6082 T6 T651 Aerospace Grade Aluminum Sheet Plate

6082 aluminum alloy is primarily composed of aluminum, silicon, magnesium, and other elements, offering excellent mechanical properties and corrosion resistance. 6082 aerospace-grade aluminum plates are widely used in the aerospace industry and other high-performance sectors.

The 6082 alloy demonstrates good corrosion resistance in many environments, especially after anodizing, which can further enhance its corrosion resistance.

6082 aluminum alloy is a widely used alloy for structural and high-strength applications, belonging to the 6000 series. It combines good strength, corrosion resistance, and machinability. Due to its higher strength, 6082 has become a substitute for 6061 in certain high-stress applications.

The specifications for 6082 aerospace grade aluminum plate

| Alloy | 6082 |

| Temper | O, T4, T6, T651, T6511 etc. |

| Thickness | 0.5mm-300mm |

| Width | 500-2650mm |

| Length | 500-12000mm |

6082 Aerospace Aluminum Plate Characteristics

- High Strength: 6082 aluminum alloy has a higher strength, suitable for bearing large loads.

- Good Corrosion Resistance: This alloy exhibits excellent corrosion resistance in various environments.

- Excellent Machinability: 6082 aluminum alloy is easy to machine and weld, suitable for various manufacturing processes.

- Heat Treatment Strengthening: After heat treatment, the mechanical properties of 6082 aluminum alloy can be further enhanced.

The chemical composition of 6082 aviation aluminum sheet plate

| Element | Composition(%) |

| Si | 0.7-1.3 |

| Fe | 0.50 |

| Cu | 0.10 |

| Mn | 0.40-1.00 |

| Mg | 0.06-1.20 |

| Cr | 0.25 |

| Zn | 0.20 |

| Ti | 0.10 |

| Al | Remainder |

The typical mechanical performance of 6082 T6 aircraft aluminum sheet plate

| Material | Thickness (mm) | Tensile strength (N/mm2) min | Yield strength (N/mm2) min | Elongation on 50mm % (min) |

| Alloy 6082 T6 Sheet and Plate | 0.2-3.0 | 295 | 255 | 8 |

| Alloy 6082 T6 Sheet and Plate | 3.0-6.0 | 295 | 240 | 8 |

| Alloy 6082 T6 Sheet and Plate | 6.0-25.00 | 295 | 240 | 8 |

6082 T6 T651 aluminum plate physical properties

| Temper | T6 | T651 |

| Density | 2.70 g/cm³ | 2.68g/cm³ |

| Tensile Strength | 250-310MPa | >=295MPa |

| Elongation | 10% | 8% |

| Thermal Conductivity | 170 W/m-K | 220.0 W/m-K |

Haomei Aluminum supplies 6082 aluminum plates

Aluminium 6082 T6 plate

T6 refers to the heat treatment condition, which includes solution heat treatment followed by aging to improve strength.

Characteristics: It offers excellent strength, corrosion resistance, and good machinability. It is widely used in applications that require high strength and excellent fatigue resistance.

Applications: Commonly used in structural applications such as bridges, cranes, and other machinery, where strength and good surface finish are important. In the aerospace industry, 6082 T6 aluminum plates are often used for making fuselage structures, wing structures, propellers, etc.

Aluminium Alloy 6082 T4 Plate

T4 is a condition where the alloy undergoes solution heat treatment followed by natural aging to achieve a stable state. It has good strength but is lower than T6.

Characteristics: It offers good machinability and excellent weldability. It also provides a balance of strength and flexibility, but with lower strength than T6.

Applications: Typically used in applications requiring formability and moderate strength, such as vehicle frames and other lightweight structures in the transportation industry. In the aerospace field, 6082 T4 aluminum plates are often used for making structural parts with lower strength requirements, such as cabin interiors and seat structures.

6082-T651 Aluminum Plate

T651 is similar to T6, but it includes a stress-relieving process that reduces residual stress caused by machining. This gives the plate better dimensional stability and excellent surface finish.

Characteristics: It has the same high strength and corrosion resistance as T6 but offers better machinability and lower internal stress.

Applications: Used in aerospace, marine, and automotive industries for structural parts requiring high strength, precision, and dimensional accuracy.

In general, 6082 aluminum is a versatile alloy suitable for applications requiring good strength, durability, and corrosion resistance. Different conditions (T4, T6, T651) offer varying balances of strength, formability, and stability.

Applications of 6082 Aerospace Aluminum Plate

Aerospace

Used for manufacturing aircraft structural components and other aerospace parts.

Airframe Frames and Ribs

Used for the internal framework and ribs of the fuselage, providing necessary strength and rigidity to ensure structural stability.

Fuselage Skin Material

Used for the external skin of the aircraft, the strength and lightweight properties of 6082 help improve flight efficiency and reduce fuel consumption.

Wing Structure

Used for wing beams, ribs, and other components to enhance flight stability and load-bearing capacity.

Landing Gear

Used for landing gear components, which require high strength and corrosion resistance to withstand impact during landing and environmental effects.

Fuel Tanks

Due to its superior sealing properties, 6082 aluminum alloy is also used in the structure of fuel tanks to ensure safe and effective fuel storage.

Processing Methods for 6082 Aerospace Aluminum

6082 aluminum plates can be processed in various ways, including:

- Cutting: Precision cutting can be performed using laser cutting, waterjet cutting, and other methods.

- Bending: Forming can be done using a bending machine.

- Welding: Connections can be made using TIG welding, MIG welding, and other methods.

- Surface Treatment: Surface treatments such as anodizing and coating can be applied to enhance corrosion resistance and aesthetics.

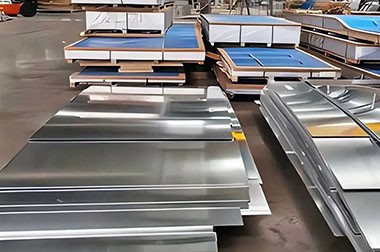

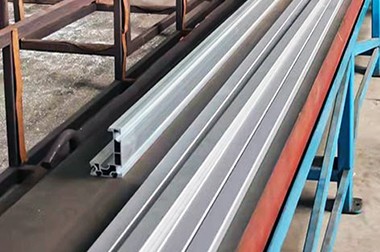

Haomei 6082 T6 T651 aluminum plate in stock

What is the difference between 6061 and 6082 aluminum?

6082 aluminum alloy is commonly used for manufacturing structural components, bridges, building frames, etc., especially in applications requiring high strength.

6061 aluminum alloy is widely used in construction materials, automotive parts, aerospace, and mechanical engineering.

What is the difference between Al 7075 and Al 6082?

In aerospace applications, 7075 aluminum alloy is often used for aircraft frames, wings, and other critical structural components due to its high strength and low weight. In contrast, 6082, with lower strength than 7075, is more commonly used for non-critical structures.