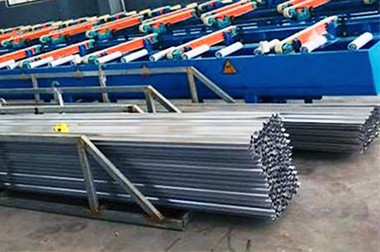

7075 T73 Round Bar

7075-T73 aluminum round bar is a high-strength aerospace-grade alloy known for its exceptional mechanical properties and resistance to stress corrosion cracking.

Made from 7075 aluminum, this aerospace-grade alloy is renowned for its excellent strength-to-weight ratio. In the T73 temper, the material undergoes over-aging compared to the T6 temper, significantly enhancing its stress corrosion cracking resistance while maintaining high strength, albeit with slightly reduced tensile and yield strength.

7075-T73 aluminum round bar is a premium aerospace-grade alloy designed for demanding applications requiring an outstanding strength-to-weight ratio and enhanced stress corrosion resistance. As a leading manufacturer, we provide precision-manufactured round bars that meet ASTM B211, AMS 4122, and AMS 4124 standards, ensuring reliability in critical environments.

7075-T73 Round Bar Informations

7075-T73 is an Aerospace Aluminum Alloy

7075-T73 round bar is a high-performance aerospace aluminum alloy widely used in the aviation and aerospace industries for its exceptional properties. After undergoing the T73 heat treatment process, this alloy round bar exhibits excellent corrosion resistance and stable mechanical performance, making it ideal for aircraft structural components and critical parts exposed to high loads and harsh environments.

High Strength, High Toughness, Excellent Corrosion Resistance

| Property | Description |

| High Strength | 7075-T73 round bar possesses extremely high strength. After precise heat treatment and machining, its tensile strength and yield strength are among the highest in aluminum alloys. Its high-strength characteristics make it widely used in aircraft fuselages, wing spars, landing gear components, and other parts that endure significant stress. |

| Excellent Toughness | 7075-T73 round bar offers exceptional toughness, ensuring it does not easily fracture under external impact or vibration. Its high toughness makes it the preferred material for aircraft structural components, military equipment, and high-performance sports equipment that require excellent impact resistance. |

| Good Corrosion Resistance | 7075-T73 round bar also demonstrates good corrosion resistance, particularly excelling in marine or high-humidity environments. It is widely used in aircraft fuselage skins, door components, and offshore operation equipment, significantly extending the service life of these applications. |

Cold Treated and Forged Alloy

7075-T73 round bar undergoes cold treatment and forging processes, ensuring a uniform internal structure without defects while further enhancing its mechanical properties. The cold treatment and forging process provide excellent dimensional accuracy and surface quality, making it extensively used in the manufacturing of aerospace components requiring high precision and reliability.

7075 T73 Round Bar Technical Specifications

| Parameter | Description |

| Standards | ASTM B211, AMS 4122, AMS 4124, AMS QQ-A-225/9 |

| Available Sizes | Diameter ranging from 0.25 inches to 1.5 inches, with custom lengths up to 144 inches |

| Density | 2.8–3.0 g/cm³ |

| Melting Point | 890–1180°F (477–638°C) |

| Production Process | Round bar manufactured using cold processing techniques |

| Dimensional Tolerance | Cut length typically ±0.125 inches |

| Surface Finish | Smooth surface finish suitable for precision applications |

7075 T73 Aluminum Round Bar Material Properties

- Machinability: Fine grain structure enables deep drilling and high-precision machining, enhances tool wear resistance, and provides excellent thread rolling performance.

- Heat Treatment Condition: T73 is a specialized heat treatment process that balances material strength and stress corrosion resistance, offering superior overall performance compared to some other conditions (e.g., T6).

Advantages of 7075 T73 Aluminum Round Bar

- Stress Corrosion Resistance: Superior to T6 temper, making it highly suitable for corrosion-prone environments.

- High Strength-to-Weight Ratio: Comparable to low-carbon steel, but 33% lighter, ideal for weight-sensitive applications.

- Machinability: Rated at approximately 70% of free-cutting brass, allowing for efficient machining processes.

7075 T73 Aluminum Round Bar Alloy Composition and Mechanical Properties

7075 aluminum typically contains approximately 5.1-6.1% zinc, 2.1-2.9% magnesium, and 1.2-2.0% copper, with trace amounts of other elements. In the T73 (or the closely related T7351) temper, the typical mechanical properties are as follows:

- Ultimate Tensile Strength: Approximately 73, 000 psi

- Yield Strength: Approximately 63, 000 psi

- Elongation: Approximately 13%

These properties make the 7075-T73 alloy an ideal choice for components that experience high stress while requiring durability and enhanced corrosion resistance.

