6082 Aluminum Round Bar

6082 aluminum round bar is an aluminum alloy material mainly composed of magnesium (Mg) and silicon (Si), featuring high strength, corrosion resistance, and ease of machining, and is widely used in industrial fields.

6082 aluminum round bar is a high-strength, heat-treatable alloy in the 6000 series, primarily consisting of aluminum, magnesium, and silicon. It is renowned for its excellent machinability, weldability, and corrosion resistance, making it suitable for various structural and engineering applications.

As a professional aluminum alloy material manufacturer, Haomei Aluminum offers 6082 aluminum alloy round bars that comply with the GB/T 3191-2019 standard, adopting a high-quality Al-Mg-Si alloy formula and strict heat treatment process (T6 condition) to ensure products with medium strength, excellent corrosion resistance, and good weldability.

6082 Aluminum Round Bar Available Shapes and Sizes

- Round bar: Diameter 5-200 mm; Length 3 meters/6 meters (standard).

- Surface treatment: Mill finish, anodizing, powder coating.

- Temper: T4 (solution heat treated), T6 (peak strength), T651 (stress relieved).

Compliance Standards

- EN 573-3 (Chemical Composition).

- EN 755-2 (Mechanical Properties of Rods).

- ASTM B211 (Equivalent American Standard).

6082 Aluminum Round Bar Heat Treatment

T6 process: Solution treatment temperature is about 530°C, followed by water quenching, and then artificial aging at about 160-180°C.

Enhances strength and hardness while maintaining ductility.

6082 Aluminum Round Bar Advantages

- Strength: Superior to 6061, with comparable weldability.

- Corrosion Resistance: Excellent, especially suitable for marine environments; anodizing further enhances corrosion resistance.

- Machinability: Good (machinability improved by 70% compared to free-cutting brass).

- Sustainability: Fully recyclable.

6082 Aluminum Round Bar Chemical Composition

The typical chemical composition of 6082 aluminum alloy is as follows:

- Aluminum (Al): 95.2–98.3%

- Silicon (Si): 0.7–1.3%

- Iron (Fe): ≤0.5%

- Copper (Cu): ≤0.1%

- Manganese (Mn): 0.4–1.0%

- Magnesium (Mg): 0.6–1.2%

- Chromium (Cr): ≤0.25%

- Zinc (Zn): ≤0.2%

- Titanium (Ti): ≤0.1%

- Other elements: ≤0.15%

6082 Aluminum Round Bar Mechanical Properties

The mechanical properties of 6082 aluminum round bar vary with temper:

Tensile Strength:

T4: 120–230 MPa

T6: 270–330 MPa

T651: 270–320 MPa

T6511: 320–340 MPa

Yield Strength: approximately 200 MPa

Brinell Hardness: range: 40 to 95, depending on temper

Elongation at Break: range: 6% to 16%, depending on temper

Modulus of Elasticity: approximately 69 GPa

Density: 2.70 g/cm³

Melting Point: approximately 555°C

These properties make it suitable for applications requiring high strength and durability.

6082 Aluminum Round Bar Physical Properties

- Density: 2.7 g/cm³

- Melting Point: ~555°C

- Thermal Conductivity: ~170 W/m·K

- Electrical Conductivity: ~50% IACS

6082 Aluminum Round Bar Manufacturing and Processing

There are various production methods for 6082 aluminum round bars:

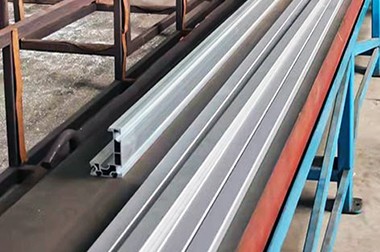

- Extrusion: commonly used to produce bars with uniform cross-sectional shapes.

- Cold Working: enhances surface finish and dimensional accuracy.

- Forging: used for manufacturing high-strength components.

The diameter of these bars ranges from 5 mm to 350 mm, with lengths up to 6 meters, and can also be customized according to requirements.

6082 Aluminum Round Bar Applications

Applications of 6082 Aluminum Round Bar in the Aerospace Field

Aerospace: aircraft wings, fuselage structures, and aerospace components.

In which other fields is 6082 Aluminum Round Bar used?

- Marine: hulls and superstructures of ships.

- Automotive: chassis components and suspension systems.

- Construction: structural components such as beams and columns.

- General Engineering: mechanical components and other structural parts.

- Structural Components (bridges, frames).

- Bicycle frames, CNC machined parts, and welded assemblies.

6082 Aluminum Round Bar Advantages

- High Strength: suitable for demanding structural applications.

- Excellent Machinability: easy to cut, drill, and machine.

- Weldability: compatible with various welding methods, including TIG and MIG.

- Corrosion Resistance: performs excellently in marine and industrial environments.

- Formability: can be easily shaped into different forms for specific applications.

6082 Aluminum Round Bar Limitations

- Lower Ductility: heat treatment reduces ductility, making it less suitable for applications requiring significant deformation.

- Non-Work Hardenable: strength cannot be increased through work hardening; it relies on heat treatment instead.

Comparison with 6061

- Higher silicon content improves extrusion performance and strength.

- More popular in Europe, whereas 6061 is more common in the United States.

6082 Aluminum Round Bar Production Process

Melting

Temperature is controlled between 740–760°C to ensure uniform distribution of refractory elements such as magnesium and manganese.

Purification and Casting

Nitrogen gas and refining agents are used for degassing and slag removal. Double filtration (foam ceramic + fiberglass) is employed during casting to reduce oxide inclusions.

Heat Treatment

T6 temper requires solution treatment followed by artificial aging to significantly enhance mechanical properties.

6082 aluminum round bar combines strength, machinability, and corrosion resistance, making it the preferred choice for a variety of structural and engineering applications.