7014 T651 T7451 T79 Aerospace Aluminum Sheet Plate

7014 aluminum alloy is a commonly used material in aerospace and military fields, belonging to the aluminum-zinc-magnesium alloy series.

7014 aluminum alloy is a high-strength alloy, part of the 7xxx series (Al-Zn-Mg-Cu), renowned for its excellent strength-to-weight ratio. Although it is not as common as 7075 or 7050, it is recognized in specific standards.

7014 aluminum plate is a high-performance aerospace-grade material, specifically designed for applications where lightweight, high strength, and reliable performance under cyclic loads are critical, such as aircraft fuselage, wing beams, and other structural components.

7014 Aircraft Aluminum Processing Characteristics

7014 aluminum alloy can be formed through various processing methods, including:

- Heat Treatment: Strength can be enhanced through processes like T6.

- Cold Working: Suitable for extrusion, rolling, and other processes.

7014 aircraft aluminum alloy product specification

| specification | |

| Alloy | 7014 |

| Temper | O, T6, T651, T7451, T79 |

| Thickness | DTD 5110, AMS-QQ-A-250/13, ASTM B209-14, EN 485-2 |

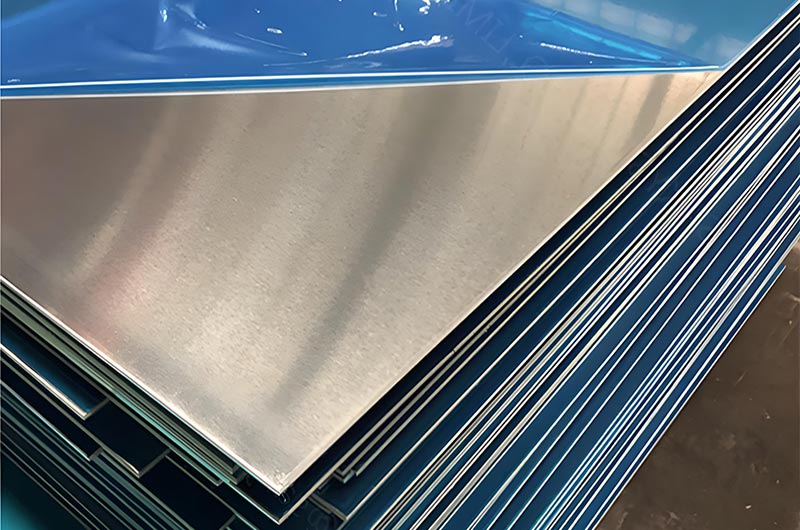

7014 aluminum plate is typically manufactured as a composite plate (bonding a thin layer of pure aluminum to the core alloy) to enhance corrosion resistance and surface quality without affecting strength.

7014 Aluminum Plate Temper

7014 comes in a variety of heat-treated conditions, including O (annealed), T6 (solution heat-treated and artificially aged), T651 (T6 with stretching treatment for improved dimensional stability), T7451 (optimized for high strength and crack resistance), and T79 (designed for high-temperature service).

The mechanical properties and applicability of 7014 aluminum alloy vary in different heat treatment states. T651 is suitable for general aerospace structures, T7451 is used for parts with higher strength requirements, while T79 offers superior overall performance under specific conditions.

7014 T651 Aerospace Aluminum Plate

T651: This heat treatment state indicates that the aluminum alloy has undergone heat treatment and natural aging, resulting in higher strength and good stability. It is suitable for applications that require high strength and good workability.

7014 T651 exhibits good ductility and machinability.

7014 T651 aerospace aluminum is suitable for aerospace structural components, frames, and load-bearing parts.

7014 T7451 Aerospace Aluminum Plate

T7451: This state indicates that the aluminum alloy has undergone special treatment, providing excellent strength and good corrosion resistance. It is commonly used for aerospace structural components and other high-demand applications.

7014 T7451 has good fatigue strength and crack resistance.

7014 T7451 aerospace aluminum is suitable for aerospace components that require extremely high strength and durability, such as wings and fuselage structures.

7014 T79 Aerospace Aluminum Plate

T79: This state is achieved through special heat treatment, mainly used to meet specific performance requirements. T79 aluminum alloys are typically used in aerospace due to their ability to maintain good strength and toughness at high temperatures.

7014 T79 has good corrosion resistance and fatigue performance.

7014 T79 aerospace aluminum can be used in structural components of high-performance aircraft, especially when operating under high stress and extreme environments.

Advantages of 7014 Aircraft Aluminum Alloy

- 1. High Strength: 7014 aluminum alloy has excellent tensile and yield strength, meeting the stringent performance requirements of the aerospace industry.

- 2. Lightweight: Compared to other metal materials, the lightweight properties of aluminum alloys help reduce aircraft weight, thus improving fuel efficiency and payload capacity.

