7075 Aerospace Aluminum Bar Rod

7075 aluminum bar is one of the representative commercial high-strength aluminum alloys and belongs to the Al-Zn-Mg-Cu system of super-hard aluminum materials.

7075 aluminum bar is a high-strength, lightweight material mainly composed of aluminum, zinc, magnesium, and copper. It is known for its excellent strength-to-weight ratio and is widely used in applications where durability and weight reduction are critical.

7075 aluminum belongs to the 7000 series and is one of the strongest aluminum alloys available. Its primary alloying element is zinc, along with small amounts of magnesium and copper. Due to its high strength-to-weight ratio and good fatigue resistance, it is commonly used in aerospace and high-performance applications.

7075 aerospace aluminum is a high-strength, heat-treatable aluminum alloy known for its excellent mechanical properties and corrosion resistance. It is typically used in aerospace applications, as well as in the military and automotive industries.

To improve corrosion resistance, 7075 aluminum is often anodized or coated with a chromate conversion layer. This makes it more suitable for outdoor applications or harsh environments.

Features of 7075 Aerospace Aluminum Bar Rod

- High Strength: 7075 aluminum is one of the strongest aluminum alloys, with tensile strength depending on the temper condition.

- Fatigue Resistance: It has good fatigue resistance, making it suitable for applications subjected to cyclic loads.

- Machinability: 7075 alloy has good machinability, but due to its high strength, it is more difficult to machine compared to other aluminum alloys.

- Corrosion Resistance: Although its corrosion resistance is better than some other high-strength alloys, it is still prone to corrosion and may require protective coatings in harsh environments.

- Weldability: 7075 is generally not weldable because welding significantly reduces its strength. Alternative joining methods such as rivets or adhesives are commonly used.

Sizes and Forms of 7075 Aerospace Aluminum Bar Rod Available

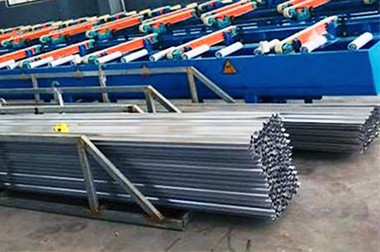

7075 aluminum bars and rods are typically available in various diameters, lengths, and shapes (such as round, square, or flat).

T651: Similar to T6, this condition involves stretching to relieve stress, which helps reduce internal stress and improve dimensional stability.

The T6 condition is achieved through solution heat treatment followed by artificial aging. This increases strength but slightly reduces ductility.

| Products | Product Image | Description |

| 7075 T6 Aluminum Bar Rod |

|

7075 T6 aluminum is a high-strength alloy known for its excellent mechanical properties. The "T6" designation indicates that the material has been solution heat-treated and artificially aged, resulting in enhanced strength and hardness. This type of bar rod is commonly used in structural applications, aerospace components, and high-stress environments due to its superior strength-to-weight ratio. |

| 7075 T651 Aluminum Bar Rod |

|

Similar to the T6 designation, the "T651" indicates that the aluminum has gone through a solution heat treatment and is then stress-relieved by stretching to eliminate internal stresses. This process improves the dimensional stability and mechanical properties of the material. The 7075 T651 aluminum bar rod is ideal for applications requiring high strength, such as aerospace, military, and automotive components. |

| 7075 Aerospace Al Extruded Bar |

|

This refers to 7075 aluminum that has been extruded into bar form, specifically designed for aerospace applications. The extrusion process involves forcing the aluminum through a die to create a specific cross-sectional shape. This results in a product with excellent mechanical properties, uniformity, and surface finish, making it suitable for structural components in aircraft and other aerospace vehicles. |

| 7075 Aerospace Aluminum Forged Bar |

|

This type of bar is made from 7075 aluminum that has been forged, a process that involves shaping the metal through compressive forces. Forging enhances the strength and toughness of the aluminum, making it ideal for high-stress applications in aerospace. The resulting bar has a fine-grained structure, which provides improved mechanical properties over cast materials. |

| 7075 Aluminum Flat Bar |

|

7075 Aluminum Flat Bar is a high-strength alloy that is commonly used in applications requiring excellent stress resistance and lightweight properties. Known for its superb mechanical properties, it is typically used in aerospace, military, and high-performance engineering sectors. The flat bar form allows easy machining and is ideal for structural applications such as frame components and brackets. |

