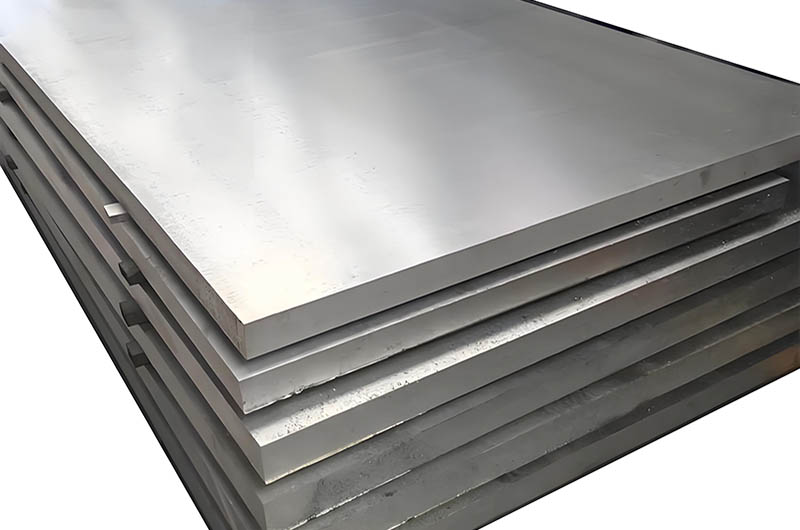

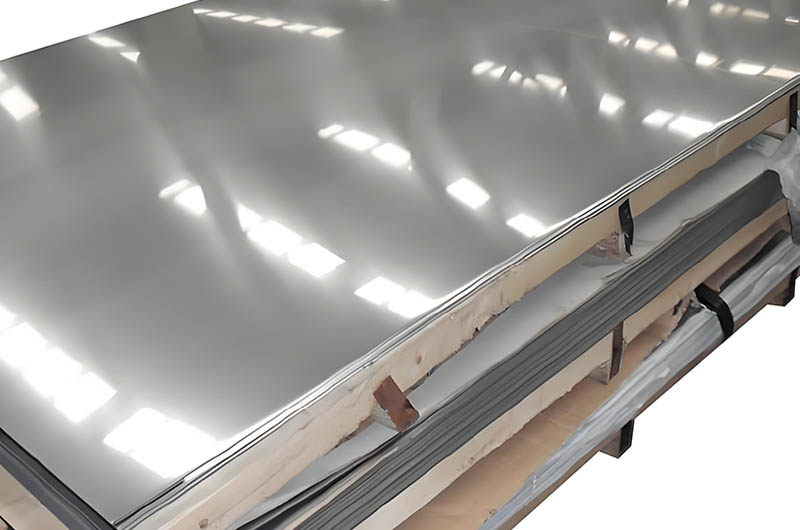

7068 Aircraft Aluminum Plate Sheet

7068 aluminum plate is a high-performance, heat-treatable aluminum-zinc alloy in the 7000 series. 7068 was initially developed for demanding applications such as aerospace, defense, and high-stress industrial components, standing out for its excellent strength-to-weight ratio. In many cases, its tensile properties can rival certain steels while still benefiting from the inherent lightweight nature of aluminum.

7068 aluminum plate is an ideal choice when high strength is prioritized without excessive weight.

7068 aluminum alloy is mainly used in applications requiring strict performance under pressure. It is one of the strongest aluminum alloys available, with its strength typically exceeding the famous 7075 alloy. Its availability is not as common as 7075, and it is typically used in specialized high-performance applications.

Common temper: T6 (solution heat-treated and artificially aged) or T7 (over-aged to enhance stress corrosion resistance).

7068 aluminum plate is suitable for high performance applications

- High strength: Yield strength significantly exceeds that of more traditional alloys like 7075.

- Excellent performance: Including outstanding fatigue strength and corrosion resistance.

- Lightweight structure: 7068 aluminum is highly suitable for aerospace and military applications, where weight reduction is critical.

- Versatility: Offers various temper options to optimize performance to meet specific environmental or mechanical demands.

This unique combination of properties makes 7068 aluminum plate the material of choice for applications requiring the highest strength-to-weight ratio and reliable performance under harsh conditions.

