

| 0.02" 6061-T6 Aluminum Sheet | T6 | Sheet | 0.02" |

| 0.025" 6061-T6 Aluminum Sheet | T6 | Sheet | 0.025" |

| 0.125" 6061-T6 Aluminum Sheet | T6 | Sheet | 0.125" |

| 0.16" 6061-T6 Aluminum Sheet | T6 | Sheet | 0.16" |

| 0.19" 6061-T6 Aluminum Sheet | T6 | Sheet | 0.19" |

| 0.25" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 0.25" |

| 0.313" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 0.313" |

| 0.375" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 0.375" |

| 0.5" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 0.5" |

| 0.625" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 0.625" |

| 0.75" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 0.75" |

| 0.875" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 0.875" |

| 1" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 1" |

| 1.125" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 1.125" |

| 1.25" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 1.25" |

| 1.375" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 1.375" |

| 1.5" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 1.5" |

| 1.625" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 1.625" |

| 1.75" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 1.75" |

| 2" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 2" |

| 2.25" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 2.25" |

| 2.5" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 2.5" |

| 2.75" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 2.75" |

| 3" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 3" |

| 3.25" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 3.25" |

| 3.5" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 3.5" |

| 3.75" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 3.75" |

| 4" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 4" |

| 4.25" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 4.25" |

| 4.5" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 4.5" |

| 4.75" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 4.75" |

| 5" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 5" |

| 5.25" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 5.25" |

| 5.5" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 5.5" |

| 6" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 6" |

| 6.25" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 6.25" |

| 6.5" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 6.5" |

| 7" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 7" |

| 7.5" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 7.5" |

| 8" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 8" |

| 8.5" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 8.5" |

| 9" 6061-T6/T651 Aluminum Plate | T6/T651 | Plate | 9" |

Applications of 6061 Aerospace Aluminum

1. Aircraft Structural Components

Wing Frame

The wing is a crucial load-bearing structure of an aircraft. 6061 aluminum is used in the manufacturing of wing frames due to its excellent strength-to-weight ratio. The tensile and yield strength of 6061 aluminum alloy allow it to withstand various stresses and loads experienced during flight. Additionally, the good machinability of 6061 aluminum makes the manufacturing process of wing frames more efficient.

Fuselage and Tail

The fuselage is the main structure of the aircraft, and 6061 aluminum is used for the frame and outer shell of the fuselage, providing sufficient strength and rigidity. The tail, which is essential for the stability and control of the aircraft, typically also uses 6061 aluminum alloy to ensure flight safety and performance.

2. Internal Components

Seat Frames

Aircraft seats need to possess strength and lightweight characteristics. 6061 aluminum is widely used for seat frame manufacturing due to its good strength and low density. The corrosion resistance and wear resistance of 6061 aluminum alloy ensure the stability and safety of the seats during long-term use.

Baggage Compartment

The baggage compartment needs to withstand certain weights and impacts. The high strength and toughness of 6061 aluminum make it an ideal material. Its excellent corrosion resistance also ensures the long-term use of the baggage compartment in humid environments.

Other Internal Structures

Besides seat frames and baggage compartments, 6061 aluminum is also used in other internal structural components of the aircraft, such as aisle frames, partitions, and support structures. Its good weldability and machinability make the manufacturing and installation of these components more convenient.

How Strong is 6061 Aluminum Plate?

6061 aluminum plate is a common aluminum alloy that exhibits good strength and machinability. Its tensile strength typically ranges from 260 to 310 MPa (megapascals), while the yield strength is about 240 MPa. This makes 6061 aluminum plate suitable for various structural applications, including aerospace, automotive, and construction. The specific strength can also be affected by heat treatment and processing methods.

You may also be interested in the following

-

6061 Aircraft Aluminum for Seat Legs

The versatile 6061 aluminum alloy offers good mechanical properties, making it suitable for seat legs and providing strength and stability for aircraft seats.