7075 Aluminum Flat Bar

7075 aluminum flat bars are high-strength aluminum alloy products primarily composed of zinc as the main alloying element. These bars are renowned for their excellent strength-to-weight ratio and are commonly used in applications where both strength and lightweight characteristics are essential.

7075 Aluminum Flat Bar Specifications

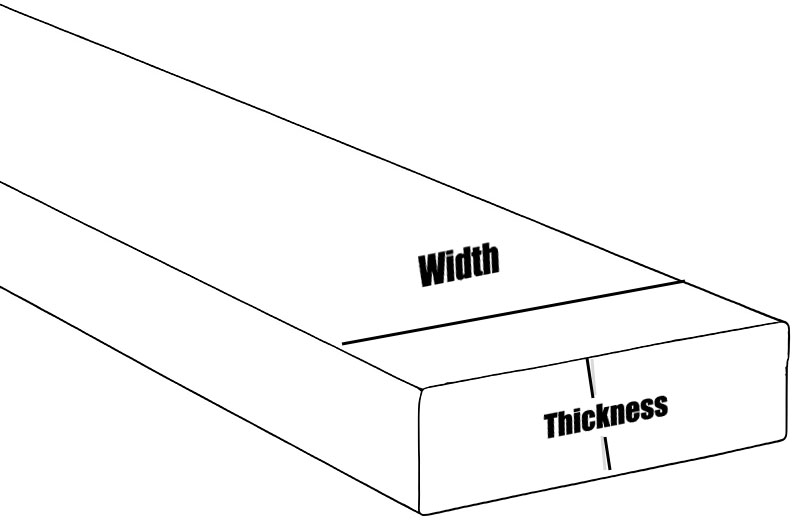

| Category | Specification |

| Thickness | 1/8 inch (0.125 inch) to 2 inches (common), custom sizes available |

| Width | 1/2 inch to 12 inches |

| Length | Standard 12-foot bars, customizable upon request |

| Tolerance | Compliant with ASTM B209 |

| Surface Treatment Options | Mill finish (extruded), anodized, powder-coated (custom colors), polished, or brushed finish |

| Material | 7075 Aluminum Flat Bar |

| Temper | T6/T651 Cold Finished, T6/T651 Extruded, T7351 Cold Finished |

| Supply Form | Available in full-size bars and custom-cut lengths |

Haomei 7075 Aluminum Flat Bar Stock Size List

As a trusted manufacturer of 7075 aluminum, Haomei Aluminum specializes in producing high-quality ASTM/AMS-certified flat bars with an excellent strength-to-weight ratio. Our 7075-T6/T651 alloy flat bars offer outstanding stress resistance and corrosion protection, making them ideal for aerospace frames, military equipment components, and high-performance automotive parts.

We offer custom sizes and precision machining services. Our ISO 9001-certified production ensures consistent quality and provides technical support and bulk order discounts for OEM partners. Request material certification sheets and machining specifications now.

7075 Aluminum Flat Bar Stock Informations

- Thickness: 0.25", 0.375", 0.5", 0.625", 0.75", 1", 1.25", 1.5", 2", 2.5", 4"

- Width: 2", 3", 1", 1.5", 0.75", 2.5", 4", 4.5", 6", 3.75", 3.5", 1.25", 5"

- Temper: T6, T651, T73511, T7351, T6511

- Production Method: Cold Finish, Extruded

| Description | Thickness | Width | Temper | Production Method |

| 0.25" x 2" Aluminum Flat Bar 7075-T6-Cold Finish | 0.25" | 2" | T6 | Cold Finish |

| 0.25" x 3" Aluminum Flat Bar 7075-T6-Cold Finish | 0.25" | 3" | T6 | Cold Finish |

| 0.25" x 1" Aluminum Flat Bar 7075-T6-Cold Finish | 0.25" | 1" | T6 | Cold Finish |

| 0.25" x 1.5" Aluminum Flat Bar 7075-T6-Cold Finish | 0.25" | 1.5" | T6 | Cold Finish |

