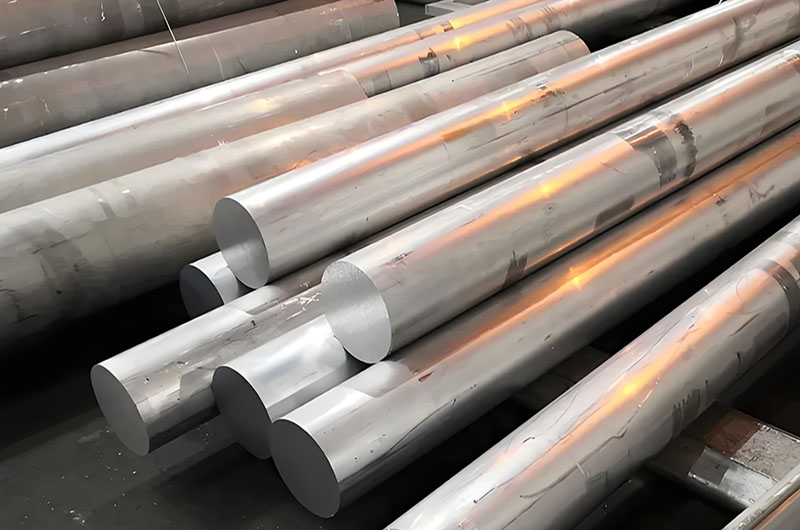

7075-t6 Aluminum Round Bar

7075 T6 aluminum round bar is a high-performance cold-worked product made from one of the strongest aluminum alloys available. It is primarily composed of aluminum, with zinc as the major alloying element (typically 5.1-6.1%), along with magnesium (2.1-2.9%), copper (1.2-2.0%), and trace amounts of other elements such as chromium and titanium.

The "T6" designation indicates that the bar has undergone solution heat treatment and artificial aging to achieve peak strength, while the T651 variant includes a controlled stretching step to release internal stresses.

Compared to other states, the "T6" process increases strength and hardness, but it may reduce ductility.

7075-T6 Aluminum Round Bar Specifications

| Parameter | Specification Information |

| Diameter Range | 0.25 inches (6 mm) to 12 inches (300 mm) or customized |

| Length | Typically 12 feet (3.66 meters), can be cut to size |

| Standards and Certifications | ASTM B211 (Aluminum Rod Standard Specification) |

| AMS 4048 (Aerospace Material Specification) | |

| Surface Treatment | Rolled finish (extruded condition) |

| Anodizing, painting, or coating to enhance corrosion resistance |

7075-T6 Aluminum Round Bar Corrosion Resistance

Due to its copper content, it is more susceptible to stress corrosion cracking compared to 6061. Outdoor/marine applications typically require protective coatings.

Corrosion Resistance of 7075-T6 Aluminum Round Bar

The corrosion resistance of 7075-T6 aluminum round bar is relatively low due to its high copper content. While the addition of copper improves the strength and hardness of the material, it also reduces the corrosion resistance of the aluminum alloy. Especially in humid or corrosive environments, the 7075-T6 aluminum round bar is prone to corrosion reactions. Therefore, its corrosion resistance should be carefully considered when selecting application scenarios.

Stress Corrosion Cracking (SCC) of 7075-T6 Aluminum Round Bar in Harsh Environments

7075-T6 aluminum round bar is susceptible to stress corrosion cracking (SCC) in harsh environments. Due to its high-strength properties, when exposed to high stress and corrosive media, such as in marine or industrial atmospheres, microscopic cracks may form within the alloy and gradually propagate. This phenomenon significantly reduces the material's service life and structural reliability.

Protection for 7075-T6 Aluminum Round Bar in Outdoor and Marine Environments

7075-T6 aluminum round bar typically requires additional protective coatings when used in outdoor or marine environments to enhance its corrosion resistance. Common protective measures include anodizing, electroplating, and applying epoxy resin or polyurethane coatings. These coatings not only effectively isolate the material from moisture and salt corrosion but also extend its service life, ensuring excellent mechanical properties in harsh environments.

