7175 Aerospace Aluminum Profiles Extrusions

7175 aluminum alloy profiles have become an important material in the aerospace field due to their excellent performance, particularly in strength and fatigue resistance.

7175 aluminum profiles are a high-strength aluminum alloy primarily composed of aluminum, zinc, magnesium, and copper, offering outstanding mechanical properties and corrosion resistance.

Characteristics of 7175 Aerospace Aluminum Profiles Extrusions

- 1. High Strength: The 7175 aluminum alloy exhibits excellent tensile and yield strength, making it suitable for applications that require high load-bearing capacity.

- 2. Good Fatigue Resistance: In the dynamic load environment of aircraft, 7175 aluminum alloy demonstrates good fatigue performance, reducing the risk of failure due to fatigue.

- 3. Lightweight: Compared to traditional materials, 7175 aluminum alloy offers an excellent strength-to-weight ratio, helping aircraft achieve higher fuel efficiency and greater payload capacity.

- 4. Weldability: Although the welding performance of 7175 aluminum alloy is relatively poor, structural connections can be achieved through other methods such as riveting.

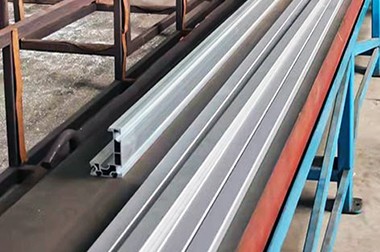

7175 aluminum alloy profiles are typically processed into various shapes, such as sheets, profiles, and tubes, through extrusion, rolling, and other methods. These profiles can be precision cut and shaped according to specific design requirements to fit different components of aircraft.

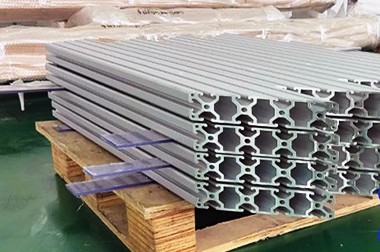

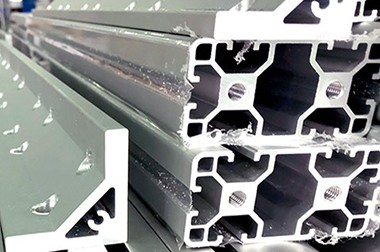

Haomei 7175 aluminum alloy profile hot-selling products

Haomei Aluminum 7175 aluminum profile is an aluminum profile made of 7175 aluminum alloy. The common ones are round tube, square tube, rectangular tube, angle bar, T profile, U profile, etc. The size can vary according to different application requirements.

7175 T6 Aluminum Profiles Extrusions

The characteristics of 7175 T6 aluminum profiles include a high strength-to-weight ratio and excellent fatigue resistance. The T6 state indicates that the aluminum has undergone solution heat treatment and artificial aging, which enhances its mechanical properties. This state provides good machinability and weldability, making it suitable for various structural components.

Aerospace Applications of 7175 T6 Aluminum Profiles Extrusions

In the aerospace field, 7175 T6 aluminum profiles are primarily used for:

- Aircraft Structural Components: Due to their high strength and lightweight properties, they can be used for fuselage frames, wings, and tail assemblies.

- Landing Gear Components: Provide the necessary strength and durability to withstand impacts during landing.

- Support Structures: Used for aircraft fixtures and brackets that require high strength without adding excessive weight.

7175 T73511 Aluminum Profiles Extrusions

7175 T73511 aluminum profiles undergo a special heat treatment process that improves their stress corrosion resistance and enhances overall mechanical performance. This state is designed for critical applications where reducing sensitivity to stress corrosion cracking is vital. The strength of T73511 state is typically lower than that of T6 state, but it has better toughness and environmental resistance.

Aerospace Applications of 7175 T73511 Aluminum Profiles Extrusions

In the aerospace field, 7175 T73511 aluminum profiles are typically used for:

- Fuselage Components: Particularly suitable for areas of the fuselage where stress corrosion resistance is crucial, such as those exposed to high humidity or corrosive environments.

- Aircraft Repair Parts: Frequently used in repair applications where enhanced toughness is needed to maintain structural integrity.

- High-Performance Aircraft: Used for components in military and high-performance aircraft, where reliability and durability under harsh conditions are essential.

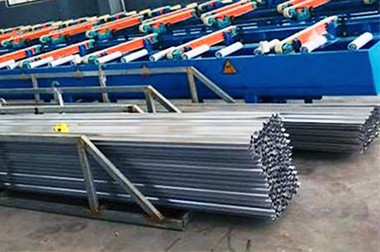

7175 Aluminum Extrusions Round Tubes

Round tubes made from 7175 aluminum alloy have a cylindrical shape and uniform wall thickness. They can be extruded into various diameters and lengths, providing versatility for different structural applications.

Aerospace Applications of 7175 Aluminum Extrusions Round Tubes:

Hydraulic Lines: Due to their ability to withstand high pressure, they are used for routing hydraulic oil and other systems.

7175 Aluminum Extrusions Rectangular Tubes

Rectangular tubes have a rectangular cross-section and are known for their excellent strength and rigidity. Their length and thickness can be customized according to application requirements.