7075 T73 Aluminum Comparison with Other Tempers

| Property | T73/T7351 | T6/T651 |

| Corrosion Resistance | High | Moderate |

| Ultimate Strength | 73 ksi | 83 ksi |

| Primary Use Case | Corrosive environments | Maximum strength applications |

| Elongation | 13% | 11% |

Comparison between 7075 T73 and 6061 Materials

What is the difference in strength?

7075 T73 aluminum round bar is significantly stronger than 6061 aluminum round bar. The tensile strength and yield strength of 7075 T73 are much higher than 6061, maintaining excellent structural stability even under large loads and stress conditions. Therefore, it is more suitable for applications in aerospace and other fields that require high-strength materials.

How do they compare in corrosion resistance?

7075 T73 aluminum round bar has better corrosion resistance than 6061 aluminum round bar. After T73 heat treatment, the corrosion resistance of 7075 aluminum is significantly improved, particularly in humid or marine environments, demonstrating strong resistance to corrosion. This makes it an ideal material for aerospace, offshore equipment, and other applications that require high corrosion resistance.

Applications of 7075-T73 Round Bar

Aerospace Applications

Aerospace: Structural frameworks, accessories, and missile components.

| Application Area | Description |

| Structural Frameworks | 7075-T73 round bar is widely used in structural frameworks in aerospace. With its excellent strength and good toughness, it can withstand the enormous stresses that aircraft experience during flight, ensuring the stability and safety of critical parts such as fuselage structures and wings. |

| Aerospace Accessory Manufacturing | 7075-T73 round bar performs exceptionally well in aerospace accessory manufacturing. Due to its outstanding mechanical properties and corrosion resistance, it is used in the production of high-load components such as landing gear parts, cabin door hinges, and connectors, meeting the stringent durability and reliability requirements of aircraft. |

What other industries use it?

7075-T73 round bar is widely used in industries requiring lightweight and durable components:

- Military: Armor components, rifle parts, and defense equipment.

- Automotive: High-performance racing components and suspension systems.

- Industrial Machinery: Gears, shafts, and tools, high-stress structural components.

- High-performance sports equipment (e.g., bicycle frames)

Purchasing Suggestions and Considerations for 7075-T73 Round Bar

What factors should be considered when purchasing?

When purchasing 7075-T73 round bar, it is important to consider its application scenarios and performance requirements. Due to its high strength and excellent corrosion resistance, its suitability should be determined based on the specific environment of use. For example, aerospace, military, or high-load structural components require high strength and durability. Additionally, consider the qualifications of the supplier and the product's certification standards, such as ASTM B211, AMS 4122, etc., to ensure material quality and reliability.

What parameters should be understood before purchasing?

Before purchasing 7075-T73 round bar, key parameters should be understood, including diameter, length, density, melting point, strength indicators (such as tensile strength and yield strength), and tolerance standards. Dimensional accuracy and surface finish are crucial to the performance and machining quality of the final product. Furthermore, confirm the production processes (such as cold working) and heat treatment state (T73) to ensure its performance meets design and manufacturing requirements.

Why choose Haomei Aluminum as your 7075 aluminum round bar supplier?

Our cold-drawn, extruded, and forged 7075 aluminum round bars are manufactured in our factory with strict tolerance width, then cut to the required length, making them an ideal choice for critical components. From aircraft frames to bicycle parts, trust us as your reliable high-quality 7075 aluminum supplier.

7075-T73 round bar offers a balanced combination of strength, durability, and improved corrosion resistance, superior to peak-aged temper such as T6. Its controlled over-aging (T73 temper) makes it a reliable choice for applications requiring high mechanical performance and long-term durability in harsh environments.

You may also be interested in the following

-

2024 7075 Aerospace Aluminum for Door Components

2024 and 7075 high-strength aluminum alloys are used in aircraft door components to ensure durability, deformation resistance, and safety.

-

2024, 7075, and 7475 Aerospace Aluminum for Wing Skins

2024, 7075, and 7475 combinations exhibit excellent strength and fatigue resistance, making them suitable for wing skins to withstand deformation under stress.

-

2024 7075 Aerospace Aluminum for Fuselage Frames

2024, 7075, and 7475 aluminum alloys are essential materials in aerospace engineering, particularly for fuselage frames. Their unique properties enable engineers to select the most appropriate alloy based on specific requirements for strength, weight, corrosion resistance, and fatigue performance.

-

2024 7050 7075 Aerospace Aluminum for Horizontal Tail Fittings

Alloys 2024, 7050, and 7075 provide the necessary strength and stiffness for horizontal tail components of aircraft, ensuring reliable control surface performance.