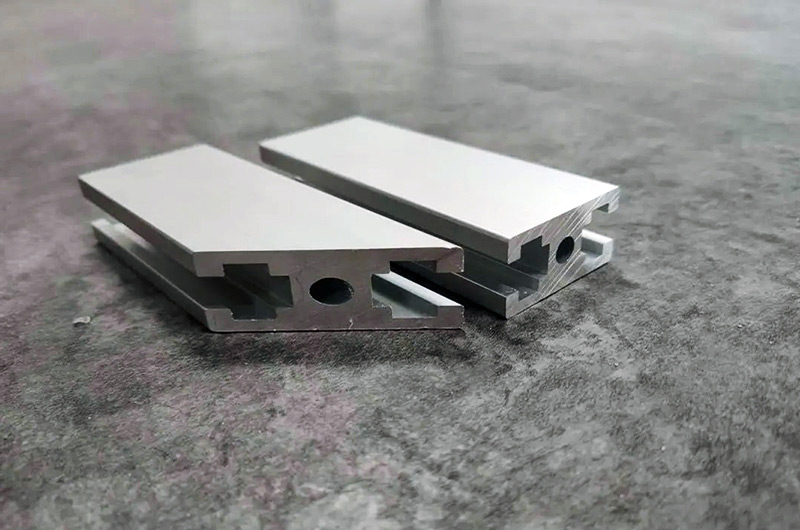

7049 Aircraft Aluminum Profiles

7049 aerospace aluminum alloy is a high-strength aluminum alloy, primarily composed of aluminum, zinc, magnesium, copper, and small amounts of other elements.

The 7049 aluminum alloy not only enhances the strength and safety of structures in the aerospace field but also effectively reduces the overall weight of aircraft, improving fuel efficiency and range performance.

Due to its high strength, high hardness, good machinability, and corrosion resistance, 7049 aluminum alloy is widely used in aerospace, military, and high-performance industrial applications.

Advantages of 7049 Aerospace Aluminum Alloy

1. High Strength and Low Weight

Strength-to-weight ratio: The 7049 aluminum alloy has exceptionally high tensile strength while maintaining a low density (approximately 2.8 g/cm³), making it outstanding in terms of strength-to-weight ratio. This characteristic is crucial in aircraft design, as reducing weight while ensuring structural safety and performance can significantly enhance fuel efficiency and load capacity.

Design flexibility: Due to the high-strength characteristics of 7049 aluminum alloy, designers can use thinner materials in aircraft structure design, which helps to reduce the overall weight without compromising strength and safety. This lightweight design not only improves aircraft performance but also extends its lifespan.

2. Excellent Machinability

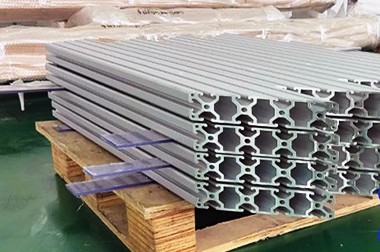

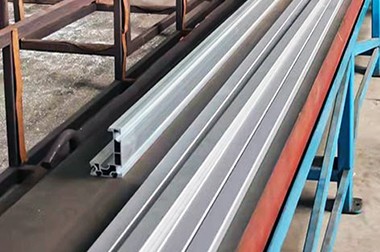

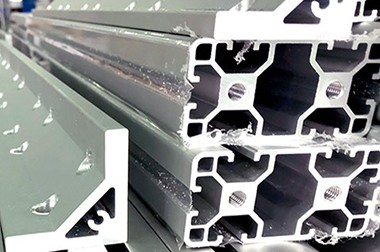

Various machining methods: The good machinability of 7049 aluminum alloy allows for the production of various complex shapes and sizes of aluminum profiles.

Heat treatment performance: Through appropriate heat treatment (such as T6 or T651), the strength and hardness of 7049 aluminum alloy can be further enhanced. This heat treatment capability enables aluminum profiles to meet the stringent performance requirements during the machining process, suitable for the aerospace field's high standards for material strength and reliability.

Surface treatment: The 7049 aluminum alloy is also easy to undergo surface treatments, such as anodizing or coating, to enhance its corrosion resistance and wear resistance. This treatment not only improves the durability of the material but also enhances its appearance, meeting the dual demands of aesthetics and durability in aircraft.

3. Good Fatigue Performance

Dynamic load-bearing capacity: The 7049 aluminum alloy exhibits excellent performance when subjected to repeated loads (such as aerodynamic loads encountered during flight, impacts from landing gear, etc.). This is because the microscopic structure of the material can effectively disperse stress, reducing the probability of fatigue damage.

Durability: Due to its good fatigue performance, 7049 aluminum profiles can maintain high strength over long-term use, reducing the risk of failure due to material fatigue. This durability is crucial in structural components of aircraft, especially in critical areas that require high safety standards.