| 7075 T6 Aluminum Round Bar |

|

7075 T6 Aluminum Round Bar is an incredibly strong and durable product, widely used in aerospace and military applications where strength-to-weight ratio is critical. The T6 temper provides superior strength and resistance to stress and fatigue. Its round shape makes it suitable for various machined parts, shafts, and components requiring high tensile strength and good corrosion resistance. |

| Aluminum Square Bar 7075-T651 |

|

Aluminum Square Bar 7075-T651 combines the outstanding mechanical properties of 7075 aluminum with a square profile for versatile machining and structural applications. The T651 temper ensures the bar has excellent stress resistance and toughness, making it perfect for applications in aircraft frames, high-strength fittings, and other demanding engineering sectors. |

| Aluminum Round Bar 7075 |

|

Aluminum Round Bar 7075 is renowned for its superior strength and fatigue resistance, making it ideal for heavy-duty applications in the aerospace, automotive, and military industries. This round bar offers excellent machinability and is often used to create precise, high-stress components such as shafts, pins, and rods that require excellent mechanical properties and durability. |

| 7075 Cold Finish Aluminum Bar |

|

7075 Cold Finish Aluminum Bar is a cold-finished product that provides better surface finish and dimensional precision compared to standard hot-rolled bars. It combines the high strength of the 7075 alloy with a smooth surface, making it suitable for machining into precise parts like shafts, brackets, and gears for aerospace, military, and other critical applications. |

| 7075 Aluminum Hex Bar |

|

7075 Aluminum Hex Bar is a versatile product with the same high strength and toughness as the standard 7075 alloy, but in a hexagonal shape. This shape makes it ideal for applications where space constraints or the need for a specific geometry are important. It is often used for custom machined parts and components that require exceptional mechanical properties, especially in high-performance industries like aerospace and defense. |

7075 chemical composition of aluminum rods bar for aerospace

| Chemical composition limits | |||||||||||

| Weight% | Al | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other Each | Others Total |

| Alloy 7075 min | Rem | - | - | 1.2 | - | 2.1 | 0.18 | 5.1 | - | - | - |

| Alloy 7075 max | Rem | 0.4 | 0.5 | 2 | 0.3 | 2.9 | 0.28 | 6.1 | 0.2 | 0.05 | 0.15 |

AMS 7075 aluminum alloy bar rod physical performance parameters

| Standard Product | Tensile strength | Yield strength | Elongation |

| AMS 4122 7075-T6 extruded aluminum rod | 524 MPa | 455 MPa | 0.11 |

| AMS 4123 7075-T651 cold-draw aluminum rod | 572 MPa | 503 MPa | 0.11 |

| AMS 4124 7075-T7351 cold-draw aluminum rod | 524 MPa | 455 MPa | 0.11 |

| AMS 4186 7075-TF cold-draw aluminum rod | 524 MPa | 455 MPa | 0.11 |

| AMS 4187 7075-0 cold-draw aluminum rod | 324 MPa | 124 MPa | 0.16 |

7075 aluminum is difficult to weld using traditional fusion techniques but is typically joined in aerospace applications through friction stir welding or riveting. Due to its high strength, it is easier to machine than to weld.

7075 Aluminum Bar Heat Treatment and Tempering

- T6: Solution heat treatment (480°C), quenching, and artificial aging (120°C/24h) to achieve peak strength.

- T651: Stress relieving by stretching; improves dimensional stability.

- T73: Sacrifices some strength to enhance stress corrosion resistance.

7075 Aluminum Bar Corrosion Resistance

| Corrosion Resistance Characteristics | Description |

| Lower than 6061; requires protective treatment in harsh environments | The corrosion resistance of 7075 aluminum bar is lower than that of 6061 aluminum bar, especially in marine, chemical, or humid environments where it is prone to corrosion. Therefore, when used in these harsh environments, protective treatments such as anodizing or coating are required to enhance its surface corrosion resistance. |

| T73 temper improves stress corrosion resistance, but sacrifices strength | After T73 tempering, the stress corrosion resistance of 7075 aluminum bar is significantly improved, making it suitable for high-temperature, high-humidity, or corrosive environments. However, T73 tempering causes a reduction in strength, so it is important to choose the appropriate temper based on the specific application. |

7075 Aluminum Bar Standards and Certifications

- AMS 4047: Aerospace material specification.

- ASTM B221: Standard for extruded bars.