Haomei 7075 t6 Aluminum Round Bar Stock Size List

| Description | Diameter | Temper | Production Method |

| 0.25" Aluminum Round Bar 7075-T6-Cold Finish | 0.25" | T6 | Cold Finish |

| 0.3125" Aluminum Round Bar 7075-T6 | 0.3125" | T6 | Cold Finish |

| 0.375" Aluminum Round Bar 7075-T6-Cold Finish | 0.375" | T6 | Cold Finish |

| 0.5" Aluminum Round Bar 7075-T651-Cold Finish | 0.5" | T651 | Cold Finish |

| 0.5625" Aluminum Round Bar 7075-T651-Cold Finish | 0.5625" | T651 | Cold Finish |

| 0.625" Aluminum Round Bar 7075-T651-Cold Finish | 0.625" | T651 | Cold Finish |

| 0.75" Aluminum Round Bar 7075-T651-Cold Finish | 0.75" | T651 | Cold Finish |

| 0.875" Aluminum Round Bar 7075-T651-Cold Finish | 0.875" | T651 | Cold Finish |

| 1" Aluminum Round Bar 7075-T651-Cold Finish | 1" | T651 | Cold Finish |

| 1.125" Aluminum Round Bar 7075-T651-Cold Finish | 1.125" | T651 | Cold Finish |

| 1.25" Aluminum Round Bar 7075-T651-Cold Finish | 1.25" | T651 | Cold Finish |

| 1.375" Aluminum Round Bar 7075-T651-Cold Finish | 1.375" | T651 | Cold Finish |

| 1.5" Aluminum Round Bar 7075-T651-Cold Finish | 1.5" | T651 | Cold Finish |

| 1.625" Aluminum Round Bar 7075-T651-Cold Finish | 1.625" | T651 | Cold Finish |

| 1.75" Aluminum Round Bar 7075-T651-Cold Finish | 1.75" | T651 | Cold Finish |

| 1.875" Aluminum Round Bar 7075-T651-Cold Finish | 1.875" | T651 | Cold Finish |

| 2" Aluminum Round Bar 7075-T651-Cold Finish | 2" | T651 | Cold Finish |

| 2.125" Aluminum Round Bar 7075-T651-Cold Finish | 2.125" | T651 | Cold Finish |

| 2.25" Aluminum Round Bar 7075-T651-Cold Finish | 2.25" | T651 | Cold Finish |

| 2.5" Aluminum Round Bar 7075-T651-Cold Finish | 2.5" | T651 | Cold Finish |

| 2.625" Aluminum Round Bar 7075-T651-Cold Finish | 2.625" | T651 | Cold Finish |

| 2.75" Aluminum Round Bar 7075-T651-Cold Finish | 2.75" | T651 | Cold Finish |

| 3" Aluminum Round Bar 7075-T651-Cold Finish | 3" | T651 | Cold Finish |

| 3.25" Aluminum Round Bar 7075-T651-Cold Finish | 3.25" | T651 | Cold Finish |

| 3.5" Aluminum Round Bar 7075-T651-Cold Finish | 3.5" | T651 | Cold Finish |

| 3.75" Aluminum Round Bar 7075-T651-Cold Finish | 3.75" | T651 | Cold Finish |

| 4" Aluminum Round Bar 7075-T651-Cold Finish | 4" | T651 | Cold Finish |

| 4.25" Aluminum Round Bar 7075-T651-Cold Finish | 4.25" | T651 | Cold Finish |

| 4.5" Aluminum Round Bar 7075-T651-Cold Finish | 4.5" | T651 | Cold Finish |

| 4.75" Aluminum Round Bar 7075-T651-Cold Finish | 4.75" | T651 | Cold Finish |

| 5" Aluminum Round Bar 7075-T651-Cold Finish | 5" | T651 | Cold Finish |

| 5.5" Aluminum Round Bar 7075-T651-Cold Finish | 5.5" | T651 | Cold Finish |

| 6" Aluminum Round Bar 7075-T651-Cold Finish | 6" | T651 | Cold Finish |

| 7" Aluminum Round Bar 7075-T651-Cold finish | 7" | T651 | Cold Finish |

| 7.5" Aluminum Round Bar 7075-T651-Cold finish | 7.5" | T651 | Cold Finish |

| 8" Aluminum Round Bar 7075-T651 Cold Finish | 8" | T651 | Cold Finish |

7075-T6 Aluminum Round Bar Machining and Manufacturing

| Machining and Manufacturing Characteristics | Description |

| Machinability | 7075-T6 aluminum round bar has excellent machinability, producing clean chips during processes such as turning, milling, and drilling. This characteristic helps improve machining precision and surface quality. However, due to the higher hardness of 7075-T6 aluminum round bar, it requires more stringent tool requirements. Typically, sharp carbide tools and appropriate cutting fluids are needed to reduce tool wear and increase machining efficiency. |

| Weldability | The weldability of 7075-T6 aluminum round bar is poor, primarily due to its high copper content, which makes it prone to cracking and weld seam embrittlement during welding. In cases where joining is necessary, welding is generally not recommended. Instead, 7075-T6 aluminum round bar is more commonly joined using mechanical fasteners (such as bolts and screws) or structural adhesives to ensure the integrity and long-term reliability of the structure. |

| Formability | The formability of 7075-T6 aluminum round bar in the T6 condition is limited. As the T6 condition is a high-strength state achieved by solution heat treatment and artificial aging, the material has lower plasticity, making it difficult to perform complex bending or stretching. If significant forming is required, 7075 aluminum round bar in the annealed condition (O-temper) is typically used for preliminary forming, followed by heat treatment to restore the material's mechanical properties. |