| 0.375" x 3" Aluminum Flat Bar 7075-T651-Cold Finish | 0.375" | 3" | T651 | Cold Finish |

| 0.375" x 1" Aluminum Flat Bar 7075-T6-Cold Finish | 0.375" | 1" | T6 | Cold Finish |

| 0.375" x 1.5" Aluminum Flat Bar 7075-T6-Cold Finish | 0.375" | 1.5" | T6 | Cold Finish |

| 0.375" x 2" Aluminum Flat Bar 7075-T6-Cold Finish | 0.375" | 2" | T6 | Cold Finish |

| 0.5" x 1" Aluminum Flat Bar 7075-T651-Cold Finish | 0.5" | 1" | T651 | Cold Finish |

| 0.5" x 1.5" Aluminum Flat Bar 7075-T651-Cold Finish | 0.5" | 1.5" | T651 | Cold Finish |

| 0.5" x 2" Aluminum Flat Bar 7075-T651-Cold Finish | 0.5" | 2" | T651 | Cold Finish |

| 0.5" x 0.75" Aluminum Flat Bar 7075-T651-Cold Finish | 0.5" | 0.75" | T651 | Cold Finish |

| 0.5" x 1.5" Aluminum Flat Bar 7075-T73511-Extruded | 0.5" | 1.5" | T73511 | Extruded |

| 0.5" x 2.5" Aluminum Flat Bar 7075-T651-Cold Finish | 0.5" | 2.5" | T651 | Cold Finish |

| 0.5" x 3" Aluminum Flat Bar 7075-T651-Cold Finish | 0.5" | 3" | T651 | Cold Finish |

| 0.5" x 4" Aluminum Flat Bar 7075-T651-Cold Finish | 0.5" | 4" | T651 | Cold Finish |

| 0.5" x 1" Aluminum Flat Bar 7075-T7351-Cold Finish | 0.5" | 1" | T7351 | Cold Finish |

| 0.5" x 2" Aluminum Flat Bar 7075-T651-Extruded | 0.5" | 2" | T651 | Extruded |

| 0.625" x 1" Aluminum Flat Bar 7075-T73511-Extruded | 0.625" | 1" | T73511 | Extruded |

| 0.75" x 2" Aluminum Flat Bar 7075-T651-Cold Finish | 0.75" | 2" | T651 | Cold Finish |

| 0.75" x 2.5" Aluminum Flat Bar 7075-T651-Cold Finish | 0.75" | 2.5" | T651 | Cold Finish |

| 0.75" x 3" Aluminum Flat Bar 7075-T651-Cold Finish | 0.75" | 3" | T651 | Cold Finish |

| 0.75" x 1.5" Aluminum Flat Bar 7075-T73511-Extruded | 0.75" | 1.5" | T73511 | Extruded |

| 0.75" x 1" Aluminum Flat Bar 7075-T73511-Extruded | 0.75" | 1" | T73511 | Extruded |

| 0.75" x 1" Aluminum Flat Bar 7075-T651-Cold Finish | 0.75" | 1" | T651 | Cold Finish |

| 0.75" x 1.5" Aluminum Flat Bar 7075-T651-Cold Finish | 0.75" | 1.5" | T651 | Cold Finish |

| 0.75" x 1" Aluminum Flat Bar 7075-T6511-Extruded | 0.75" | 1" | T6511 | Extruded |

| 0.75" x 4.5" Aluminum Flat Bar 7075-T7351-Cold Finish | 0.75" | 4.5" | T7351 | Cold Finish |

| 0.75" x 6" Aluminum Flat Bar 7075-T7351-Cold Finish | 0.75" | 6" | T7351 | Cold Finish |

| 0.75" x 3.75" Aluminum Flat Bar 7075-T7351-Cold Finish | 0.75" | 3.75" | T7351 | Cold Finish |

| 0.75" x 2" Aluminum Flat Bar 7075-T7351-Cold Finish | 0.75" | 2" | T7351 | Cold Finish |