Standards and Specifications for Aluminum 7068 Sheet / Plate

| Specification | Details |

| AMS | AMS 4331 (for bars/forgings; sheet specifications may differ). |

| ASTM | B209 (for sheet/plate form). |

| Military | MIL-DTL-46027 (for specific applications). |

| Thickness | 0.3 mm to 120 mm |

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc. |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. |

| Finish | Cold rolled sheet (CR), Hot rolled plate (HR), brush, mirror, etc. |

| Hardness | T6/T6511 |

Properties of 7068 Aircraft Aluminum Plate Sheet

| Properties | Description |

| Strength | The strength of 7068 aircraft aluminum plate sheet is about 10% higher than that of 7075-T6 aluminum alloy, making it one of the highest strength aluminum alloys on the market. This property makes 7068 aluminum alloy particularly suitable for aerospace structural components that experience high loads and extreme environmental conditions. Its excellent strength makes it valuable in applications that require high load-bearing capacity, such as aircraft fuselage, wings, and other critical structural parts. |

| Fatigue Resistance | 7068 aircraft aluminum plate sheet has excellent fatigue resistance, making it especially suitable for cyclic load applications. In the aerospace field, components are often subjected to repetitive stress and vibration, and 7068 aluminum alloy effectively resists these repeated pressures, extending the component's service life. Its fatigue resistance is crucial in applications that require high reliability, such as aircraft fuselage frames and engine support components. |

| Machinability | 7068 aircraft aluminum plate sheet has moderate machinability. Due to its high strength, carbide tools are required during machining. Although it is more difficult to process, its outstanding performance and strength still make it the material of choice for many high-end applications. For parts requiring precise cutting and complex machining, 7068 aluminum alloy provides an ideal performance foundation. |

| Weldability | 7068 aircraft aluminum plate sheet has poor weldability and is prone to cracking. Due to its high strength and compositional characteristics, welding may lead to embrittlement of the material, making it generally unsuitable for joining by conventional welding methods. To avoid welding defects, 7068 aluminum alloy is typically connected by mechanical fasteners or adhesives, which are common joining methods in aerospace and high-end manufacturing fields. |

| Corrosion Resistance | 7068 aircraft aluminum plate sheet has lower corrosion resistance than 6061 aluminum alloy, so additional protection is required when used in harsh environments. To ensure its durability in humid or corrosive environments, the surface of 7068 aluminum alloy is usually coated or anodized. These surface treatments not only enhance its corrosion resistance but also improve its appearance and wear resistance, ensuring its reliability during long-term use. |

| Lightweight | Like most aluminum alloys, 7068 aircraft aluminum plate sheet is lightweight. This property makes it particularly valuable in applications where weight reduction is essential. In aerospace, reducing the weight of an aircraft is crucial for improving fuel efficiency and flight performance. The lightweight characteristics of 7068 aluminum alloy help designers optimize structural designs while maintaining strength and performance, achieving the best weight-efficiency ratio. |

7068 Aluminum Heat Treatment

- T6511: Provides maximum static strength, making it ideal for critical load-bearing parts.

- T76/T76511: Offers a balance by slightly lowering strength to enhance fracture toughness and stress corrosion cracking resistance.

- T6: Provides high strength, but may reduce ductility compared to other states.

Applications of 7068 Aircraft Aluminum Plate Sheet

7068 aluminum alloy was initially used in military weapons due to its high strength and is regarded as the strongest commercial aluminum. This means it can be used in applications that require an exceptional strength-to-weight ratio, such as connecting rods, high-performance suspension components, and demanding aerospace parts.

Applications: It is used in industries that require high-performance components, such as aerospace, military, and automotive industries. Examples include firearm components, high-performance bicycles, and aircraft structural parts.

| Application Area | Description |

| Aerospace | 7068 aluminum plate is widely used in the aerospace field, primarily for aircraft structural components such as fuselage and wing parts. Due to its outstanding strength-to-weight ratio, it can reduce structural weight while maintaining strength, which is crucial for improving flight efficiency and reducing fuel consumption. The high strength and excellent fatigue resistance of 7068 aluminum plate allow it to withstand extreme working conditions and repeated stresses while maintaining a long service life. It is especially suitable for structural parts of high-performance aircraft, enhancing the overall performance of the aircraft. |

