6063 Aerospace Aluminum Profile Extrusions

What is 6063 Extruded Aluminum?

6063 extruded aluminum is an aluminum alloy that belongs to the aluminum-magnesium-silicon series and is primarily used for extrusion molding.

6063 alloy is one of the most popular alloys in the 6000 series, known for its excellent extrusion properties and high-quality surface finish.

6063 aluminum is an ideal choice for custom aluminum extrusion processes, offering good corrosion resistance, outstanding extrusion performance, and the ability to form into complex shapes.

6063 aluminum alloy extrusions, due to their machining properties, corrosion resistance, and surface treatment capabilities, are widely used for secondary structures and decorative components in the aerospace sector.

Advantages of 6063 Aluminum Extrusions

- 1. Excellent extrudability: 6063 aluminum alloy can be easily extruded into a variety of complex cross-sectional shapes, making it suitable for profiles used in structural and decorative applications.

- 2. Superior corrosion resistance: After anodizing, 6063 aluminum alloy exhibits enhanced corrosion resistance, making it ideal for environments requiring long-term exposure.

- 3. Balance of lightweight and strength: While 6063 aluminum alloy is not as strong as some high-strength aluminum alloys, its lightweight nature and sufficient strength make it ideal for secondary structures and non-load-bearing components.

- 4. Good surface treatment capability: 6063 aluminum alloy can undergo various surface treatments, including polishing and anodizing, making it suitable for interior and exterior decorative components in aircraft.

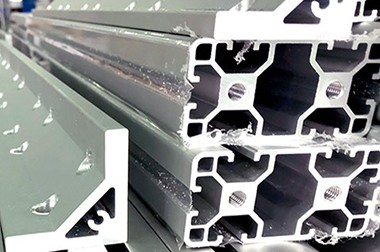

6063 Popular Extruded Profile Products

6063 aluminum alloy is widely used in secondary structures and decorative components in aerospace due to its excellent extrudability, good mechanical properties, and corrosion resistance. Below is a description of the characteristics of 6063 aluminum alloy in different extruded product forms:

6063 T5 Aluminum Profile

- Characteristics: The 6063 T5 profile is heat-treated, offering medium strength and good corrosion resistance. Its surface is smooth and easy to anodize.

- Applications: 6063 T5 aluminum profile is suitable for secondary frame structures, internal supports, and areas where lightweight and aesthetics are important in aerospace.

6063 Extruded Aluminum Angle

- Characteristics: 6063 angle profile has excellent extrudability and corrosion resistance, with precise angles, suitable for load-bearing components. It offers stable structure and ease of processing.

- Applications: 6063 extruded aluminum angles are commonly used in connecting components of internal and external structures in aircraft, such as cabin frames, brackets, or decorative elements.

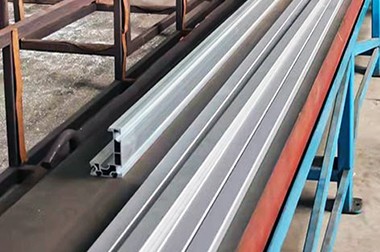

Aluminum T Slot 6063

- Characteristics: T-slot profiles feature precise slots and smooth surface treatment, providing convenience for fixing and assembly with moderate strength.

- Applications: Aluminum T Slot 6063 is used for assembling aerospace equipment, mounting platforms, or adjustable components inside the cabin.

Aluminum Extruded Channel 6063 T52

- Characteristics: The T52 condition provides good mechanical properties and corrosion resistance. The channel structure design helps support, guide, or protect cables and other components.

- Applications: Commonly used in aerospace structures as guide rails, supports, or frame components, Aluminum Extruded Channel 6063 T52 is often employed to support structures or protect electrical wiring inside aircraft cabins.

6063 Aluminum Extruded Flat Bar

- Characteristics: 6063 flat bar features a smooth surface and uniform thickness, with moderate strength and excellent machinability. It is easy to bend and weld.

- Applications: 6063 aluminum extruded flat bars are used to manufacture lightweight components in aerospace, such as interior fixing strips or lightweight frames.

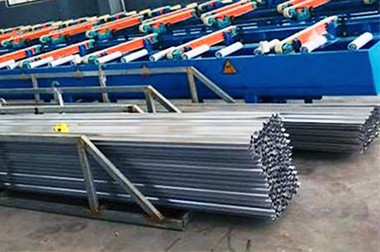

6063 Aluminum Extruded Round and Square Bars

- Characteristics: 6063 round and square bars offer good strength and rigidity, and are easy to machine, weld, and anodize, with excellent corrosion resistance.

- Applications: Used for manufacturing aerospace structural components such as support rods, shafts, frame parts, or for decorative and connecting purposes.

6063 Aluminum Extruded Round and Square Pipes

- Characteristics: 6063 aluminum pipes have moderate strength, lightweight, and good corrosion resistance, suitable for structural applications requiring lightweight and weather resistance.

- Applications: Commonly used in aerospace for hydraulic pipes, structural supports, internal and external frames, and cabin piping systems.