7075 Aluminum Bar Advantages and Limitations

Advantages of 7075 Aluminum Bar

| Advantages | Description |

| Excellent strength-to-weight ratio | 7075 aluminum bar has extremely high tensile strength, more than 1.5 times that of 6061 aluminum bar, making it widely used in aerospace, military, and high-load structural components. Its high strength ensures greater load-bearing capacity at the same weight, making it ideal for high-performance, high-strength lightweight designs. |

| Very suitable for high-performance applications | 7075 aluminum bar has high tensile strength and good fatigue strength, making it ideal for aerospace, aviation, and military applications. Its excellent mechanical properties make it the material of choice for high-performance components that need to withstand extreme loads, commonly used in aircraft fuselage frames, landing gear, and racing car components. |

Limitations of 7075 Aluminum Bar

- Poor weldability.

- Higher cost compared to 6061.

- Moderate corrosion resistance requiring coatings.

Applications of 7075 Aluminum Bar

Applications of 7075 Aluminum Bar in Aerospace

7075 aluminum bar is widely used in the aerospace industry due to its high strength, good fatigue strength, and corrosion resistance. It is used in the manufacture of primary structural components of aircraft, such as wing frames, fuselage frames, elevators, rudders, and other parts subjected to large loads. The superior mechanical properties of 7075 aluminum alloy play a critical role in ensuring the reliability and safety of aircraft in high-stress environments.

Applications of 7075 Aluminum Bar in Aircraft Framework and High-Strength Components

In the manufacturing of aircraft frameworks and high-strength components, 7075 aluminum bar is an ideal material. Its high strength and low density make it the material of choice for aircraft frame parts, engine mounts, flight control system components, and other load-bearing parts. 7075 aluminum alloy can maintain structural integrity under extreme operating conditions, especially when subjected to high dynamic loads and fatigue stresses during flight.

7075 aluminum is widely used in aircraft structures such as wings, fuselage frames, and structural components that require a high strength-to-weight ratio.

- Wings: Since wings endure significant loads and need to minimize weight, the high strength and low weight of 7075 aluminum make it an ideal choice for wing frames and skins.

- Fuselage frames: The use of 7075 alloy in fuselage frames provides the necessary strength and stiffness to support the structural integrity of the entire aircraft.

- Landing gear: Landing gear structures need to withstand heavy impacts and loads, and the high strength characteristics of 7075 aluminum make it perform excellently in these applications.

- High-strength structural components: 7075 aluminum is also commonly used in other key aircraft parts, such as transmission systems and connectors, where the optimal balance between weight and strength is required.

Applications of 7075 Aluminum Bar in Mold Processing

7075 aluminum bar also has significant applications in mold processing. Its excellent hardness and wear resistance make it very suitable for the manufacturing of high-precision mold components, particularly those requiring high temperature and high-pressure resistance. 7075 aluminum alloy can withstand mechanical and thermal stresses generated during mold manufacturing, and is commonly used in injection molds, die-casting molds, and other manufacturing mold components, providing good stability and long service life.

Applications of 7075 Aluminum Bar in Mechanical Equipment

The applications of 7075 aluminum bar in mechanical equipment mainly involve high-strength, lightweight, and easy-to-process components. Due to its superior mechanical properties, 7075 aluminum alloy is widely used in high-strength load-bearing components for mechanical equipment, such as brackets, transmission systems, and robotic arms. These components require tensile strength and fatigue resistance, and 7075 aluminum alloy meets these requirements, helping to improve performance and extend the service life of mechanical equipment.

Comparison of 7075 Aluminum with Other Related Aluminum Alloys

How does 7075 aluminum compare to 6061 aluminum alloy?

Compared to 6061, 7075 has approximately 85% higher tensile strength, but its corrosion resistance and weldability are lower.

Which is better suited for use at room temperature?

Room Temperature Use

7075 aluminum bar, due to its high strength, is suitable for bearing large mechanical loads at room temperature, and is commonly used for structural and load-bearing components. However, 6061 aluminum bar, with better corrosion resistance and machinability, is often used for structural designs and multipurpose components, particularly in outdoor and marine environments. Overall, 6061 aluminum bar may be more versatile in room temperature applications, especially in cases with higher corrosion resistance requirements.

Which performs better at high temperatures?