| 0.75" x 4" Aluminum Flat Bar 7075-T7351-Cold Finish | 0.75" | 4" | T7351 | Cold Finish |

| 0.75" x 1" Aluminum Flat Bar 7075-T7351-Cold Finish | 0.75" | 1" | T7351 | Cold Finish |

| 0.75" x 1.5" Aluminum Flat Bar 7075-T7351 | 0.75" | 1.5" | T7351 | Extruded |

| 0.75" x 3" Aluminum Flat Bar 7075-T651-Extruded | 0.75" | 3" | T651 | Extruded |

| 1" x 2" Aluminum Flat Bar 7075-T651-Cold Finish | 1" | 2" | T651 | Cold Finish |

| 1" x 3" Aluminum Flat Bar 7075-T651-Cold Finish | 1" | 3" | T651 | Cold Finish |

| 1" x 4" Aluminum Flat Bar 7075-T651-Cold Finish | 1" | 4" | T651 | Cold Finish |

| 1" x 1.5" Aluminum Flat Bar 7075-T651-Cold Finish | 1" | 1.5" | T651 | Cold Finish |

| 1" x 1.5" Aluminum Flat Bar 7075-T73511-Extruded | 1" | 1.5" | T73511 | Extruded |

| 1" x 2" Aluminum Flat Bar 7075-T73511-Extruded | 1" | 2" | T73511 | Extruded |

| 1" x 2.5" Aluminum Flat Bar 7075-T651-Cold Finish | 1" | 2.5" | T651 | Cold Finish |

| 1" x 3" Aluminum Flat Bar 7075-T7351-Cold Finish | 1" | 3" | T7351 | Cold Finish |

| 1" x 3.5" Aluminum Flat Bar 7075-T7351-Cold Finish | 1" | 3.5" | T7351 | Cold Finish |

| 1" x 1.25" Aluminum Flat Bar 7075-T7351-Cold Finish | 1" | 1.25" | T7351 | Cold Finish |

| 1" x 1.25" Aluminum Flat Bar 7075-T651-Cold Finish | 1" | 1.25" | T651 | Cold Finish |

| 1" x 3" Aluminum Flat Bar 7075-T6511-Extruded | 1" | 3" | T6511 | Extruded |

| 1.25" x 4" Aluminum Flat Bar 7075-T651-Cold Finish | 1.25" | 4" | T651 | Cold Finish |

| 1.25" x 2" Aluminum Flat Bar 7075-T73511-Extruded | 1.25" | 2" | T73511 | Extruded |

| 1.25" x 3" Aluminum Flat Bar 7075-T651-Cold Finish | 1.25" | 3" | T651 | Cold Finish |

| 1.25" x 2" Aluminum Flat Bar 7075-T651-Cold Finish | 1.25" | 2" | T651 | Cold Finish |

| 1.25" x 2.5" Aluminum Flat Bar 7075-T651-Cold Finish | 1.25" | 2.5" | T651 | Cold Finish |

| 1.25" x 3" Aluminum Flat Bar 7075-T7351-Cold Finish | 1.25" | 3" | T7351 | Cold Finish |

| 1.25" x 2.5" Aluminum Flat Bar 7075-T7351-Cold Finish | 1.25" | 2.5" | T7351 | Cold Finish |

| 1.25" x 3.5" Aluminum Flat Bar 7075-T6511-Extruded | 1.25" | 3.5" | T6511 | Extruded |

| 1.25" x 1.5" Aluminum Flat Bar 7075-T7351-Cold Finish | 1.25" | 1.5" | T7351 | Cold Finish |

| 1.5" x 3" Aluminum Flat Bar 7075-T73511-Extruded | 1.5" | 3" | T73511 | Extruded |

| 1.5" x 2" Aluminum Flat Bar 7075-T651-Cold Finish | 1.5" | 2" | T651 | Cold Finish |

| 1.5" x 3" Aluminum Flat Bar 7075-T651-Cold Finish | 1.5" | 3" | T651 | Cold Finish |