Reliability: The fatigue performance of 7049 aluminum alloy allows it to maintain good operational status even under extreme conditions, enhancing the overall safety and reliability of the aircraft. This makes the 7049 aluminum profile more widely applicable in the aerospace field, particularly in critical structural components.

7049 aerospace aluminum profiles chemical composition

| Element | Composition % |

| Al | 90 |

| Zn | 5.6-6.4 |

| Mg | 1.9-2.6 |

| Cu | 0.06-0.16 |

| Mn | 0.03 |

| Cr | 0.04 |

7049 aerospace aluminum profiles mechanical property

| Tensile strength | generally between 520 MPa and 570 MPa |

| Yield strength | generally between 450 MPa and 510 MPa |

| Elongation | generally between 7% and 10% |

| Hardness | generally between 140 HB and 160 HB |

| Impact toughness | generally between 30 J/cm2 to 40 J/cm2 |

| Fatigue life | generally between 10, 000 and 100, 000 cycles |

7049 T73511 Aircraft Aluminum Profiles

7049 T73511 aluminum alloy is a high-strength, heat-treatable alloy primarily used in aerospace applications. The T73511 condition indicates that the alloy has undergone solution heat treatment, artificial aging, and further stabilization. This process enhances its mechanical properties, including yield strength, ultimate tensile strength, and toughness. The alloy is known for its excellent fatigue resistance and outstanding stress corrosion cracking resistance, making it suitable for demanding environments.

Applications of 7049 T73511 Aluminum Profiles in Aviation

- Fuselage components: Used in the construction of aircraft fuselages, the high strength-to-weight ratio is critical for structural integrity and performance.

- Wing structures: Used in ribs and spars, providing necessary support while reducing weight.

- Landing gear components: Used in landing gear components due to its strength and resistance to stress deformation.

7049 T76511 Aircraft Aluminum Profiles

7049 T76511 aluminum alloy is also a high-strength, heat-treatable alloy that has enhanced properties due to its special processing techniques. The T76511 condition indicates that it has undergone solution heat treatment followed by over-aging. Compared to other conditions, this improves stress corrosion resistance and further enhances toughness and ductility.

Applications of 7049 T76511 Aluminum Profiles in Aviation

- Fuselage structures: Commonly used in the manufacture of fuselage structures that require outstanding strength and durability.

- Load-bearing components: Used in critical load-bearing components, such as beams and frames, where weight reduction is crucial for overall aircraft efficiency.

- Wing and tail components: Used in wing and tail components to ensure structural integrity and performance during flight.

Specific Applications of 7049 Aluminum Profiles in the Aviation Field

1. Aerospace Structural Components

7049 aluminum alloy is widely used in critical structural components of aircraft due to its excellent mechanical properties.

Wing support structures

Wings are important load-bearing parts of an aircraft, needing to withstand significant aerodynamic forces and operational loads. The high strength and rigidity of 7049 aluminum alloy make it an ideal material for wing spars and skins. This aluminum alloy can effectively resist bending and twisting, ensuring stability and safety of the wings during flight.

Fuselage frames

7049 aluminum alloy is widely used in aircraft fuselage frames to ensure strength and rigidity while reducing overall weight. Due to its high strength characteristics, this aluminum alloy can provide better durability during long flights, reducing maintenance costs.

2. Landing Gear Components

7049 aluminum alloy plays a vital role in aircraft landing gear components due to its excellent strength and toughness.

Main landing gear beams

Main landing gear beams need to provide strong support and stability to withstand gravity and dynamic loads during landing and takeoff. The high strength characteristics of 7049 aluminum alloy allow it to effectively dissipate and absorb impact loads, enhancing the reliability of the landing gear.

Struts

The struts of the landing gear bear significant impact loads during aircraft landing, and using 7049 aluminum alloy can effectively improve their compressive and bending capacities, ensuring a safe landing.

3. Seats and Window and Door Frames

7049 aluminum profiles are also widely used in various components and accessories of aircraft.

Seat frames

7049 aluminum alloy is used to manufacture the frames of passenger seats, where the design must meet strict strength requirements while reducing weight to enhance passenger comfort and overall maneuverability. This aluminum alloy provides necessary support, ensuring safety during flight.

Window and door frames

7049 aluminum profiles are used for the frames of aircraft windows and doors, offering good strength and corrosion resistance. These frames ensure safety and sealing while effectively reducing noise, enhancing the passenger experience.

4. Structural Frameworks

7049 aluminum profiles also play an important role in the internal structure of aircraft.

Cargo hold structures

7049 aluminum alloy is used in the supporting structures of cargo holds, capable of bearing the weight of the cargo while considering the dynamic loads of the cargo. This aluminum alloy can effectively prevent structural fatigue and increase the service life of the cargo hold.

Interior frames

7049 aluminum profiles play a crucial role in the frameworks of interior decorations and functional layouts of aircraft. These frames need to balance aesthetics and practicality, and the good machinability of 7049 aluminum alloy allows it to be precisely manufactured into various shapes, meeting the demands of aerospace design.