7014 Aerospace Aluminum Profile Extrusion

7014 aluminum alloy is a high-strength aluminum alloy primarily used in the aerospace industry, especially in structural components and high-load parts. Its extruded profiles exhibit excellent mechanical properties and good machinability, making them suitable for critical structural components of aircraft.

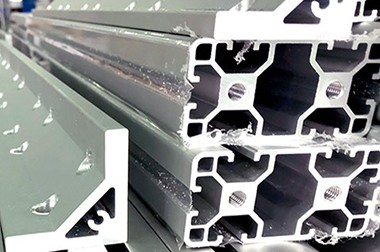

Characteristics of 7014 Aerospace Aluminum Profile Extrusion

- 1. High Strength: 7014 aluminum alloy has high tensile and yield strength, suitable for bearing large loads. This makes it ideal for key structures in the aerospace field, such as wings, fuselage frames, and landing gear.

- 2. Good Weldability: 7014 alloy performs well during welding, enabling reliable connections, which is suitable for the assembly of complex structures.

- 3. Corrosion Resistance: Although not as good as some other aluminum alloys, 7014 alloy has a certain level of corrosion resistance, making it suitable for use in aerospace environments.

- 4. Good Extrudability: 7014 aluminum alloy has excellent extrusion performance, allowing for the production of complex profiles.

- 5. Heat Treatment States: Common heat treatment states include T6 (solution heat-treated and artificially aged), under which its mechanical properties are optimized.

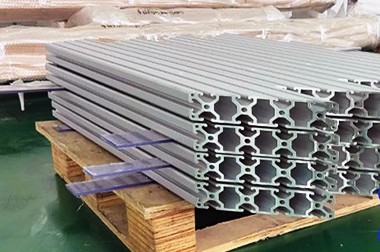

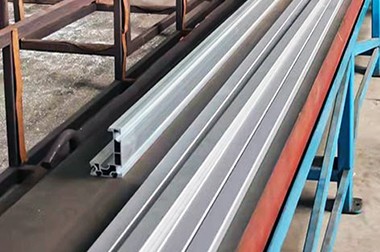

Popular 7014 Aluminum Profile Extrusions by Haomei

7014 T4 Aluminum Profile

The T4 temper of 7014 aluminum is achieved through solution heat treatment followed by natural aging. This results in a relatively high strength level while maintaining good workability and ductility.

7014 T4 Aluminum Profile Applications in Aviation

The T4 profile is often used in structural components of aircraft that require a balance of strength and formability, such as support beams and aircraft frames.

7014 T6 Aluminum Profile

The T6 temper is achieved through solution heat treatment and artificial aging, providing enhanced strength and hardness compared to the T4 temper. It exhibits excellent mechanical properties.

7014 T6 Aluminum Profile Applications in Aviation

T6 profiles are commonly utilized in high-stress applications like aircraft fuselage components, wing structures, and landing gear components where strength is critical.

7014 T6511 Aluminum Profile

The T6511 temper involves solution heat treatment, stress relieving, and aging, offering improved dimensional stability and toughness. This temper is ideal for applications that require enhanced stress resistance.

7014 T6511 Aluminum Profile Applications in Aviation

This profile is ideal for components that undergo cyclic loading, such as aircraft frames and heavy-duty supports, where the combination of strength and resistance to deformation is essential.

7014 L-Shaped Aluminum Extrusion

L-shaped extrusions have a right-angle cross-section, providing structural integrity and versatility. They are available in various thicknesses and dimensions.

7014 L-Shaped Aluminum Extrusion Applications in Aviation

L-shaped profiles are frequently used in aircraft floor beams, wing spars, and brackets, providing support and structural reinforcement in various assemblies.

7014 I-Shaped Aluminum Profile

I-shaped profiles are characterized by their vertical and horizontal flanges, offering high resistance to bending and shear forces.

7014 I-Shaped Aluminum Profile Applications in Aviation

These profiles are often used in the design of fuselage frames, wing structures, and other critical load-bearing components, providing optimal weight-to-strength ratios.

7014 U-Shaped Aluminum Profile

U-shaped profiles have a trough-like design, providing high rigidity and strength. They are available in varying depths and widths.

7014 U-Shaped Aluminum Profile Applications in Aviation

U-shaped extrusions are typically used in structural components such as skin stringers and reinforcement in aircraft assemblies, where they provide effective load distribution.

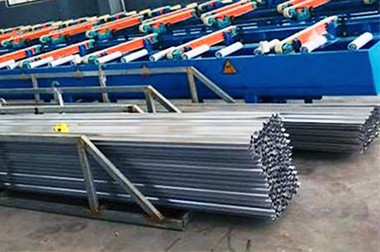

7014 Aluminum Round Bar

Round bars made from 7014 aluminum alloy are characterized by their circular cross-section, offering excellent strength and machinability.

7014 Aluminum Round Bar Applications in Aviation

These bars are used for manufacturing components like fittings, shafts, and fasteners, where high strength and lightweight characteristics are essential.

7014 Aluminum Pipe

7014 aluminum pipes are hollow tubes that can be produced in various diameters and wall thicknesses, providing a lightweight solution with good mechanical properties.

7014 Aluminum Pipe Applications in Aviation

Aluminum pipes are often employed in aircraft hydraulic systems and fuel lines, where their strength and corrosion resistance are vital for performance and safety.

Chemical composition of 7014 aluminum alloy

| 7014 Alloy % | |

| Si | 0.50 |

| Fe | 0.50 |

| Cu | 0.30-0.70 |

| Mn | 0.30-0.70 |

| Mg | 2.20-3.20 |

| Cr | - |

| Ni | 0.10 |

| Zn | 5.20-6.20 |

| Ti+Zr | 0.20 |

| Al | Remainder |

Mechanical property of 7014 T4/T6 aluminum profile extrusion

| Alloy Temper | Tension strength | Yield strength | Elongation | Hardness |

| T4 | 480 MPa | 360 MPa | 11% | 130 HV |

| T6 | 510 MPa | 470 MPa | 10% | 145 HV |

| T6511 | 510 MPa | 470 MPa | 10% | 145 HV |

Specific Applications of 7014 Aluminum Profiles in the Aerospace Field

1. Aircraft Structural Components

7014 aluminum profiles can be used to manufacture the frames and support structures of aircraft. These structural components require high strength to withstand various loads encountered during flight. The high strength and good fatigue resistance of 7014 aluminum alloy make it an ideal choice for such applications.

2. Wings and Fuselage

In some light aircraft, 7014 aluminum profiles are used in the manufacturing of wings and fuselage. These components need to have a good strength-to-weight ratio; 7014 aluminum alloy can provide sufficient strength while maintaining a relatively low weight, thus enhancing the aircraft's performance and efficiency.

3. Landing Gear Components

Due to its high strength and wear resistance, 7014 aluminum alloy is often used in landing gear components. These parts must endure high impacts and repeated loads, so using 7014 aluminum alloy can improve the overall performance and reliability of the landing gear.

4. Attachments and Connectors

7014 aluminum profiles are also widely used in various attachments and connectors on aircraft. These connectors require high strength and corrosion resistance, and the properties of 7014 aluminum alloy can meet these demands.