| 1.5" x 4" Aluminum Flat Bar 7075-T651-Cold Finish | 1.5" | 4" | T651 | Cold Finish |

| 1.5" x 6" Aluminum Flat Bar 7075-T651-Cold Finish | 1.5" | 6" | T651 | Cold Finish |

| 1.5" x 4.5" Aluminum Flat Bar 7075-T651-Cold Finish | 1.5" | 4.5" | T651 | Cold Finish |

| 1.5" x 2.5" Aluminum Flat Bar 7075-T7351-Cold Finish | 1.5" | 2.5" | T7351 | Cold Finish |

| 1.5" x 2.5" Aluminum Flat Bar 7075-T73511-Extruded | 1.5" | 2.5" | T73511 | Extruded |

| 1.5" x 3" Aluminum Flat Bar 7075-T6511-Extruded | 1.5" | 3" | T6511 | Extruded |

| 2" x 3" Aluminum Flat Bar 7075-T651-Cold Finish | 2" | 3" | T651 | Cold Finish |

| 2" x 4" Aluminum Flat Bar 7075-T73511-Extruded | 2" | 4" | T73511 | Extruded |

| 2" x 6" Aluminum Flat Bar 7075-T73511-Extruded | 2" | 6" | T73511 | Extruded |

| 2" x 3" Aluminum Flat Bar 7075-T73511-Extruded | 2" | 3" | T73511 | Extruded |

| 2" x 6" Aluminum Flat Bar 7075-T651-Cold Finish | 2" | 6" | T651 | Cold Finish |

| 2" x 4" Aluminum Flat Bar 7075-T651 | 2" | 4" | T651 | Extruded |

| 2.5" x 4" Aluminum Flat Bar 7075-T73511-Extruded | 2.5" | 4" | T73511 | Extruded |

| 2.5" x 3" Aluminum Flat Bar 7075-T651-Cold Finish | 2.5" | 3" | T651 | Cold Finish |

| 2.5" x 4" Aluminum Flat Bar 7075-T651-Cold Finish | 2.5" | 4" | T651 | Cold Finish |

| 2.5" x 6" Aluminum Flat Bar 7075-T7351-Cold Finish | 2.5" | 6" | T7351 | Cold Finish |

| 2.5" x 6" Aluminum Flat Bar 7075-T6511-Extruded | 2.5" | 6" | T6511 | Extruded |

| 4" x 5" Aluminum Flat Bar 7075-T6511- Extruded | 4" | 5" | T6511 | Extruded |

| 4" x 5" Aluminum Flat Bar 7075-T73511-Extruded | 4" | 5" | T73511 | Extruded |

| 4" x 6" Aluminum Flat Bar 7075-T7351-Cold Finish | 4" | 6" | T7351 | Cold Finish |

7075 Aluminum Flat Bar Common Tempers and Characteristics

- 7075 T6: Subjected to solution heat treatment and artificial aging, providing peak strength.

- 7075 T651: Similar to T6, but with additional stress relief processing to improve machinability.

- 7075 T73/T7351: Over-aged to enhance resistance to stress corrosion cracking while maintaining strength.

7075 Aluminum Flat Bar Chemical Composition

| Typical Chemical Composition % | ||||||||||

| Weight % | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Each | Total |

| Minimum | 1.20 | 2.10 | 0.18 | 5.10 | ||||||

| Maximum | 0.40 | 0.50 | 2.00 | 0.30 | 2.90 | 0.28 | 6.10 | 0.20 | 0.05 | 0.15 |