6063 Aluminum Extruded Round and Square Tubes

- Characteristics: 6063 tubes are lightweight, smooth-surfaced, with good corrosion resistance and moderate strength, suitable for demanding extrusion applications.

- Applications: Used in aerospace as frame support structures, ventilation ducts, external decorative components, or for light-load transmission parts.

6063 aluminum alloy comes in various product forms and is primarily used in aerospace for secondary structures and decorative components that require lightweight, corrosion resistance, and aesthetics.

Chemical composition of 6063 aerospace aluminum profiles

| Element | Composition % |

| Al | REM |

| Si | 0.2-0.6 |

| Fe | ≤0.35 |

| Cu | ≤0.1 |

| Mn | ≤0.10 |

| Mg | 0.45-0.90 |

| Cr | ≤0.10 |

| Ni | / |

| Zn | ≤0.10 |

| Ti | ≤0.10 |

| Note: EACH: ≤0.05; TOTAL: ≤0.15 | |

Mechanical properties of 6063 aluminum extrusion aerospace

| Temper | Dimensions /mm | Room temperature test result | |||

| Tension strength/MPa | Yield strength/MPa | Elongation/% | |||

| A50mm | A | ||||

| Not less than | |||||

| O/H111 | All | 120 | 65 | 18 | |

| T4 | All | 130 | 65 | 14 | |

| T5 | All | 175 | 130 | 8 | |

| T6 | All | 215 | 70 | 10 | |

| T66 | All | 245 | 200 | 10 | |

6063 Aluminum Extrusions in Aerospace Applications

1. Aircraft Cabin Frames and Brackets

6063 aluminum extrusions are commonly used for aircraft cabin frames and brackets. These components require a combination of lightweight and structural strength to ensure the stability and safety of the aircraft interior. 6063 aluminum alloy provides good rigidity, corrosion resistance, and can be extruded into complex geometries.

2. Window Frames and Porthole Decorative Borders

Due to its excellent surface treatment capability, 6063 aluminum alloy is widely used in the production of aircraft window frames and porthole decorative borders. These components usually require anodizing to increase corrosion resistance while maintaining a good appearance, and 6063 aluminum alloy easily meets these requirements.

3. Interior Support Components and Rails

The processing properties of 6063 aluminum extrusions make them suitable for manufacturing support components and rails in the aircraft cabin interior. These parts need to bear a certain load while ensuring aesthetic appeal and precise dimensional control. 6063 aluminum can be extruded and processed into various shapes, such as L-shaped, T-shaped, U-shaped, and Z-shaped profiles, to meet different structural requirements.

4. Overhead Luggage Compartment Rails and Mounting Brackets

The overhead luggage compartment rails and mounting brackets in the aircraft cabin are often made of 6063 aluminum alloy. Its extrusion properties allow the formation of complex profiles used to support and secure the luggage compartment while maintaining stability and lightweight in load-bearing conditions.

5. Cabin Floor Support Frames

6063 aluminum extrusions are also used in the support frames of aircraft cabin floors due to their good mechanical strength, fatigue resistance, and corrosion resistance, which meet the durability requirements of floor framing structures.

6. Cabin Decorative Strips and Edge Trims

Cabin edge trims, aisle dividers, and decorative borders around cabin doors are often made from 6063 aluminum alloy. Its excellent surface treatment capabilities allow it to provide visual appeal and long-lasting durability. Anodizing can further enhance its corrosion resistance.

What is the Difference Between 6061 and 6063 Extrusion?

The differences between 6061 and 6063 aluminum extrusions mainly lie in composition, mechanical properties, processing performance, and applications. 6061 focuses more on strength and durability, while 6063 emphasizes formability and appearance. The choice of alloy depends on the specific application requirements.

| Attributes | 6061 Aluminum Extrusion | 6063 Aluminum Extrusion |

| Main Alloy Components | Magnesium (0.8-1.2%), Silicon (0.4-0.8%), Copper, Chromium | Magnesium (0.45-0.9%), Silicon (0.2-0.6%) |

| Strength | Higher | Lower |

| Processing Performance | Good processing performance, but slightly inferior extrusion formability, suitable for complex structural processing | Excellent extrusion performance, easy to form complex cross-sections, and has good surface treatment effects |

| Corrosion Resistance | Good corrosion resistance, suitable for anodizing | Superior corrosion resistance, with a smooth and uniform surface after anodizing |

| Typical Applications | Mainly used for aerospace structural components, frames, spars, supports, engine parts, etc. | Mainly used for secondary structural components, decorative parts, door frames, window frames, and interior components in aerospace |

| Surface Finish | Moderate surface finish | Excellent surface finish, suitable for decorative products |

| Formability | Poor formability, difficult to process into complex or elongated profiles | Excellent formability, suitable for producing complex cross-sectional profiles and tubes |

| Application Fields | Aerospace, trucks, ships, industrial structures | Building window and door frames, radiators, decorative materials, secondary structural and decorative components in aerospace |