7075-T6 Aluminum Round Bar Applications

Due to its excellent strength-to-weight ratio, 7075-T6 aluminum round bar is typically used in demanding aerospace, high-performance automotive, and military applications. It is also suitable for precision-machined parts, such as gears, shafts, and structural components, where lightweight and high strength are crucial.

| Application Area | Description |

| Aerospace | 7075-T6 aluminum round bar is widely used in the aerospace industry, primarily in critical load-bearing components such as aircraft wing beams, landing gear, and fuselage frames. These components endure significant dynamic loads and environmental pressures during flight, so the material must have high strength, lightweight properties, and fatigue resistance. With its exceptional mechanical properties and good structural stability, 7075-T6 aluminum round bar is the preferred material for aerospace structural parts. |

| Automotive Industry | In the automotive industry, 7075-T6 aluminum round bar is commonly used to manufacture chassis, suspension systems, and engine components for high-performance racing cars. These components need to balance lightweight and strength to enhance vehicle handling and acceleration performance. The high strength-to-weight ratio of 7075-T6 aluminum round bar makes it an ideal choice for achieving ultimate performance in the automotive field while effectively reducing overall vehicle weight. |

| Defense and Military | 7075-T6 aluminum round bar also plays an important role in the defense and military fields, commonly used in firearm components such as receivers and barrels, as well as some armored structures. Due to its excellent strength and hardness, it can withstand high-impact and high-pressure loads while maintaining material stability. Its fatigue resistance and wear resistance ensure the reliability and long service life of weaponry in harsh environments. |

| Industrial Manufacturing | In industrial manufacturing, 7075-T6 aluminum round bar is commonly used to manufacture shafts, gears, high-stress fasteners, and support components in marine engineering. These parts are often subjected to high loads and complex environments, requiring materials with excellent mechanical properties and some corrosion resistance. While the corrosion resistance of 7075-T6 aluminum round bar is not as high as some anti-corrosion alloys, its performance in harsh environments can be significantly improved with surface treatments. |

| Sports | 7075-T6 aluminum round bar is widely used in the sports industry to manufacture bicycle frames and climbing equipment. Due to its high strength and lightweight characteristics, bicycle frames reduce weight while maintaining strength, improving riding efficiency. In climbing equipment, the material's toughness and impact resistance ensure athlete safety. 7075-T6 aluminum round bar has become the material of choice for many outdoor sports equipment manufacturers. |

7075 t6 Aluminum Round Bar Limitations

- Higher cost compared to 6061.

- Not recommended for unprotected welded structures or highly corrosive environments.

7075 t6 Aluminum Round Bar vs 6061-T6 Comparison

- Strength: 7075-T6 is approximately 30% stronger.

- Corrosion resistance: 6061-T6 outperforms 7075.

- Machinability: Both are good, but 7075 requires stronger tools.

Key Considerations

- Avoid use in chloride-rich environments without protection.

- Complex machined parts may require stress-relief treatments to prevent cracking.

7075-T6 aluminum round bar is best suited for applications requiring a high strength-to-weight ratio, where cost and corrosion resistance are secondary considerations.

The material meets various industry standards (e.g., ASTM B211, AMS-QQ-A-225/9, AMS-4122), ensuring its reliability in critical applications.

You may also be interested in the following

-

2024 7075 Aerospace Aluminum for Door Components

2024 and 7075 high-strength aluminum alloys are used in aircraft door components to ensure durability, deformation resistance, and safety.

-

2024, 7075, and 7475 Aerospace Aluminum for Wing Skins

2024, 7075, and 7475 combinations exhibit excellent strength and fatigue resistance, making them suitable for wing skins to withstand deformation under stress.

-

2024 7075 Aerospace Aluminum for Fuselage Frames

2024, 7075, and 7475 aluminum alloys are essential materials in aerospace engineering, particularly for fuselage frames. Their unique properties enable engineers to select the most appropriate alloy based on specific requirements for strength, weight, corrosion resistance, and fatigue performance.

-

2024 7050 7075 Aerospace Aluminum for Horizontal Tail Fittings

Alloys 2024, 7050, and 7075 provide the necessary strength and stiffness for horizontal tail components of aircraft, ensuring reliable control surface performance.