High-Temperature Performance

The performance of 7075 aluminum bar may degrade at high temperatures, especially in environments above 150°C. Its strength decreases more rapidly at high temperatures, making it less suitable for applications exposed to prolonged high temperatures. In contrast, 6061 aluminum bar performs more stably at high temperatures. It has better heat resistance, can withstand higher temperatures, and is easier to achieve good mechanical properties during heat treatment. Therefore, 6061 aluminum bar performs better at high temperatures and is more suitable for use in a wider temperature range.

7075 aluminum bar is ideal for applications requiring high strength and lightweight design, but for room temperature use and high-temperature stability, 6061 aluminum bar may be the better choice, especially when corrosion resistance and weldability are important.

How to Choose and Use 7075 Aluminum Bar?

Choose the Right Specification of 7075 Aluminum Bar Based on Requirements

The selection of 7075 aluminum bar should be based on the specific application requirements.

Choose the appropriate specification based on the required strength, corrosion resistance, machinability, and temperature resistance.

- If the application requires high tensile strength (such as in aerospace or military components), 7075 aluminum bar in T6 or T7 temper (high-strength temper) is the ideal choice.

- For environments that require longer service life and better corrosion resistance, it is recommended to choose 7075 aluminum bar that has been anodized to enhance its surface corrosion resistance.

Note on the Temperature Range for Using 7075 Aluminum Bar

The operating temperature of 7075 aluminum bar should be kept below 150°C, especially when exposed to high-temperature environments for long periods. At high temperatures, the strength of 7075 aluminum bar will decrease, making it unsuitable for high-temperature structural components. If using 7075 aluminum bar in a high-temperature environment, ensure that it stays within the suitable temperature range to avoid performance degradation due to excessive heat.

How to Ensure the Quality of 7075 Aluminum Bar Material?

To ensure the quality of 7075 aluminum bar,

- Choose certified suppliers to ensure that the 7075 aluminum bars meet international or industry standards (such as ASTM B211, AMS-QQ-A-250/12, etc.).

- Check the material certificate, chemical composition, and mechanical performance report to confirm that the aluminum bar meets the required specifications and strength requirements.

- Physical performance tests, such as tensile strength and elongation, can be conducted before actual use to ensure the quality of the 7075 aluminum bar meets application needs.

- For particularly stringent applications, it is recommended to request a material quality inspection report from the supplier to ensure it is defect-free and uniform.

What to Pay Attention to When Processing 7075 Aluminum Bar?

7075 Aluminum Bar Processing Characteristics

- Excellent machinability, suitable for CNC processing.

- Poor weldability, requires special processing techniques.

- Can be anodized to enhance surface corrosion resistance.

7075 Aluminum Bar Manufacturing Precautions

- Moderate corrosion resistance, surface protective treatment is required for marine environments.

- Highly sensitive to stress corrosion, it is recommended to use T73 or T7351 post-aging treatment to improve resistance.

- Machining: Use sharp, carbide tools with cooling functions; machining is excellent but harder than 6061.

- Welding: Not recommended due to cracking risks; mechanical fastening is preferred.

- Surface treatment: Anodizing or coating (e.g., aluminum anodizing) to enhance corrosion resistance.

7075 aluminum bar is best suited for applications requiring high strength and lightweight characteristics, such as aerospace and military use. Proper selection of heat treatment and surface treatment is crucial to reducing corrosion risks. Although manufacturing requires specialized techniques, its performance makes it a reliable choice for critical high-stress environments.

7075 aluminum bar is a premium material choice for applications that require a combination of strength and low weight. Proper treatment and processing are essential to fully utilize its properties.

You may also be interested in the following

-

2024 7075 Aerospace Aluminum for Door Components

2024 and 7075 high-strength aluminum alloys are used in aircraft door components to ensure durability, deformation resistance, and safety.

-

2024, 7075, and 7475 Aerospace Aluminum for Wing Skins

2024, 7075, and 7475 combinations exhibit excellent strength and fatigue resistance, making them suitable for wing skins to withstand deformation under stress.

-

2024 7075 Aerospace Aluminum for Fuselage Frames

2024, 7075, and 7475 aluminum alloys are essential materials in aerospace engineering, particularly for fuselage frames. Their unique properties enable engineers to select the most appropriate alloy based on specific requirements for strength, weight, corrosion resistance, and fatigue performance.

-

2024 7050 7075 Aerospace Aluminum for Horizontal Tail Fittings

Alloys 2024, 7050, and 7075 provide the necessary strength and stiffness for horizontal tail components of aircraft, ensuring reliable control surface performance.