- 3. Corrosion Resistance: Surface treatments of 7014 aluminum alloy enhance its corrosion resistance, extending the lifespan of components, especially in harsh environmental conditions.

- 4. Good Machinability: 7014 aluminum plates are easy to process and form, suitable for large-scale production and the manufacture of complex structures.

Applications of 7014 Aerospace Aluminum Plate

1. Aircraft Structural Components

7014 aluminum plates are often used to manufacture key structural components of aircraft, such as fuselage frames, wing supports, and tail surfaces, due to their high strength and good corrosion resistance. These components need to withstand complex loads and stresses, and the strength characteristics of 7014 aluminum plates meet these requirements.

2. Fuselage

In the manufacture of aircraft fuselages, 7014 aluminum plates are used for both load-bearing and non-load-bearing structures. Due to their excellent formability and weldability, 7014 aluminum plates can be processed into various shapes to meet different design requirements. Additionally, their lightweight properties help improve the aircraft's fuel efficiency.

3. Wings

7014 aluminum plates play a crucial role in wing manufacturing, particularly in the skeleton and shell sections of the wing. The high-strength aluminum alloy ensures that the wing can withstand aerodynamic drag and wind pressure during flight, providing adequate strength and stability.

4. Other Components

In addition to the major components mentioned above, 7014 aluminum plates can also be used to manufacture various other parts of the aircraft, such as landing gear, control surfaces, and bulkheads. These components also require high strength, corrosion resistance, and good machinability.

7014 aluminum alloy chemical composition

| Chemical composition | |||||||||

| chemical composition | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

| maximum value | 0.4 | 0.5 | 0.1 | 0.3 | 1.2 | 0.25 | 0.25 | 0.15 | margin |

7014 aluminum plate sheet physical properties

| Standard | Density | Expansion Thermal | Conductivity | Conductivity |

| DTD 5110 7014Clad aluminium Plate | 2.78 g/cm³ | 23.8 μm/m·°C | 124 W/(m·K) | 32.7 MS/m |

| AMS-QQ-A-250/13 7014 aluminium plate | 2.78 g/cm³ | 23.1 x 10^-6/℃ | 121 W/m-K | 0.035 μΩ-m |

7014 clad aluminium plate physical properties

| Tensile strength | Yield strength | Elongation | Hardness |

| 470-510 MPa | ≥345 MPa | ≥6% | 135-150 HV |

7014 Aluminum Alloy Compared to Other Alloys

- Compared to 7075: Similar strength; 7014/7A14 in T73 may offer better stress corrosion resistance.

- Compared to 6061: Higher strength, but lower corrosion resistance, and more difficult to weld.

| Comparison | 7014 Aluminum Alloy vs. 7075 Aluminum Alloy | 7014 Aluminum Alloy vs. 6061 Aluminum Alloy |

| Tensile Strength | 7014 has similar tensile strength to 7075, and it provides the same strength requirements in many structural components. | 7014 has significantly higher tensile strength than 6061, performing better under extreme load conditions. |

| Stress Corrosion Resistance | 7014 in the T73 heat treatment state exhibits superior stress corrosion resistance, especially in harsh environments, making it more reliable than 7075. | 7014 has poorer corrosion resistance and is less suitable for environments requiring high corrosion resistance, such as marine environments. |

| Application Areas | 7014 is more reliable than 7075 in fields such as aircraft exteriors, ship structures, and other areas requiring corrosion prevention. | 7014 is suitable for parts subjected to large operational loads, but less suitable in corrosive environments than 6061. |

| Machinability | Machinability is similar to 7075, but welding connections in some high-demand applications may be more complex. | 6061 offers better machinability and weldability than 7014, which requires more control and special techniques when welding. |

| Weldability | Welding 7014 is challenging, especially for high-quality welding. | 6061 has excellent weldability, suitable for various welding applications. |

7014 Aluminum Alloy Manufacturing and Processing

- Heat Treatment: Solution heat treatment (T6 temper) achieves peak strength; T73 temper enhances stress corrosion resistance.

- Workability: Medium; due to its high strength, hard alloy tools are required.

- Weldability: Challenging; TIG/MIG methods can be used, but post-weld aging may be required.

- Formability: Limited in the aged state; best formability in the annealed state.

7014 Aluminum Alloy Limitations

- Susceptible to stress corrosion cracking (T73 temper can alleviate this).

- Lower corrosion resistance compared to 5xxx/6xxx alloys.

- 7014 aluminum alloy is more expensive and has higher processing complexity.

7014 aluminum plate is a versatile, high-strength material that combines excellent physical and mechanical properties. Its customized heat treatment and precise chemical composition ensure it meets the demanding requirements of aerospace and military industries, where safety, performance, and weight reduction are crucial.