Aerospace Applications of 7175 Aluminum Extrusions Rectangular Tubes:

- Structural Beams: Often used as beams and frames in aircraft structures, providing necessary support for various aircraft components.

- Cargo Bays: Used in the construction of cargo bays, ensuring durability while maintaining weight efficiency.

7175 Aluminum Extrusions Angle Bars

Angle bars, also known as angle profiles, consist of two perpendicular legs that form an L-shaped cross-section. They can be extruded in different leg lengths and thicknesses.

Aerospace Applications of 7175 Aluminum Extrusions Angle Bars:

- Brackets and Mounts: Used for brackets, supports, and other structural connections that require strength and stability.

- Reinforcement: Commonly used to reinforce corners and edges of structures, enhancing overall rigidity.

7175 Aluminum Extrusions T Profiles

T profiles have a T-shaped cross-section and are known for their high strength-to-weight ratio. These profiles can be customized in height and width to suit specific design requirements.

7175 Aluminum Extrusions T Profiles Applications in Aviation

- Wing Ribs: Frequently used in wing rib structures, providing essential support while maintaining aerodynamic efficiency.

- Framework Components: Employed in various framework components of the aircraft where strength and lightness are crucial.

7175 Aluminum Extrusions U Profiles

U profiles have a U-shaped cross-section and are available in various depths and widths. They are recognized for their structural stability and can be used in various configurations.

7175 Aluminum Extrusions U Profiles Applications in Aviation:

- Structural Frames: Used in the construction of frames for the aircraft’s body and other critical components.

- Guiding Rails: Often employed as guiding rails for movable parts, ensuring smooth operation and structural integrity.

Chemical composition of 7175 aluminum alloy profiles

| Element | Percentage |

| Al | 88.6-90.6% |

| Zn | 5.0-6.0% |

| Mg | 1.9-2.6% |

| Cu | 1.4-2.0% |

| Fe | 0.5% max |

| Mn | 0.3% max |

| Si | 0.20-0.80% |

| Cr | 0.18-0.28% |

| Ti | 0.06-0.20% |

Physical properties of 7175 aluminum alloy profiles

| Property | Value |

| Density | 2.70 g/cm3 |

| Melting point | 582-652°C |

| Tensile strength | 90-120 MPa |

| Yield strength | 50-80 MPa |

| Elongation | 15-25% |

| Hardness (Brinell) | 25-45 HB |

| Thermal conductivity | 180-210 W/mK |

| Electrical conductivity | 34-40 MS/m |

| Coefficient of thermal expansion | 23.1×10-6 /°C |

Dimensions of 7175 aluminum alloy profiles

| Extrusion type | Dimension range (inches) | Wall thickness range (inches) |

| Round Tube | 1-10 | 0.125-0.75 |

| Square Tube | 1-8 | 0.125-0.5 |

| Rectangular Tube | 1*2-8*12 | 0.125-0.5 |

| Angle | 1*1-8*8 | 0.125-0.5 |

| T-Profile | 1*1-6*6 | 0.125-0.5 |

| U-Profile | 1*0.5-6*2 | 0.125-0.5 |

Specific Applications of 7175 Aluminum Profiles in the Aerospace Field

1. Aerospace Structural Components

7175 aluminum profiles are widely used in the primary structural components of aircraft, such as wing frames, fuselage structures, and tail assemblies. These components must meet high strength and stiffness requirements to ensure flight safety and performance. The tensile and compressive strength of 7175 aluminum profiles make them ideal materials for meeting these stringent requirements. Additionally, the corrosion resistance of this alloy helps extend the lifespan of the aircraft.

2. Wing Components

In wing design, 7175 aluminum profiles are used to manufacture critical components such as spars and ribs. Spars are essential parts that support the wing structure and must possess extremely high strength and stiffness to resist various loads during flight. Ribs provide the shape and aerodynamic performance of the wing. The lightweight characteristics of 7175 aluminum profiles can reduce the overall weight of the wing, thereby improving the aircraft's fuel efficiency and flight performance.

3. Landing Gear

The landing gear is a key component of the aircraft that withstands immense impact forces during landing. Due to its excellent strength and toughness, 7175 aluminum profiles are often used in certain components of the landing gear, such as support arms and connectors. These components face significant dynamic loads during takeoff and landing, so their strength and durability are crucial. The application of 7175 aluminum profiles not only enhances the load-bearing capacity of the landing gear but also effectively resists fatigue and wear, ensuring a safe and reliable landing.

4. Aircraft Accessories

7175 aluminum profiles can also be used for various aircraft accessories and fittings, such as door frames, seat supports, and cargo bay supports. Although these components do not bear the same level of forces as primary structural components, they still require lightweight construction and a certain level of strength to ensure the overall safety and performance of the aircraft. The use of 7175 aluminum profiles can meet strength requirements while reducing overall weight.

5. Support Structures

7175 aluminum alloy is also used as support structures and connectors to ensure the overall structural integrity of the aircraft. It plays a vital role in cabin structures, fuselage connectors, and system support structures, helping to distribute loads and provide the necessary stiffness and stability. The strength and lightweight design of these support structures directly impact the performance and efficiency of the aircraft.