| Automotive and Motorsports | In the automotive and motorsports industries, 7068 aluminum plate is primarily used for high-performance engine components, such as valve bodies, connecting rods, and other critical parts. For racing and high-performance vehicles, strength and weight reduction are crucial, and the excellent strength and lightweight characteristics of 7068 aluminum alloy can effectively enhance vehicle acceleration, handling, and fuel efficiency. Its high strength ensures that these components can withstand high loads during high-speed operations, while the reduced weight improves the vehicle's overall dynamic performance, contributing to top competition results in motorsport. |

| Medical Equipment | In the medical equipment field, 7068 aluminum plate is ideal for prosthetics and other medical applications due to its excellent biocompatibility and durability. With its outstanding mechanical properties and corrosion resistance, 7068 aluminum alloy is used to manufacture prosthetic parts, surgical instruments, and other medical devices that require high strength and long-lasting durability. Its high strength ensures the reliability of medical equipment under extreme working conditions, while its good biocompatibility ensures safe contact with the human body, making it widely used in various fields of the medical industry. |

| Recreational Equipment | 7068 aluminum plate is also widely used in the recreational equipment field, particularly in bicycles, mountaineering gear, and other high-pressure, lightweight applications. For these types of equipment, strength and lightweight properties are key requirements, and 7068 aluminum alloy provides the perfect solution. Its high strength and low density allow these sports equipment to maintain strength while reducing weight when subjected to intense pressure and external forces, improving the equipment's durability and performance. It is favored by extreme sports enthusiasts and professional athletes. |

7068 aluminum alloy is a specialized material used in demanding applications where high strength and low weight are crucial.

Aluminium 7068 Properties

| Density | 2.85 mg/cm³ |

| Melting point | 476-635 ℃ |

| Tensile strength | 641 MPa |

| Yield strength | 590 MPa |

| Elongation | 8% |

7068 Aircraft Aluminum Plate Sheet Chemical Composition

| Al | Zn | Mg | Cu | Fe | Zr | Si | Mn | Ti | Cr | Other(each) | Other(total) |

| 85.43 | 8.3 | 3 | 2.4 | 0.15 | 0.15 | 0.12 | 0.1 | 0.1 | 0.05 | 0.05 | 0.15 |

7068 Aluminum Plate Mechanical Properties

| Mechanical Properties | Metric | English | Comments |

| Hardness, Brinel | 190 | 190 | 500 kg, 10 mm |

| Tensile Strength, Ultimate | 710 MPa @Diameter 12.7 mm | 103000 psi @Diameter 0.500 in | |

| Tensile Strength, Yield | 683 MPa @Diameter 12.7 mm | 99100 psi @Diameter 0.500 in | |

| Elongation at Break | 9.0 % @Diameter 12.7 mm | 9.0 % @Diameter 0.500 in | 4D |

| Fracture Toughness | 16.5 MPa-m½ | 15.0 ksi-in½ | T-L |

| 27.5 MPa-m½ | 25.0 ksi-in½ | L-T | |

| Shear Strength | 365 MPa | 53000 psi |

7068 Aluminum Plate Thermal Properties

| Thermal Properties | Metric | English | Comments |

| CTE, linear | 23.4 µm/m-°C @Temperature 20.0 - 100 °C | 13.0 µin/in-°F @Temperature 68.0 - 212 °F | |

| Specific Heat Capacity | 1.05 J/g-°C @Temperature 100 °C | 0.250 BTU/lb-°F @Temperature 212 °F | |

| Thermal Conductivity | 190 W/m-K | 1320 BTU-in/hr-ft²-°F | |

| Melting Point | 476 - 635 °C | 889 - 1180 °F | |

| Solidus | 476 °C | 889 °F | |

| Liquidus | 635 °C | 1180 °F |

7068 Aluminum Plate Corrosion Resistance

| Property | Description |

| General Corrosion Resistance | 7068 Aluminum Plate has moderate corrosion resistance. Under normal environmental conditions, it can resist a certain degree of corrosion, such as humidity and mild chemical exposure. However, in high-humidity, salt, or acidic environments, its corrosion resistance is not as strong as some lower-strength aluminum alloys, such as 5000 series alloys. Additionally, due to 7068's high strength from the 7XXX series, its copper and zinc content is higher, making it more prone to localized corrosion, such as pitting and crevice corrosion, in harsh environments. Therefore, extra protective measures are needed when used in corrosive environments. |