7075 Aluminum Flat Bar Mechanical Properties

| Typical Mechanical Properties | ||||||

| Temper | Tensile | Hardness | ||||

| Ultimate | Yield | Elongation | Brinell | |||

| KSI | MPA | KSI | MPA | % | ||

| T6, T651 | 83 | 572 | 73 | 503 | 11 | 150 |

| T73, T7351 | 73 | 503 | 63 | 434 | 13 | N/A |

7075 Aluminum Flat Bar Applications

| Application | Description |

| Aerospace | 7075 aluminum flat bars are widely used in the aerospace industry for manufacturing various structural components. Their exceptional strength and good corrosion resistance make them ideal for producing wing beams, fuselage frames, and tail structures. The material's low weight without compromising strength ensures stable performance under high load and high-stress environments, guaranteeing structural safety and long-term durability of the aircraft. |

| Military | In military applications, 7075 aluminum flat bars are extensively used to produce high-strength and lightweight components, such as structural elements of armored vehicles and other tactical vehicles. Their excellent strength-to-weight ratio enhances armor protection while maintaining a low weight, contributing to improved mobility and durability of military equipment. Additionally, their corrosion resistance ensures reliable performance in harsh environments. |

| Automotive | 7075 aluminum flat bars are widely applied in the high-performance automotive sector, particularly for manufacturing frames and suspension components. They effectively reduce weight while enhancing structural strength. These components must withstand significant impact forces, vibrations, and high-speed pressures. The exceptional strength and light weight of 7075 aluminum make it an ideal choice for racing and performance vehicles, improving handling and safety. |

| Industrial | In industrial applications, 7075 aluminum flat bars are commonly used in high-stress machinery, fixtures, and tooling. Due to their superior strength, they provide reliable support for demanding mechanical equipment. Their lightweight properties also facilitate ease of operation and reduce equipment loads. Additionally, the stability and durability of 7075 aluminum flat bars make them a preferred choice for precision industrial manufacturing. |

| Sports | 7075 aluminum flat bars are extensively used in sports equipment, including bicycle frames and climbing gear, where high strength is crucial. Their lightweight and durable characteristics allow athletes to reduce unnecessary weight while ensuring durability and stability during activities. The material's excellent impact absorption capability ensures that sports equipment can withstand external forces during high-intensity use, providing safety for athletes. |

7075 Aluminum Flat Bar Manufacturing and Processing

- Weldability: Poor; prone to cracking (use 4043 filler if necessary).

- Machinability: Excellent (comparable to free-machining brass).

- Forming: Best performed in the annealed (O temper) condition.

- Heat Treatment: T6 temper (solution heat treated and artificially aged).

Standards and Certifications

- ASTM B209 (Standard Specification).

- AMS 4045 (Aerospace Material Specification).

- MIL-A-22771 (Military Specification).

Comparison Between 7075 Aluminum Flat Bar and 6061 Aluminum

- Strength: 7075 is approximately 30% stronger than 6061-T6.

- Corrosion Resistance: 6061 offers better corrosion resistance than 7075 in most environments.

- Cost: Due to its alloy composition, 7075 is generally more expensive.

Considerations:

While 7075 aluminum exhibits excellent mechanical properties, its corrosion resistance is lower compared to other aluminum alloys like 6061. Additionally, it is not easy to weld; welding can reduce its strength, making it generally not recommended for welded applications. However, it is machinable, though its hardness requires the use of appropriate tools for effective machining.

You may also be interested in the following

-

2024 7075 Aerospace Aluminum for Door Components

2024 and 7075 high-strength aluminum alloys are used in aircraft door components to ensure durability, deformation resistance, and safety.

-

2024, 7075, and 7475 Aerospace Aluminum for Wing Skins

2024, 7075, and 7475 combinations exhibit excellent strength and fatigue resistance, making them suitable for wing skins to withstand deformation under stress.

-

2024 7075 Aerospace Aluminum for Fuselage Frames

2024, 7075, and 7475 aluminum alloys are essential materials in aerospace engineering, particularly for fuselage frames. Their unique properties enable engineers to select the most appropriate alloy based on specific requirements for strength, weight, corrosion resistance, and fatigue performance.

-

2024 7050 7075 Aerospace Aluminum for Horizontal Tail Fittings

Alloys 2024, 7050, and 7075 provide the necessary strength and stiffness for horizontal tail components of aircraft, ensuring reliable control surface performance.