| Stress Corrosion Cracking (SCC) Impact | 7068 Aluminum Plate is susceptible to stress corrosion cracking (SCC) in high-stress environments, particularly in moist, high-temperature, or chloride-containing environments. SCC mainly occurs in areas under tensile stress, such as the fastener regions or high-load parts in aerospace structures. This phenomenon can lead to reduced material strength and potentially cause crack propagation, compromising the overall safety of the structure. Therefore, when designing components using 7068 aluminum alloy, special attention must be given to stress distribution to avoid local stress concentrations and reduce the risk of SCC. |

| Protective Measures | When exposed to harsh environments, it is recommended to take protective measures to enhance the corrosion resistance of 7068 Aluminum Plate. Common methods include anodizing, coating, or composite protection techniques. For example, anodizing aluminum can create a dense oxide film on the material surface, significantly enhancing its corrosion resistance; painting or epoxy coatings provide an additional physical barrier to prevent the penetration of corrosive agents. Furthermore, in some applications, composite coatings (such as anodizing with sealing or coating combinations) can offer more durable protection, thereby extending the service life of 7068 aluminum alloy in severe environments. |

Comparison of 7068 Aluminum with Other Alloys

| Comparison | Description |

| Compared to 7075 | 7068 Aluminum has higher strength than 7075, with its tensile strength being about 10-15% higher. This high-strength property makes 7068 more suitable for extreme load environments, such as aerospace and military applications. However, 7068's corrosion resistance is slightly inferior to 7075, especially in humid or salt environments. Therefore, in applications that require high strength but also have some corrosion resistance demands, 7075 is still a more balanced choice, while 7068 is more suited for applications where high strength is the primary concern. |

| Compared to 7050 | 7050 Aluminum is known for its excellent stress corrosion cracking (SCC) resistance, whereas 7068 performs weaker in this regard. In cases requiring high corrosion resistance and good fatigue life, such as the main structural components of aircraft and landing gear, 7050 may be a more suitable choice. However, 7068's advantage lies in its higher peak strength, making it suitable for applications that require extreme strength, such as high-load precision machinery and protective equipment. |

| Compared to 6061 | 7068 Aluminum far surpasses 6061 in mechanical strength, being approximately 2.5 times stronger. In contrast, 6061 offers better machinability, weldability, and corrosion resistance, which is why it is widely used in structural components, shipbuilding, and the automotive industry. However, when the application scenario demands extreme strength, such as in high-performance military or aerospace structures, 7068 is the superior choice. |

Limitations of 7068 aluminum

- Prone to stress corrosion cracking (SCC) in humid/salty environments.

- Requires protective coatings for outdoor use.

- Limited availability compared to 6061 or 7075.

Manufacturing considerations for 7068 aluminum

- Machining: Use sharp tools, high speed, and cooling fluids to control heat.

- Forming: Limited cold workability; hot forming is better.

- Surface treatment: Anodizing or Alodine coating can improve corrosion resistance.

7068 aluminum plate is the material of choice for engineers prioritizing strength and weight reduction in critical applications. While its corrosion resistance and manufacturing challenges require careful planning, its unparalleled mechanical properties demonstrate its application in aerospace, defense, and advanced industrial design. Proper heat treatment and surface protection are key to maximizing its service life.

Frequently Asked Questions

| Question | Answer |

| What is 7068 aluminum used for? | 7068 aluminum alloy is used in applications that require high strength and low weight, such as aerospace components, military equipment, sports equipment, automotive parts, and structural applications in various industries. |

| What is the difference between 7068 and 6061? | 7068 aluminum alloy has significantly higher strength, with a tensile strength 2.5 times greater than that of 6061. Additionally, 7068 belongs to the 7000 series and is primarily zinc-based, while 6061 belongs to the 6000 series and contains magnesium and silicon. This makes 7068 suitable for high-stress applications, while 6061 is more commonly used for general purposes. |

| What is the difference between 7068 and 7075 aluminum? | 7068 aluminum is known for its high tensile strength and excellent performance under pressure, making it one of the strongest aluminum alloys. 7075 aluminum is also very strong, but it offers a better balance between machinability and durability. Both alloys are corrosion-resistant and suitable for high-performance applications. However, when maximum strength is critical, 7068 is typically preferred. |